Rare earth iron-doped transparent oxygen fluorine germanate microcrystalline glass and preparation method thereof

A technology of oxyfluorogermanate and glass-ceramic, applied in the field of glass-ceramic and its preparation, can solve the problems of limited glass-forming ability, environmentally harmful transparent oxy-fluorogermanate glass-ceramic, poor chemical stability, and the like, Achieve the effect of improving luminous intensity and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Weigh 50g of raw materials, and weigh the raw materials according to the molar percentages of each component in the matrix glass, and the molar percentages of each component in the matrix glass are: 48%GeO 2 , 17% Al 2 o 3 , 3% Ga 2 o 3 , 32%CaF 2 , the raw materials are the corresponding oxides, carbonates and fluorides of analytical purity and above. Mix the weighed 50g of raw materials evenly, place them in a platinum crucible, cover the surface, heat and melt in a silicon carbide rod circuit at 1300-1350°C, keep the temperature for 1.5h, and pour the molten material on a preheated stainless steel template , then enter the muffle furnace for annealing, the annealing temperature is 550°C, keep warm for 2 hours and then cool down with the furnace to obtain colorless transparent glass.

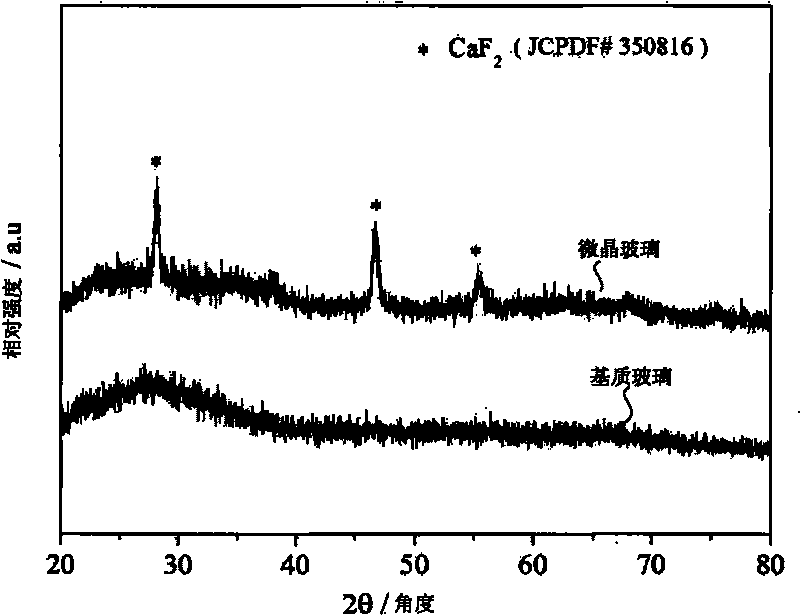

[0016] Differential thermal analysis (DTA) test is carried out on the matrix glass, and the transition temperature T of the glass is g is 578°C, the first crystalliz...

Embodiment 2

[0017] Embodiment 2: Weigh 50g of raw material, and weigh the raw material according to the molar percentage of each component in the matrix glass, and the molar percentage of each component in the matrix glass is respectively: 48%GeO 2 , 17% Al 2 o 3 , 3% Ga 2 o 3 , 2% LiF, 28% CaF 2 , 2% ErF 3 , wherein the raw materials are the corresponding oxides, carbonates and fluorides of analytical purity and above. Mix 50g of the weighed raw materials evenly, place them in a platinum crucible, cover the surface, heat and melt in a silicon carbide rod circuit at 1350-1380°C, keep it warm for 1.5 hours, and pour it on a preheated stainless steel template, then Enter the muffle furnace for annealing. The annealing temperature is 530°C, and after 2 hours of heat preservation, it is cooled with the furnace to obtain pink transparent glass.

