Magnetic-suspension driving energizer

A technology of energizers and maglevs, applied in the direction of magnetic attraction or thrust holding devices, electrical components, etc., can solve problems such as inability to perform circular motion, increase output energy, and affect energy efficiency, so as to reduce consumption and make great contributions , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

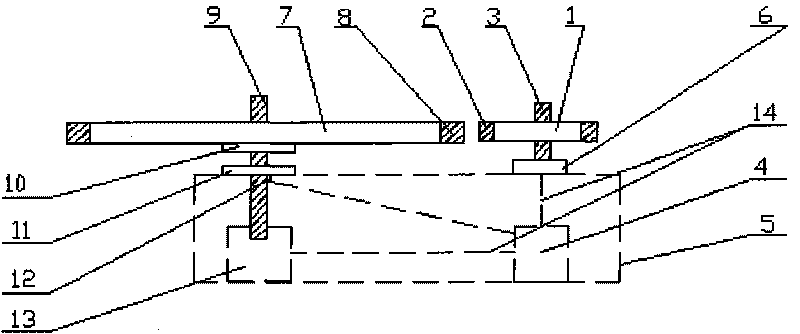

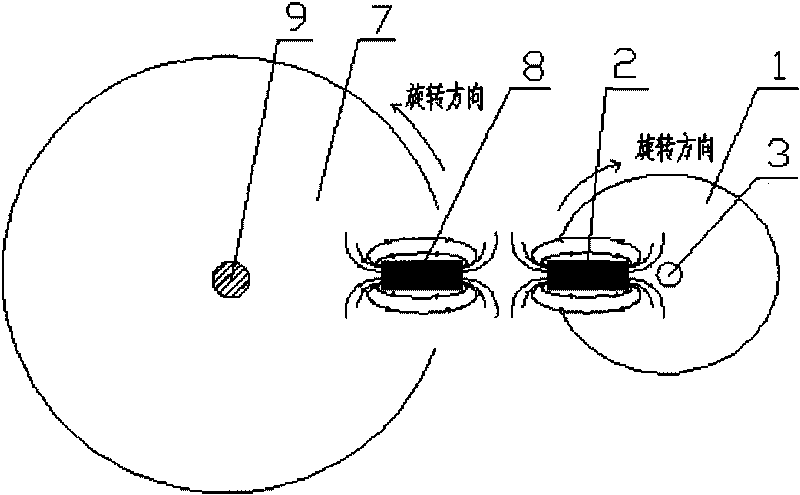

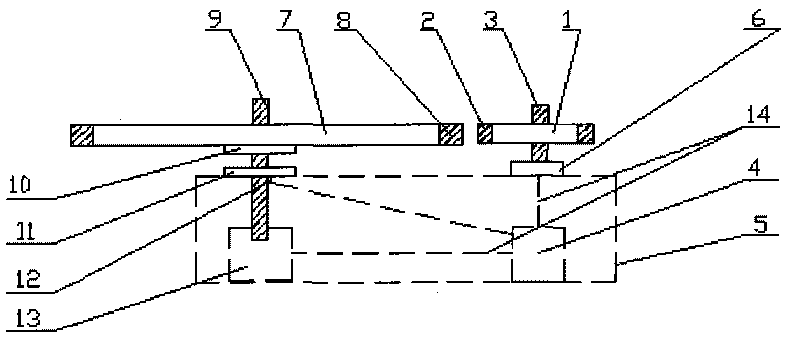

[0018] Such as figure 1 , 2 , a magnetic levitation energizer, mainly composed of a driving small plate 1 with a small plate magnetic block 2, a driven large plate 7 with a large plate magnetic block 8, a starting device 6, an upper magnetic levitation ring 10, a lower magnetic levitation ring 11, and a drive shaft 3 , a driven shaft 9, a support frame 5, a load 13, and an energy storage control device.

[0019] The small disc magnetic block 2 is installed on the outer circumference of the small drive disc. The drive disc is an artificial composite material disc in a horizontal position. The drive shaft 3 arranged vertically is connected with the starting device 6. The rotation of the starting device drives the drive small disc to make a horizontal position. circular motion.

[0020] The large disk magnetic block 8 is installed on the outer circumference of the driven large disk, and the magnetic surface with the same polarity as the magnetic pole of the small disk magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com