Pump for smashing sewages

A technology for crushing pumps and dirt, applied in the direction of pumps, grain processing, non-variable-capacity pumps, etc., can solve the problems of dirt slippage, accumulation, insufficient dirt crushing, affecting sewage discharge, etc., and achieve sewage efficiency. High, improve the crushing rate, the effect of strong crushing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

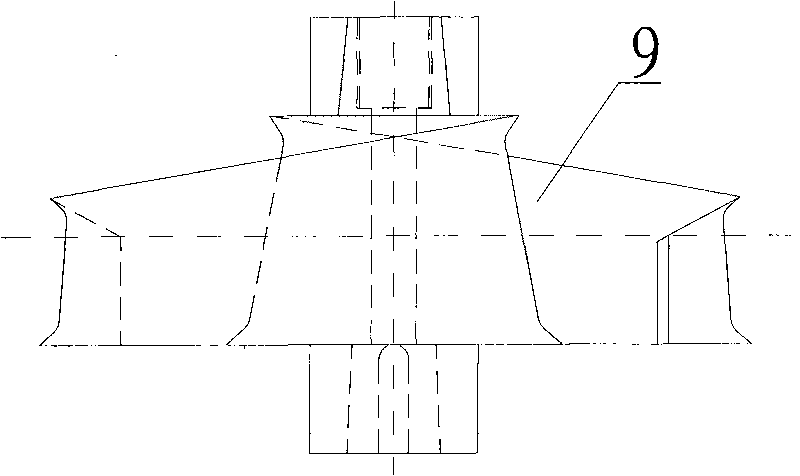

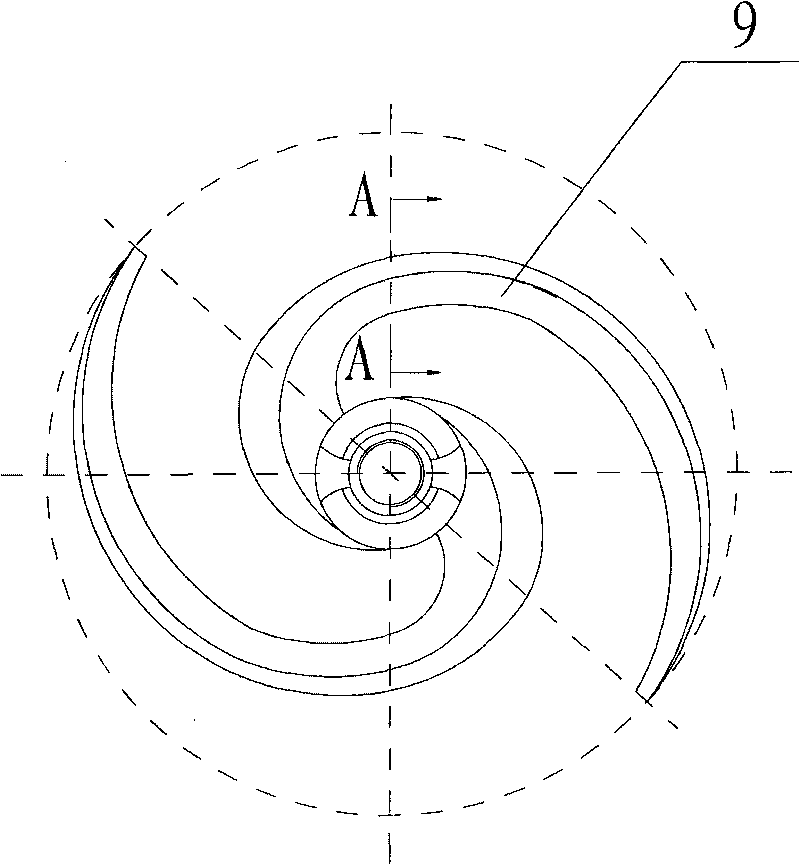

[0026] Such as Figure 1 to Figure 9 As shown, the sewage crushing pump includes a transmission shaft 2, a crushing device 3 and a pump body 1, and a long casing 4 is arranged outside the transmission shaft 2, and the top of the long casing 4 is fixed with a connecting seat 5 for connecting the motor, The upper cover 6 connected to the pump body 1 is fixed at the bottom, and the crushing device 3 includes an impeller 8 connected to the lower end of the transmission shaft 2 through a bushing 7, and two arcs in the shape of an involute are oppositely arranged on the impeller 8 Shaped blade 9, the lower end of the blade 9 is provided with a blade 13, the bottom of the pump body 1 is provided with a bottom cover 11, the bottom cover 11 is provided with a triangular water inlet 12, and the upper end of the blade 9 is also provided with There is a blade 13, and the crushing device 3 also includes an inner plate 10 fixed on the bottom of the upper cover 6 and sleeved on the impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com