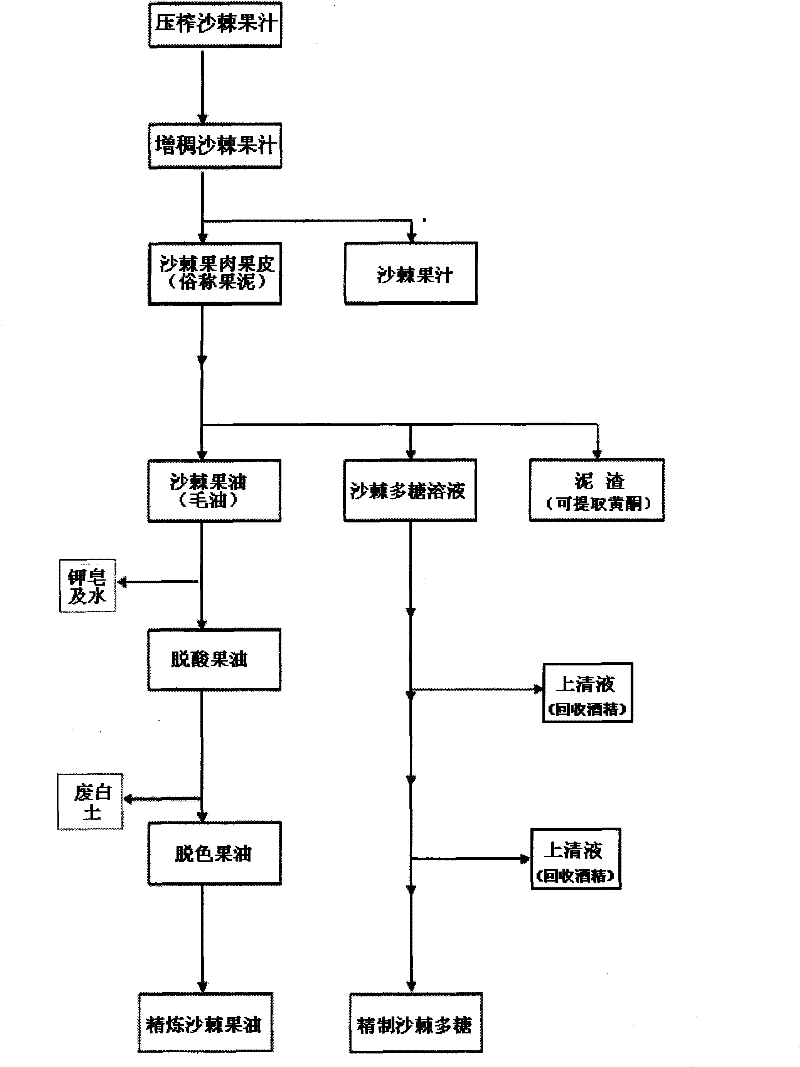

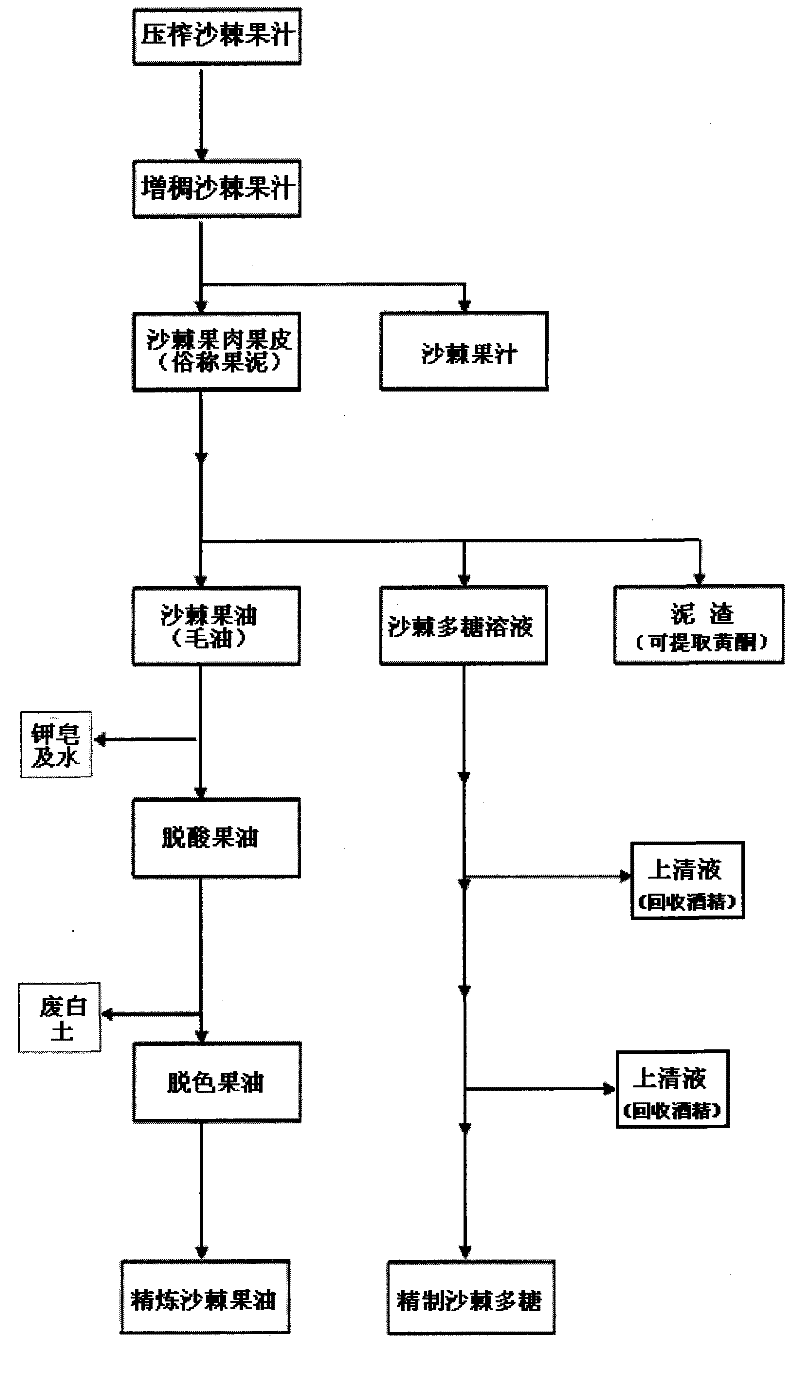

Co-production extract method of fruit oil and polysaccharide from seabuckthorn fruit paste

A technology for co-production extraction and sea buckthorn fruit, which is applied in the directions of fat oil/fat production, fat production, and pharmaceutical formulations, can solve the problems of long production cycle, low fruit oil yield, and large occupied area, and achieves safe and reasonable production process. The effect of saving production area and fast production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for extracting fruit oil and polysaccharide coproduction in seabuckthorn puree of the present invention comprises the following steps:

[0031] (1) Thickening: Pressed seabuckthorn fresh juice is placed in a cold storage at -3°C for natural settlement, and the peel and pulp settle to the bottom of the storage tank to obtain thickened seabuckthorn juice;

[0032] (2) Juice separation: thicken seabuckthorn juice at room temperature, use a horizontal sedimentation centrifuge to separate the juice and peel pulp, the juice can still be used to produce seabuckthorn series products;

[0033](3) Oil analysis of fruit puree: Add 3 times the amount of deionized water to the seabuckthorn peel and pulp, stir evenly, stir and heat until boiling, and keep boiling for 8 minutes. During this process, the cell wall is broken by heating, and the fruit oil is released from the oil chamber. in precipitation;

[0034] (4) Solid-liquid separation: keep the temperature at 60°C, sepa...

Embodiment 2

[0043] A method for extracting fruit oil and polysaccharide coproduction in seabuckthorn puree of the present invention comprises the following steps:

