Thermo-acoustic refrigerator device driven by cascade thermo-acoustic engine

A thermoacoustic engine and thermoacoustic refrigerator technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems that restrict the wide application of thermally driven thermoacoustic refrigerators, it is difficult to overcome the sound DC loss, and the system efficiency is affected. and other problems, to avoid the loss of acoustic circulation, improve the actual efficiency, and achieve the effect of high-efficiency thermoacoustic conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

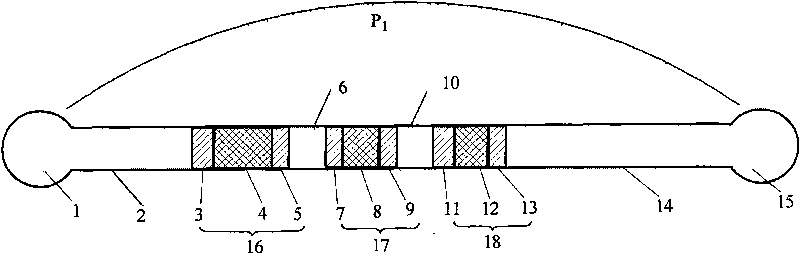

[0032] The structure of this embodiment is as figure 1 shown, where P 1 It is the oscillation pressure amplitude, which includes the engine-level terminal resonant cavity 1, the engine-level resonant tube 2, and the standing wave-level engine unit 16 connected in sequence (including: room temperature end cooler 3, regenerator 4, high temperature end heater 5) , thermal buffer tube 6 in the standing wave band, engine unit 17 at the traveling standing wave level (comprising: room temperature side cooler 7, regenerator 8, high temperature side heater 9), thermal buffer tube 10 in the traveling band band, and traveling standing wave level refrigerator unit 18 (including: room temperature end cooler 11 , regenerator 12 , low temperature end heat exchanger 13 ), refrigerator-level resonance tube 14 and refrigerator-level terminal resonance cavity 15 .

[0033] In this embodiment, the sound work is initially generated in the thermoacoustic unit 16 working under the standing wave mec...

Embodiment 2

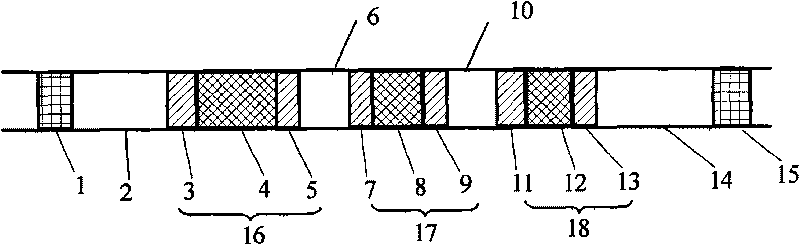

[0039] The structure of this embodiment is as figure 2 As shown, it includes sequentially connected engine-level moving piston 1, engine-level resonant tube 2, standing-wave-level engine unit 16 (comprising: room temperature end cooler 3, regenerator 4, high-temperature end heater 5), standing wave section heat sink Buffer tube 6, traveling standing wave engine unit 17 (including: room temperature end cooler 7, regenerator 8, high temperature end heater 9), traveling wave heat buffer pipe 10, traveling standing wave refrigerator unit 18 (including: Room temperature end cooler 11 , regenerator 12 , low temperature end heat exchanger 13 ), refrigerating machine level resonant tube 14 and refrigerating machine level moving piston 15 .

[0040] In this embodiment, by adjusting the working frequency and phase angle relationship between the moving piston 1 of the engine stage and the moving piston 15 of the refrigerator stage, the boundary conditions of the sound field in the syste...

Embodiment 3

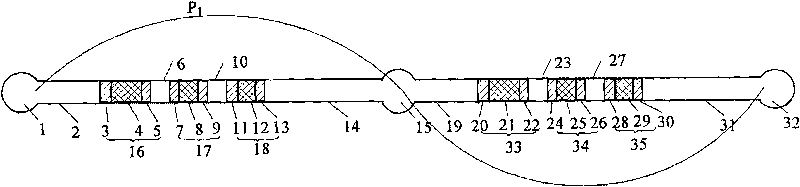

[0046] The structure of this embodiment is as image 3 shown, where P 1 is the amplitude of the oscillating pressure, which includes a first-level engine-level terminal resonant cavity 1, a first-level engine-level resonant tube 2, and a standing-wave level engine unit 16 (including: room temperature end cooler 3, regenerator 4, Heater 5 at the high temperature end, heat buffer tube 6 for the first-stage standing wave band, engine unit 17 for the first-stage traveling standing wave stage (including: room temperature end cooler 7, regenerator 8, high-temperature end heater 9), first-stage traveling wave band Thermal buffer tube 10, primary standing wave refrigerator unit 18 (including: room temperature end cooler 11, regenerator 12, low temperature end heat exchanger 13), primary refrigerator stage resonant tube 14, resonant cavity 15, Secondary engine level resonance tube 19, secondary standing wave level engine unit 33 (including: room temperature end cooler 20, regenerator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com