Material for purifying arsenate and chromate in drinking water and preparation method and application thereof

A medium arsenate and chromate technology, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of complex preparation process, limitation, and high cost, and achieve large adsorption capacity and low production cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

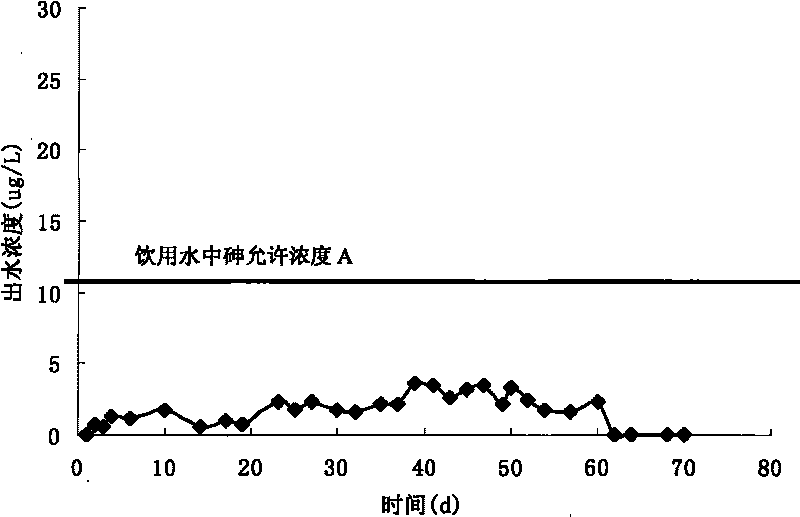

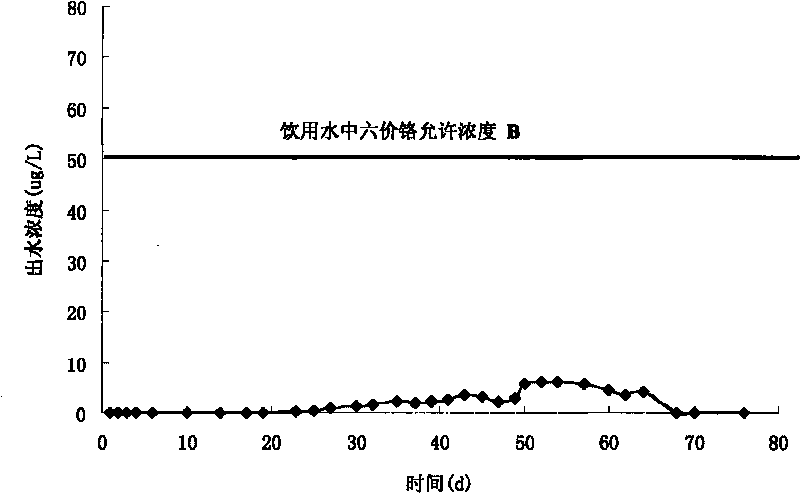

Embodiment 1

[0029] Select dense massive pyrrhotite ore from metal sulfide mines, wherein the content of pyrrhotite is not less than 90%, crush and sieve the pyrrhotite ore, and take the difference in particle size between 0.1 and 1.0mm Fill the filter column with granular particles, prepare simulated arsenic-containing and chromium-containing groundwater with tap water containing 1mg / L arsenic and 0.5mg / L chromium, and upflow the prepared arsenic-containing and chromium-containing water into the filter column, the hydraulic retention time For 1 hour, take out the filtered water regularly to detect the content of arsenic and chromium with atomic fluorescence and spectrophotometer respectively. After 70 days of filtering operation, the concentration of arsenic in the effluent is still lower than the standard A of the national drinking water on the content of arsenic, such as figure 1 shown; and the concentration of chromium in the effluent is still lower than the standard B for chromium cont...

Embodiment 2

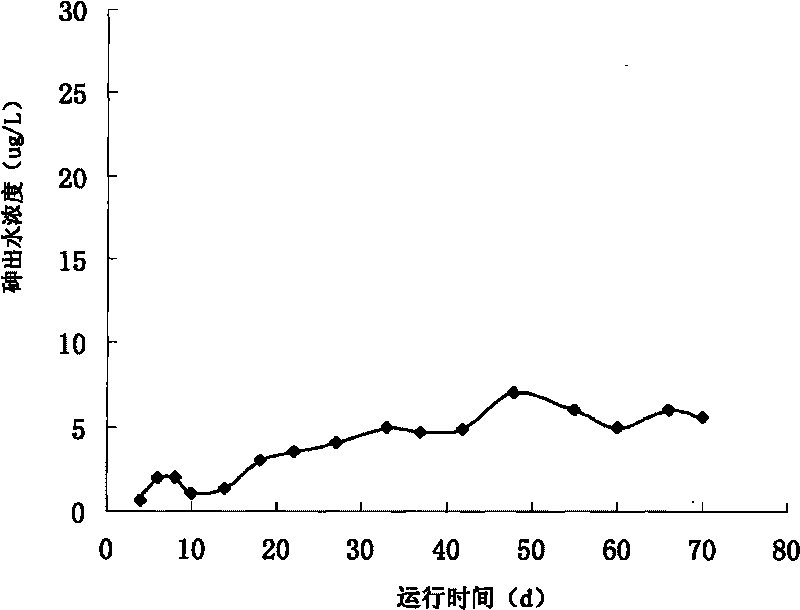

[0031] Select dense massive pyrite ore from pyrite mines, where the content of pyrite is not less than 90%, crush and screen the pyrite ore, and take different particle sizes between 0.1 and 1.0mm Particles, 10 grams of particles are filled in a tube furnace, calcined at 500°C for 3 hours under the protection of nitrogen, and cooled to room temperature to obtain pyrrhotite particles prepared by calcining pyrite, and pyrrhotite particles prepared by calcining pyrite Fill the filter column with ore particles, and prepare simulated high-arsenic and chromium groundwater containing 1 mg / L arsenic and 0.5 mg / L chromium with tap water. The prepared water enters the filter column with an upflow, and the hydraulic retention time is 1 hour. The content of arsenic and chromium was detected by atomic fluorescence and spectrophotometer. After 70 days of filtration operation, the concentration of chromium and arsenic in the effluent was still lower than the national drinking water standard, ...

Embodiment 3

[0033]The pyrite concentrate powder is obtained by beneficiating metal sulfide mines, the particle size is less than 0.1mm, and the content of pyrite is not less than 90%. Add water glass according to the ratio of 3-10% by mass, prepare 2-4mm granules in a ball forming machine, fill the granules into a tube furnace, calcinate at 500°C for 3 hours under the protection of nitrogen, and cool to room temperature to obtain Pyrhotite particles prepared by calcining pyrite powder, and then the pyrrhotite particles prepared by calcining pyrite powder were packed into a filter column, and tap water was used to prepare simulated arsenic-containing, Chromium underground water, the prepared water enters the filter column with upflow, the hydraulic retention time is 1 hour, and the filtered water is taken regularly to detect the content of arsenic and chromium with atomic fluorescence and spectrophotometer respectively. After 70 days of filtration operation, the chromium and arsenic concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com