Plastic corrugated pipe connecting device as well as molding method and molding device thereof

A technology of connecting device and forming device, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fittings, tubular articles, etc., can solve the problems of reduced pipe production stability, large investment, and unacceptable users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

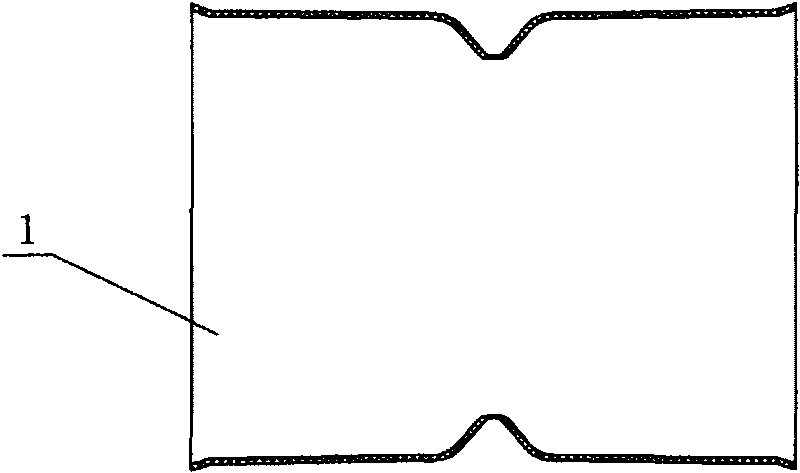

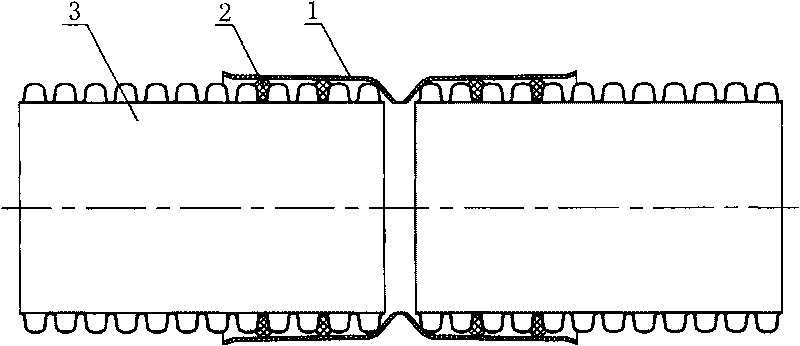

[0022] Such as figure 1 and figure 2 As shown, the plastic corrugated pipe connection device 1 is used to connect the plastic corrugated pipe 3 without flare. An inwardly recessed positioning portion is provided at the middle portion corresponding to the seam of the bellows. The pipes on both sides of the pipe body are respectively bell-shaped, and the two ends of the pipe body are respectively provided with flared openings for the insertion of bellows. A seal ring 2 is embedded in the wave groove at the joint end of the bellows. After the bellows is inserted into the bellows connecting device 1, the seal ring 2 is closely attached to the bell-shaped pipe.

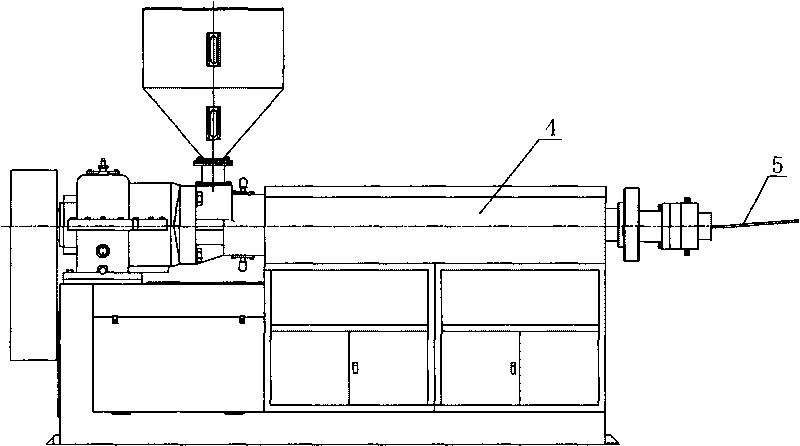

[0023] The molding method of the plastic corrugated pipe connection device is to extrude the plastic strip 5 through the extruder 4. The cross section of the plastic strip 5 is flat, and the plastic strip 5 is wound on the forming mandrel by a winding machine 6. 7, and multiple layers are wound on the forming mandrel 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com