Heat-resistant chemiluminescent composition

A chemiluminescence and composition technology, which is applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of deterioration of oxidants and failure of normal use of fluorescent rods, and achieve the effect of avoiding deterioration by heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

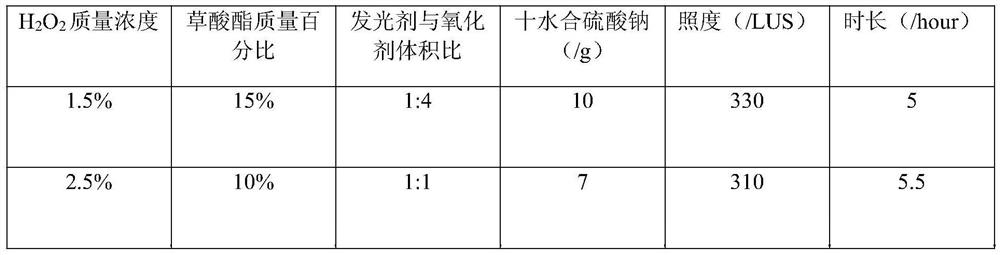

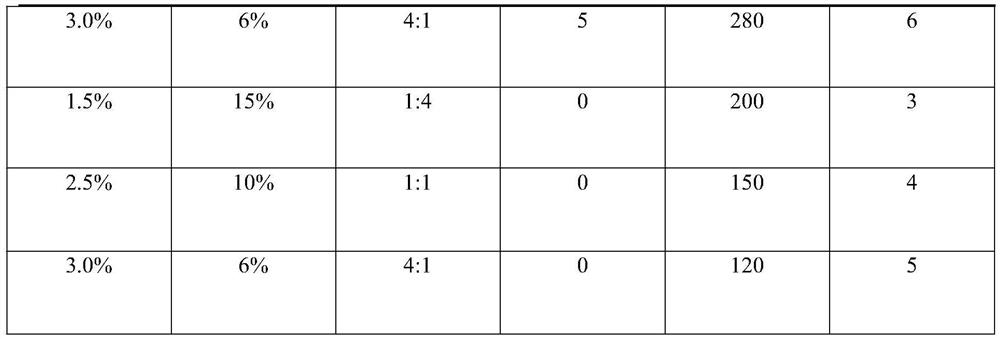

Embodiment 1

[0008] (1) Preparation of luminescent agent:

[0009] Dissolve 3.75 g of bis(2,4,5-trichlorosalicylate n-pentyl) oxalate (CPPO) and 0.075 g of 9,10(diethynyl)anthracene in tributyl citrate and butyl benzoate In the mixed solution, stir until completely dissolved to obtain a luminescent agent; wherein, the mass ratio of tributyl citrate and butyl benzoate is 6:4; the mass percent concentration of oxalate ester components is 15%, 9,10 The mass percent concentration of (diethynyl)anthracene is 0.30%.

[0010] (2) Preparation of oxidizing agent:

[0011] 1.5g hydrogen peroxide and 0.0025g tetrabutylamine salicylate are dissolved in glyceryl triacetate and stirred to obtain an oxidizing agent; wherein, the mass percent concentration of hydrogen peroxide is 1.5%, and the mass percent of tetrabutylamine salt The percentage concentration is 0.0025%.

[0012] (3) Combination and testing of chemiluminescent substances

[0013] Mix the luminescent agent in step (1) with the oxidant i...

Embodiment 2

[0015] (1) Preparation of luminescent agent:

[0016] Dissolve 2.5 g of bis(2,4,5-trichlorosalicylate n-pentyl) oxalate (CPPO) and 0.06 g of 9,10(diethynyl)anthracene in tributyl citrate and butyl benzoate In the mixed solution, stir until it is completely dissolved to obtain a luminescent agent; wherein, the mass ratio of tributyl citrate and butyl benzoate is 6:4; the mass percent concentration of oxalate is 10%, 9,10 The mass percent concentration of (diethynyl) anthracene is 0.24%;

[0017] (2) Preparation of oxidizing agent

[0018] 2.5g hydrogen peroxide and 0.01g tetrabutylamine salicylate are dissolved in glyceryl triacetate and stirred to obtain an oxidizing agent; wherein, the mass percent concentration of hydrogen peroxide is 2.5%, and the mass percent of tetrabutylamine salt The percentage concentration is 0.013%.

[0019] (3) Combination and testing of chemiluminescent substances

[0020] Mix the luminescent agent in step (1) with the oxidizing agent in step (...

Embodiment 3

[0022] (1) Preparation of luminescent agent:

[0023] Dissolve 6g (2,4,5-n-pentyl trichlorosalicylate) oxalate (CPPO) and 0.16g bis(phenylethynyl)anthracene in the mixture of tributyl citrate and butyl benzoate , stirred until completely dissolved to obtain a luminescent agent; wherein, the mass ratio of tributyl citrate and butyl benzoate is 7:2; the mass percent concentration of oxalate ester components is 6%, 9,10 (diethynyl ) The mass percent concentration of anthracene is 0.16%.

[0024] (2) Preparation of oxidizing agent:

[0025] 0.75g hydrogen peroxide and 0.04g tetrabutylamine salicylate are dissolved in glyceryl triacetate and stirred to obtain an oxidizing agent; wherein, the mass percent concentration of hydrogen peroxide is 3.0%, and tetrabutylamine salicylate The mass percent concentration of salt is 0.04%.

[0026] (3) Combination and testing of chemiluminescent substances

[0027] Mix the luminescent agent in step (1) with the oxidizing agent in step (2), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com