Hollow microsphere with superparamagetism Fe3O4 nanocrystallines and preparation method thereof

A superparamagnetic and nanocrystalline technology, which is applied in the field of hollow microspheres and its preparation, can solve the problems of complex and cumbersome process, low efficiency, and long time consumption, and achieve the effect of simple preparation method, good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

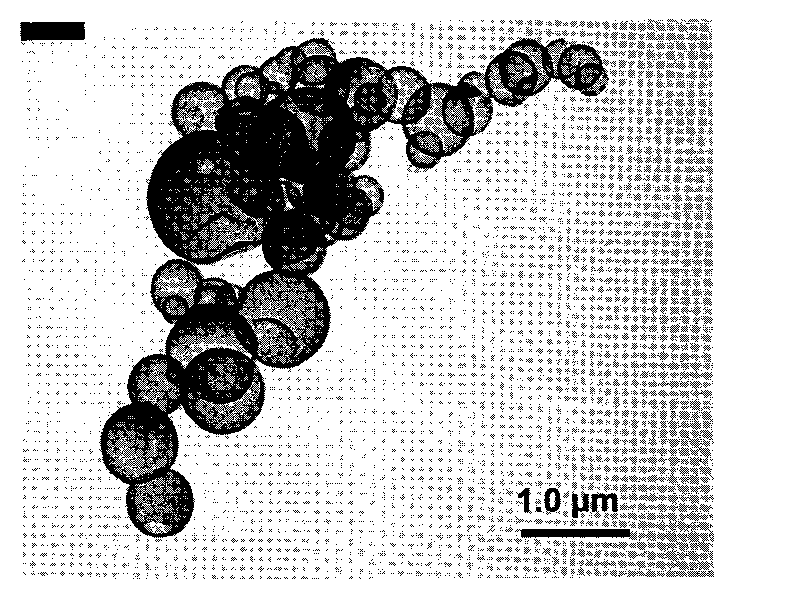

[0035] 12mL 0.5mol / L FeCl 3 Aqueous solution and 6mL 0.5mol / L FeSO 4 The aqueous solution was mixed, and nitrogen gas was passed for 30 minutes to remove oxygen; after the temperature was raised to 55 ° C, 10 mL of 3M NaOH aqueous solution was added dropwise, and then the temperature of the reaction system was raised to 65 ° C, and the reaction was kept for 1 hour; then the temperature was raised to 90 ° C, Keep warm for 30 minutes. After cooling to room temperature, the as-prepared Fe was separated using a magnet 3 o 4 Nanocrystals were washed sequentially with water and ethanol, and dried in vacuum.

[0036] 1g Fe 3 o 4 Disperse nanocrystals in 40mL ethanol, add 0.2mL dodecyltrimethylsilane DTS, pass nitrogen gas for 30 minutes to remove oxygen, then reflux for 6 hours under nitrogen atmosphere; after cooling to room temperature, use magnet to separate nanocrystals, ethanol Washed 3 times and dried in vacuum to obtain DTS-modified Fe 3 o 4 Nanocrystalline, labeled Fe...

