Method for analyzing glass fiber in paper

A technology of glass fiber and analysis method, which is applied in the analysis field of glass fiber in paper, can solve the problems of separation, expensive equipment, difficulty, etc., and achieve the effect of good analysis effect, low application cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

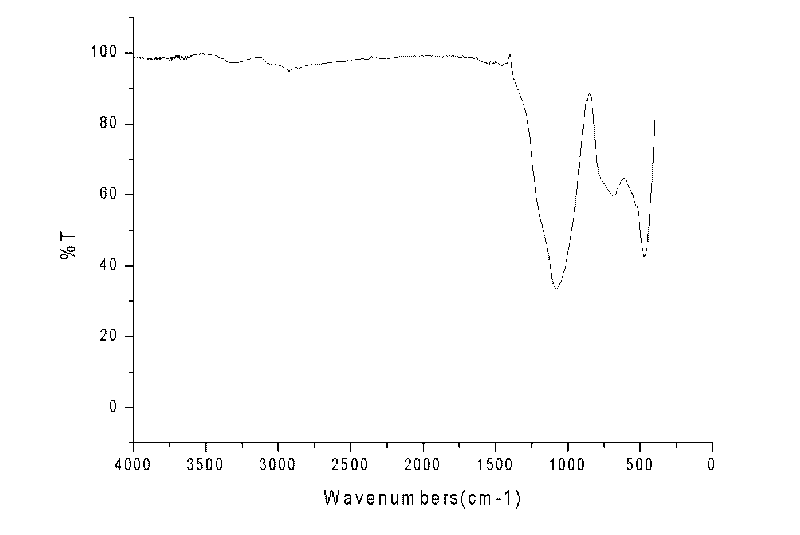

Image

Examples

Embodiment 1

[0018] In this embodiment, the glass fiber in the paper is analyzed, and the sample used is a sample paper with known content (glass fiber content: 0.13%).

[0019] Instruments used: muffle furnace, oven, integrated filter (including: glass crucible (with sand core, specification: 40-60μm), water flushing vacuum pump, fixed bracket, etc.)

[0020] Concentrated acid solution: concentrated hydrochloric acid, 12mol / L

[0021] Deionized water

[0022] Analysis steps:

[0023] Weigh 6.2024g paper sample.

[0024] After being ignited, let it burn out, and move all the ash into a glass crucible (crucible weight: 29.4173g).

[0025] Calcined in a muffle furnace at 500°C for 8h, and cooled to room temperature naturally in the muffle furnace.

[0026] Rinse the sample ash residue with 50ml / L concentrated hydrochloric acid three times, soak in concentrated hydrochloric acid for 1 hour, then filter and rinse with deionized water.

[0027] Put it in an oven at 120°C for 2 hours, take ...

Embodiment 2

[0030] In this embodiment, the glass fiber in the paper is analyzed, and the sample used is a cigarette-like paper with known glass fiber content (glass fiber content: 1.25%) and other partially acid-soluble fiber content.

[0031] Instruments used: muffle furnace, oven, integrated filter (including: glass crucible (with sand core, specification: 40-60μm), water flushing vacuum pump, fixed bracket, etc.)

[0032] Concentrated acid solution: concentrated hydrochloric acid, 12mol / L

[0033] Deionized water

[0034] Analysis steps:

[0035] Weigh 6.5526g paper sample.

[0036] After being ignited, let it burn out, and move all the ash into a glass crucible (crucible weight: 29.7178g).

[0037] Calcined in a muffle furnace at 500°C for 8h, and cooled to room temperature naturally in the muffle furnace.

[0038] Observed with a polarizing microscope, it was found that other fibers were present at the same time.

[0039] Rinse the sample ash residue with 50ml / L concentrated hyd...

Embodiment 3

[0043] In this embodiment, the glass fiber in the paper is analyzed, and the sample used is a sample paper with known content (glass fiber content: 0.48%).

[0044] Instruments used: muffle furnace, oven, integrated filter (including: glass crucible (with sand core, specification: 40-60μm), water flushing vacuum pump, fixed bracket, etc.)

[0045] Concentrated acid solution: concentrated nitric acid, 16mol / L

[0046] Deionized water

[0047] Analysis steps:

[0048] Weigh 6.6898g paper sample.

[0049] After being ignited, let it burn out, and move all the ash into a glass crucible (crucible weight: 30.0802g).

[0050] Calcined in a muffle furnace at 500°C for 8h, and cooled to room temperature naturally in the muffle furnace.

[0051] Rinse the sample ash with 50ml / L concentrated nitric acid three times, soak in concentrated nitric acid for 1 hour, then filter and rinse with deionized water.

[0052] Put it in an oven at 120°C for 2 hours, take it out and put it in a dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com