Masonry structure for 18TAOD furnace lining

A technology of masonry structure and furnace lining, applied in the direction of lining repair, etc., can solve the problems of reducing the volume of the furnace chamber, accelerating the erosion of the upper furnace lining, waste of materials, etc., to achieve uniform erosion of the furnace wall, avoid uneven erosion, and reduce production costs.

Active Publication Date: 2010-06-09

YONGXING SPECIAL STAINLESS STEEL

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this scheme is that only the furnace lining in the wind eye area is thickened, without considering the different degrees of erosion in other parts; on the other hand, if the thickness of the furnace lining in the wind eye area is increased to the original 1.5 to 2 times, it will actually cause waste of materials, and reduce the volume of the furnace, so that the molten steel level rises, and accelerate the erosion of the upper furnace lining

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

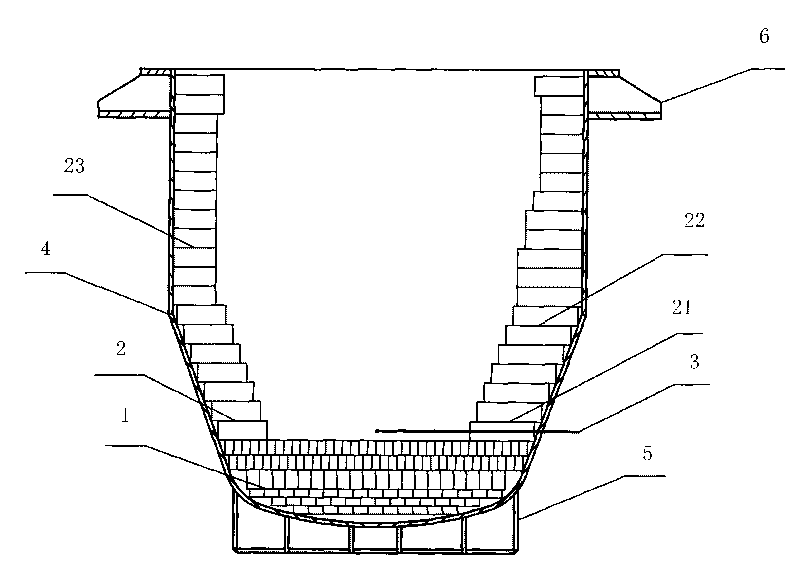

The invention belongs to the technical field of steelmaking converters, in particular to a masonry structure for an 18TAOD furnace lining, which comprises a furnace bottom and a furnace wall; the bottom of the furnace wall is provided with a blower gun; an area spread in a sector shape on the upper part of the blower gun on the furnace wall is an airhole area; the first layer, the second laeyr and the third layer of the airhole area are made of magnesite-chrome bricks; the fourth layer, the fifth layer, the sixth layer, the seventh layer, the eighth layer, the ninth layer and the tenth layer are made of high-purity magnesia-calcium bricks; and the eleventh layer, the twelveth layer, the thirteenth layer, the fourteenth layer, the fifteenth layer, the sixteenth layer, the seventeenth layer, the eighteenth layer and the nineteenth layer and other furnace wall are made of common magnesia-calcium bricks. In the masonry structure, the whole furnace lining is basically uniform through reasonable use of refractory bricks made of different materials in different areas so as to achieve the aims of improving the furnace life and reducing the cost.

Description

technical field [0001] The invention belongs to the technical field of steelmaking converters, in particular to a masonry structure of 18TAOD furnace lining. Background technique [0002] AOD is the abbreviation of Argon Oxygen Decarburization. It adopts normal pressure operation, and there are multiple tuyeres on one side of the furnace body. Oxygen, argon and nitrogen can be delivered to the furnace through the tuyeres. During operation, the type and volume of gas supplied can be adjusted to reduce CO emissions. Partial pressure is an important refining method to achieve the purpose of reducing carbon and maintaining chromium. The AOD furnace mainly includes the furnace shell and the furnace lining. The furnace lining material is required to be able to withstand high temperature and severe temperature fluctuations, chemical erosion of slag and mechanical erosion of molten steel. [0003] In the two-step smelting of stainless steel, the refractory bricks in the working la...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27D1/16C21C7/068

Inventor 邹伟民丁斌华王建勇

Owner YONGXING SPECIAL STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com