Embodiment 2

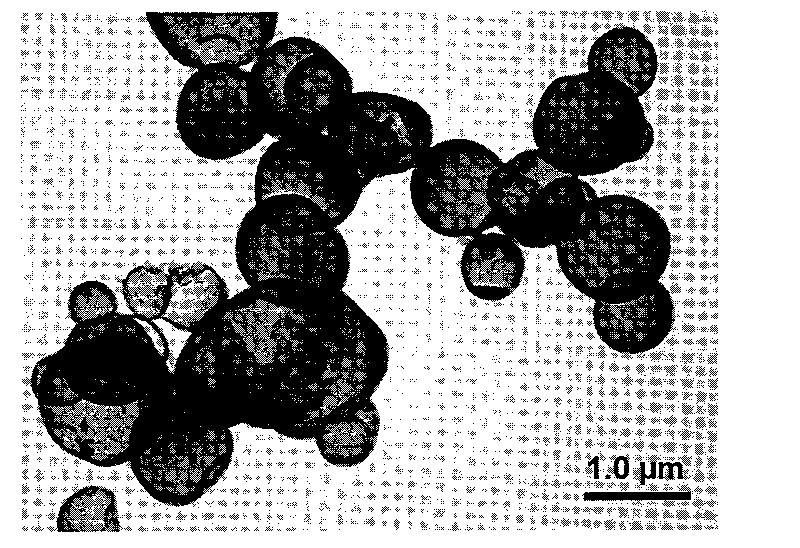

[0041] 1g Fe 3 o 4 Nanocrystals dispersed at a concentration of 1.0×10 -2 mol / L ethanol solution of phenyltrimethoxysilane (PTS), in N 2 Reflux for 2 h under protection, separate the nanocrystals after cooling to room temperature, wash with ethanol and dry to obtain PTS-modified Fe 3 o 4 Nanocrystalline, labeled Fe 3 o 4 -PTS.

[0042] In 4 mL of methyl methacrylate-styrene copolymer (P(MMA-co-St) with a concentration of 10 g / L in acetonitrile, 100 μL TEOS and 10 mg Fe 3 o 4 -HDTS mixed, sonicated for 10 minutes to make Fe 3 o 4 -PTS is fully dispersed to obtain solution A2. Pour this mixed solution into 16mL with a concentration of 2.0×10 -3 mol / L dodecyltrimethoxyammonium chloride aqueous solution B2. Add 0.4 mL of 28% ammonia water and react for 12 hours. Separation of embedded Fe by magnet 3 o 4 The nanocrystalline composite microspheres were washed with water and ethanol in turn, and dried at 50°C. The composite microspheres were soaked in 5mL of acetonitr...

Embodiment 3

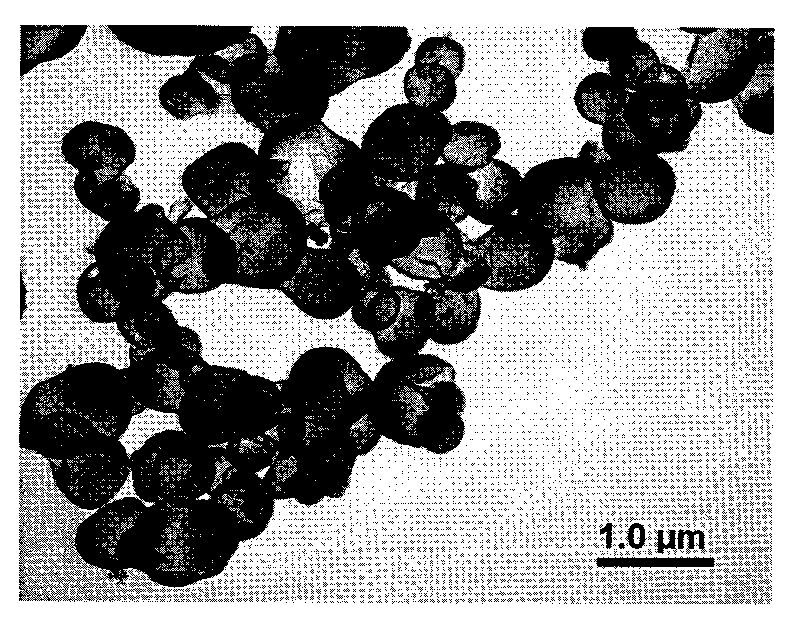

[0045] 1g Fe 3 o 4 Nanocrystals dispersed at a concentration of 1.0×10 -2 mol / L of octyltriethoxysilane (OTS) ethanol solution, in N 2 Under protection, reflux for 10 h, cool to room temperature, separate the nanocrystals, wash with ethanol and dry to obtain the hydrolyzed OTS-modified Fe 3 o 4 Nanocrystalline, labeled Fe 3 o 4 -OTS.

[0046] Add 100 μL TEOS and 20 mg Fe 3 o 4 -OTS mixed, sonicated for 15 minutes to make Fe 3 o 4 -OTS is fully dispersed to obtain solution A3. Pour this mixed solution into 16mL with a concentration of 2.0×10 -3 mol / L of octyltrimethoxyammonium bromide aqueous solution B3. Add 0.4 mL of 28% ammonia water and react for 12 hours. Separation of embedded Fe by magnet 3 o 4The nanocrystalline composite microspheres were washed with water and ethanol in turn, and dried at 50°C. The composite microspheres were soaked in 5mL THF and stirred for 6 hours to dissolve the PS and diffuse out of the microspheres, the magnets separated the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com