[0044] (1) Thickening: Pressed seabuckthorn fresh juice is placed in a cold storage at 0°C for natural settlement, and the peel and pulp settle to the bottom of the storage tank to obtain thickened seabuckthorn juice;

[0045] (2) Juice separation: thicken seabuckthorn juice at room temperature, use a horizontal sedimentation centrifuge to separate the juice and peel pulp, the juice can still be used to produce seabuckthorn series products;

[0046] (3) Oil analysis of fruit puree: add 3 times the amount of deionized water to the seabuckthorn peel and pulp, stir evenly, stir and heat to boiling, and keep boiling for 10 minutes. In this process, the cell wall is broken by heating, and the fruit oil is released from the oil chamber. in precipitation;

[0047] (4) Solid-liquid separation: keep the temperature at 70°C, separate t...

Embodiment 3

[0056] A method for extracting fruit oil and polysaccharide coproduction in seabuckthorn puree of the present invention comprises the following steps:

[0057] (1) Thickening: Pressed seabuckthorn fresh juice is placed in a cold storage at 3°C for natural settlement, and the peel and pulp settle to the bottom of the storage tank to obtain thickened seabuckthorn juice;

[0058] (2) Juice separation: thicken seabuckthorn juice at room temperature, use a horizontal sedimentation centrifuge to separate the juice and peel pulp, the juice can still be used to produce seabuckthorn series products;

[0059] (3) Oil analysis of fruit puree: add 3 times the amount of deionized water to the seabuckthorn peel and pulp, stir evenly, stir and heat to boiling, and keep boiling for 12 minutes. In this process, the cell wall is broken by heating, and the fruit oil is released from the oil chamber in precipitation;

[0060] (4) Solid-liquid separation: keep the temperature at 80°C, use a dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com