Production method of needle coke

A production method and needle coke technology, applied in coke ovens, coking carbonaceous materials, petroleum industry, etc., can solve the problems of high cost and large investment, and achieve the effects of low cost, expansion of sources and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

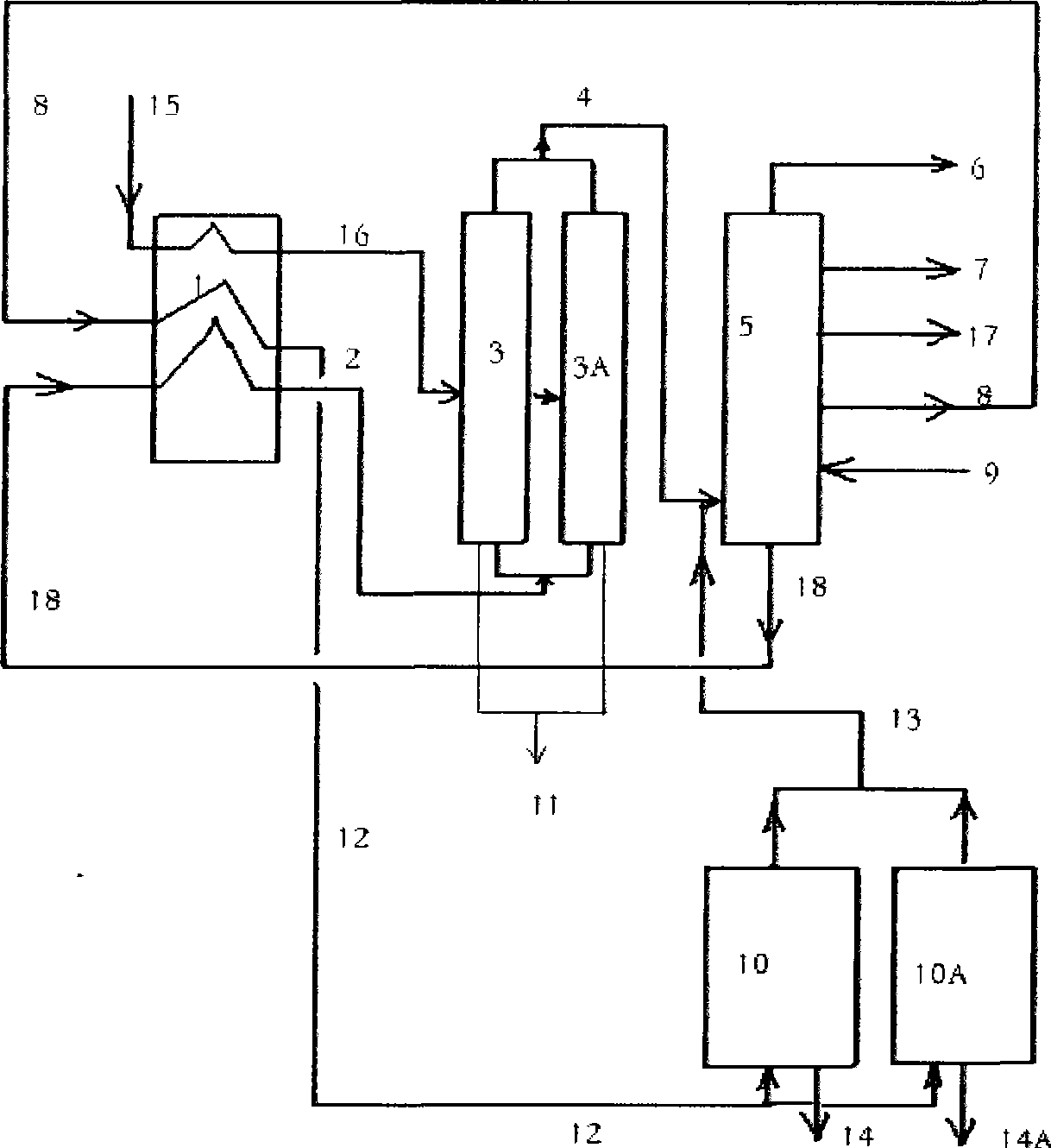

Method used

Image

Examples

Embodiment 1-5

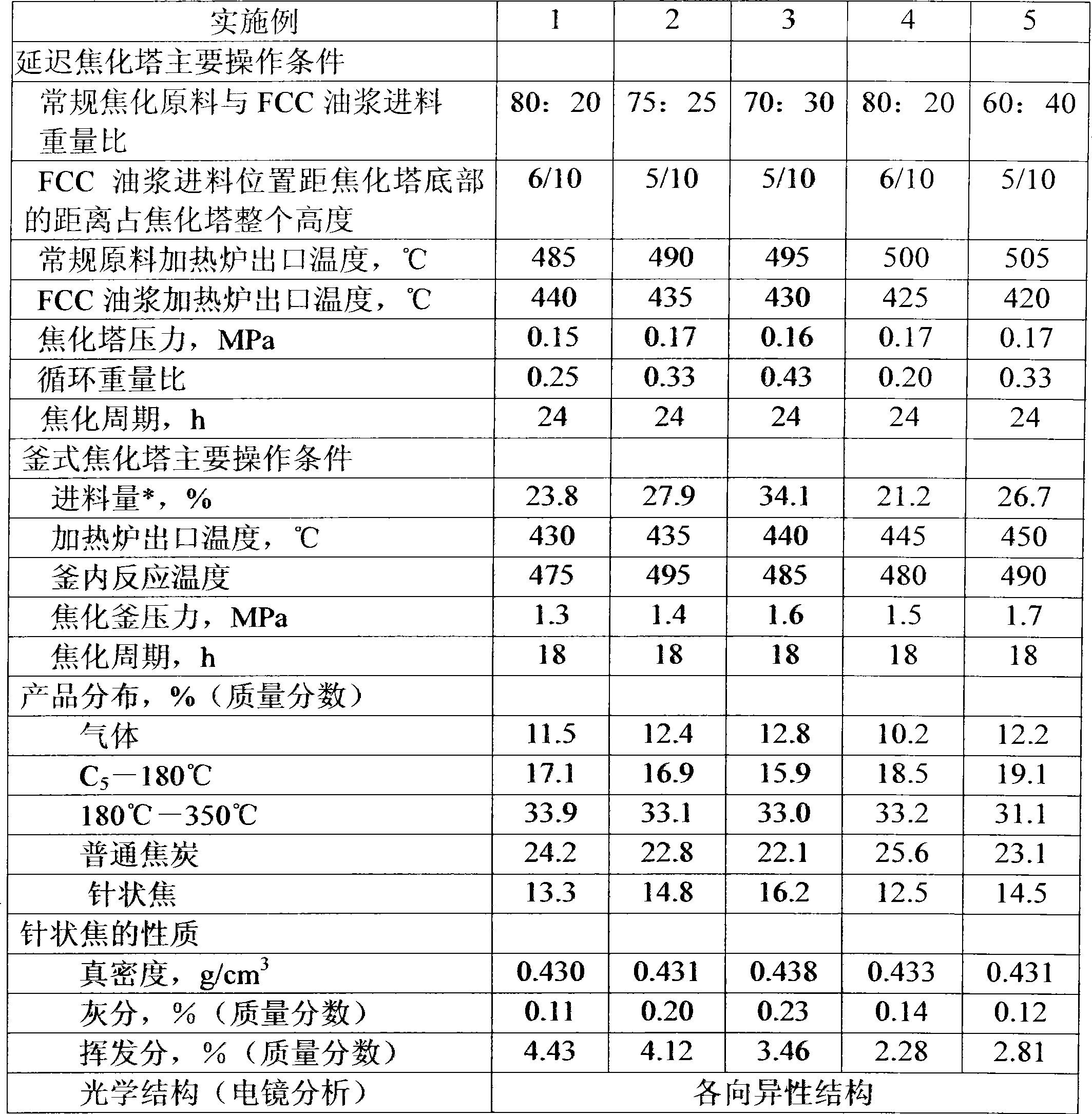

[0034] In the embodiment, all experiments use the same raw material oil, aiming to compare the effects under different operating conditions. The properties of conventional coking feedstock oil and FCC slurry used in the experiment are shown in Table 1, and the experimental conditions and results are shown in Table 2.

[0035] Table 1 The properties of the feedstock oil used in the examples

[0036] raw material FCC slurry Conventional Coker Raw Oil Density(20℃) / kg·m -3 1.0058 0.998 Viscosity(100℃) / mm 2 ·s 1 10.00 700 Freezing point / ℃ 34 50 Carbon residue, % (mass fraction) 7.10 16.2 Ash content, % (mass fraction) 0.372 0.06 S, % (mass fraction) 0.53 0.55 N / μg·g -1 4678 8841 C,% 88.44 87.36 H, % (mass fraction) 8.90 11.21 Four components, % (mass fraction)

Saturation 32.1 24.5 Aroma 54.2 28.9 colloid 13.2 39.7 Asphaltenes 0.5 6.9 Metal composition / μg·g -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com