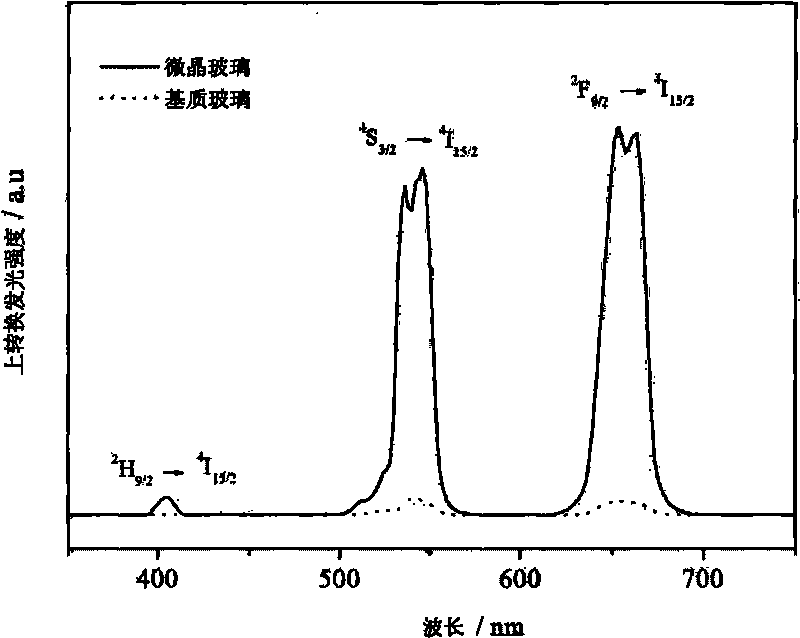

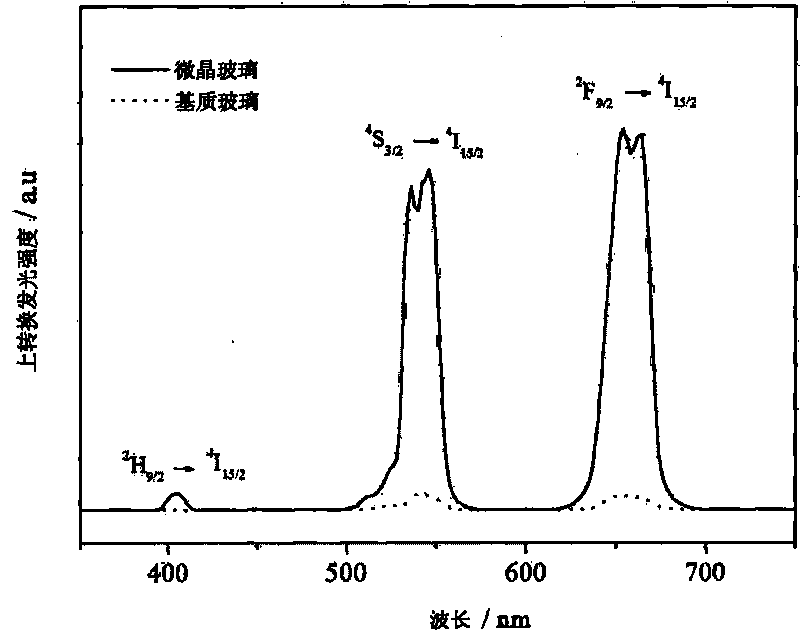

[0018] Differential thermal analysis (DTA) shows the transition temperature T of the matrix glass g is 572°C, the first crystallization peak ...

Embodiment 3

[0019] Example 3: The preparation method of the matrix glass in this example is basically the same as in Example 1, the difference is the components of the matrix glass, and the molar percentage of each component in the matrix glass in this example is: 38 %GeO 2 , 10% Al 2 o 3 , 5% Ga 2 o 3 , 1% LiF, 2% NaF, 40% CaF 2 , 4% PrF 3 , and then melted according to the method in Example 1, a light brown transparent matrix glass sample can be obtained.

[0020] According to the results of the differential thermal test, the heat treatment temperature for microcrystallization is selected to be 610-630° C., and the holding time is 64 hours to obtain a transparent glass-ceramic sample. Under the excitation of 1016nm Ti:Sapphire laser, the fluorescence of 1300nm was observed in the glass-ceramic sample, but no signal was observed in the matrix glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transition temperature | aaaaa | aaaaa |

| Fwhm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com