Blast-furnace vent device

A technique of stabbing tuyeres and blast furnaces, applied in tuyeres and other directions to achieve the effect of high power and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

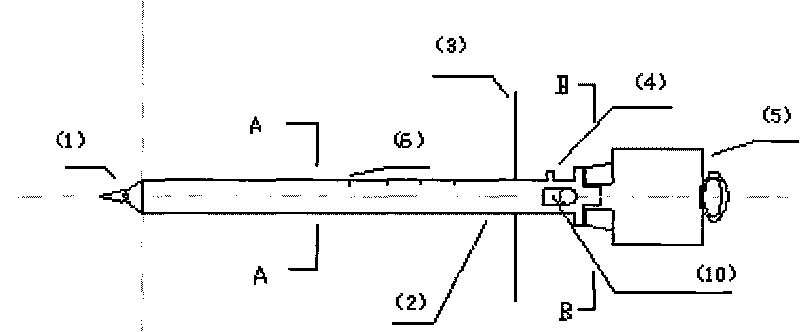

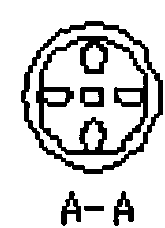

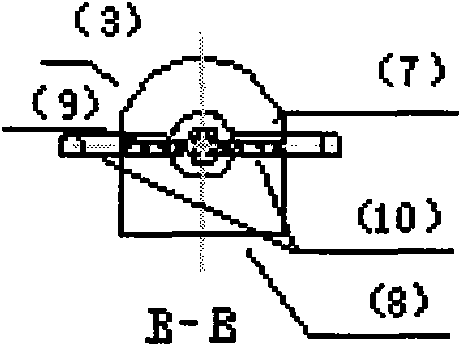

[0023] like figure 1 , figure 2 and image 3 As shown, a blast furnace tuyere device includes a cone head 1, a hollow steel pipe 2, a protective plate 3, a compressed air interface 4, an air hammer 5, a transparent plexiglass window 7, an iron plate 8, a screw 9 and an inverted rod 10, There are 4 holes on the cone head 1, the head of the hollow steel pipe 2 is welded to the cone head 1, the inside is connected with 0.6Mpa compressed air, the middle and rear part is provided with a protective plate 3, the upper part is Transparent plexiglass window 7, the lower half is iron plate 8.

[0024] The compressed air enters through the compressed air interface 4 arranged at the rear of the hollow steel pipe 2, and is connected by a detachable hose.

[0025] The tail of the hollow steel pipe 2 is connected to the detachable air hammer 5 , and the inverted rod 10 is vertically inserted into the front of the air hammer 5 and the hollow steel pipe 2 and fixed by screws 9 .

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com