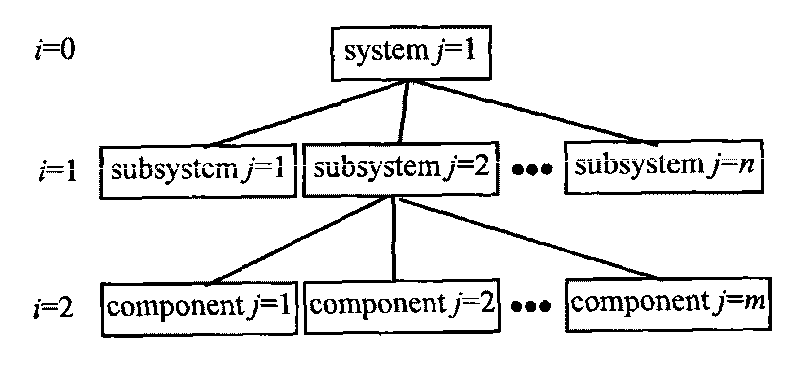

Layering modeling and optimizing method targeting complicated manufacture system

A technology of manufacturing systems and optimization methods, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as solution limitations, achieve high flexibility, and reduce the effect of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

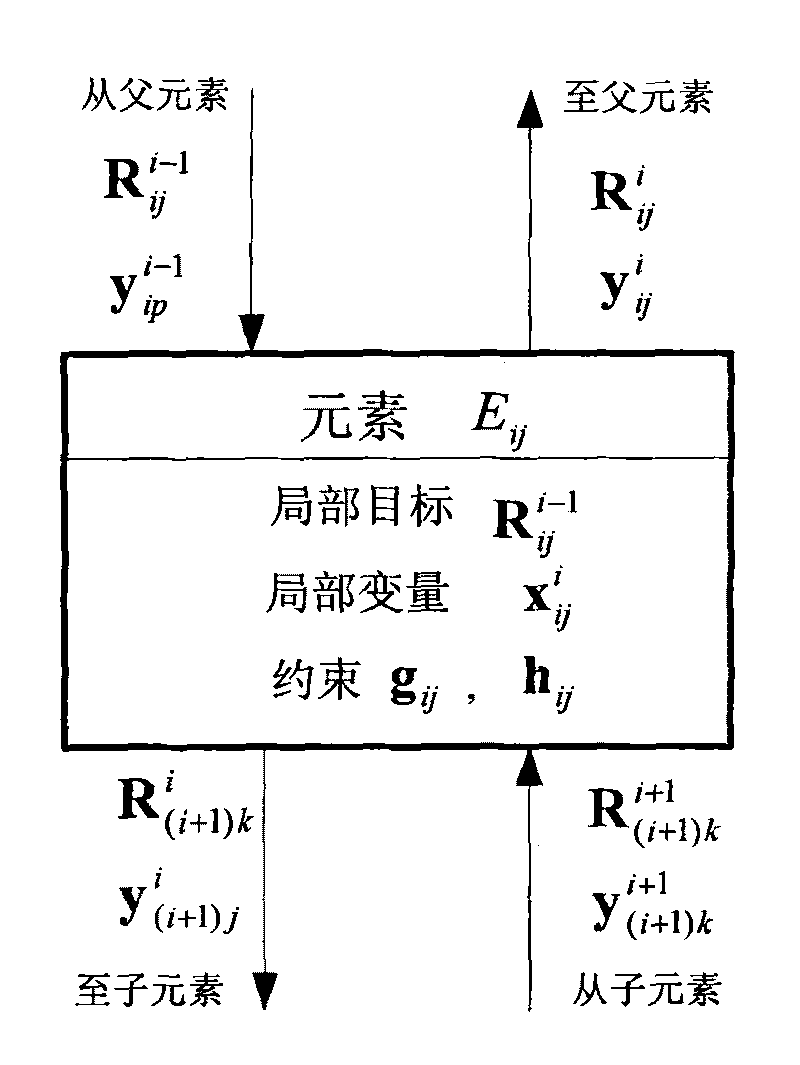

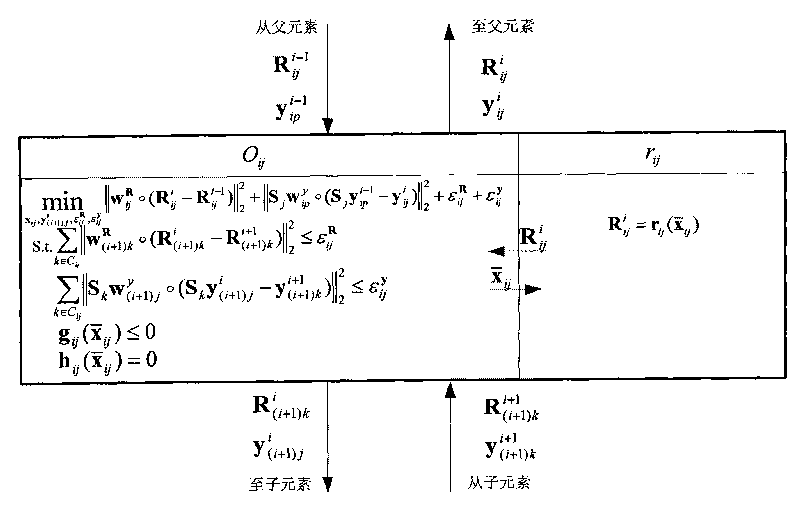

Method used

Image

Examples

Embodiment 1

[0070] Example 1: Solving the two-tier job scheduling optimization problem

[0071] The shop described in this example has two part families (consisting of parts with similar processing routes) that need to be machined. There are 6 types of machines in the whole workshop, called A, B, C, D, E, and F. There are 8 machines for each type, and there are 48 processing machines in total. Each part family has 6 types of workpieces , its process constraints, processing time (data in brackets) and number of workpieces are shown in Table 1 and Table 2, respectively:

[0072] Table 1 Parts to be processed in part family 1

[0073]

[0074] Table 2 Parts to be processed in part family 2

[0075]

[0076] The workshop scheduling described here is divided into Figure 5 Two layers are shown: the part family planning layer and the part planning layer. The task of the part family planning layer is to complete the equipment planning of the whole workshop, and the task of the part pla...

Embodiment 2

[0093] Example 2: Optimal solution to the three-tier job scheduling problem

[0094] The workpiece processing procedures, machine tools and corresponding processing time involved in the workshop scheduling are shown in Table 4. In the table, Pij represents the jth processing procedure of workpiece i, such as P12 represents the second processing procedure of workpiece 1.

[0095] Scheduling objectives include optimization of processing time (minimum completion time) and optimization of processing costs.

[0096] Table 4 Instance data of a scheduling problem

[0097]

[0098] It is known that the processing costs of machines M1, M2, M3, M4, and M5 are 80 yuan / h, 100 yuan / h, 120 yuan / h, 90 yuan / h, and 60 yuan / h, and workpieces 1, 2, 3, and 4 , 5, 6, 7 and 8 delivery deadlines are 40h, 35h, 50h, 40h, 43h, 35h, 53h and 43h respectively, and the total processing cost is limited to less than 15,500 yuan.

[0099] According to the aforementioned solution methods and steps, the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com