Solid medicinal composition of clopidogrel hydrogen sulfate

A kind of technology of clopidogrel hydrogen sulfate and composition, applied in the stable oral pharmaceutical composition field containing I crystal form clopidogrel hydrogen sulfate, achieves the effects of good reproducibility, stable quality, and overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

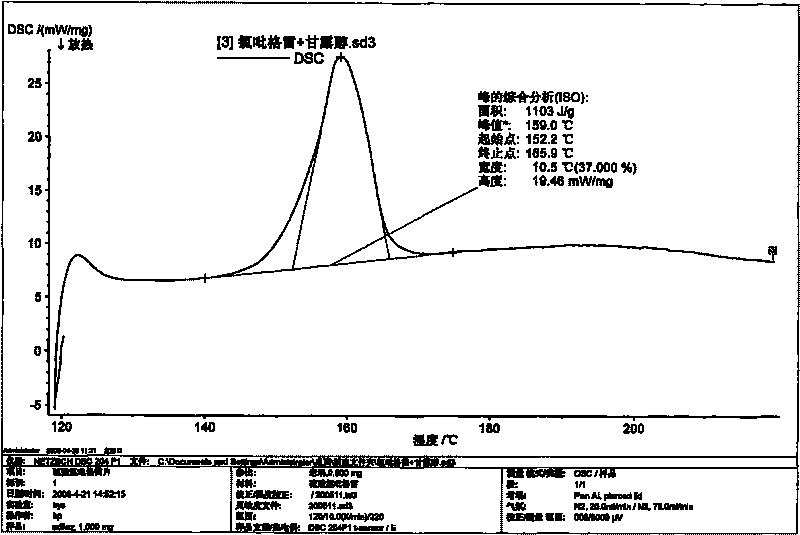

Image

Examples

Embodiment 1

[0040] Raw material name 1000 tablets dosage (g)

[0041] Form I Clopidogrel Bisulfate 97.9 (equivalent to Clopidogrel 75g)

[0042] PEG6000 3

[0043] Micronized silica gel 10

[0044] Microcrystalline Cellulose 135

[0045] Low-substituted hydroxypropyl cellulose 12.5

[0046] Gastric-soluble film coating premix appropriate amount

[0047] 1) Pass I crystalline form clopidogrel bisulfate through a 40-mesh sieve for later use.

[0048] 2) Pass the microcrystalline cellulose, low-substituted hydroxypropyl cellulose and micropowder silica gel through a 60-mesh sieve respectively, and dry at 105°C for 2 hours for later use.

[0049] 3) The polyethylene glycol 6000 is jet-pulverized into fine powder for later use.

[0050] 4) After mixing the prescription amount of crystalline form clopidogrel hydrogen sulfate, microcrystalline cellulose and low-substituted hydroxypropyl cellulose evenly, pass through a dry granulator, and granulate with a 20-mesh sieve.

[0051] 5) Pass t...

Embodiment 2

[0056] Raw material name 1000 tablets dosage (g)

[0057] Form I Clopidogrel Bisulfate 32.6 (equivalent to Clopidogrel 25g)

[0058] Polyethylene glycol 6000 150

[0059] Micronized silica gel 30

[0060] Pregelatinized starch 85

[0061] Low-substituted hydroxypropyl cellulose 22

[0062] Gastric-soluble film coating premix appropriate amount

[0063] 1) Pass I crystalline form clopidogrel bisulfate through an 80-mesh sieve for later use.

[0064] 2) Pass pregelatinized starch, low-substituted hydroxypropyl cellulose and micropowder silica gel through 80-mesh sieve respectively, and dry at 105°C for 2 hours for later use.

[0065] 3) Pass polyethylene glycol 6000 through a 60-mesh sieve for later use.

[0066] 4) Mix the prescription quantity I crystal form clopidogrel hydrogen sulfate, polyethylene glycol 6000, pregelatinized starch, low-substituted hydroxypropyl cellulose and 80% prescription quantity of micropowder silica gel evenly, pass through a dry granulator, an...

Embodiment 3

[0072] Raw material name 1000 tablets dosage (g)

[0073] Form I Clopidogrel Bisulfate 97.9 (equivalent to Clopidogrel 75g)

[0074] Polyethylene glycol 6000 2

[0075] Micronized silica gel 10

[0076] Microcrystalline Cellulose 150

[0077] Low-substituted hydroxypropyl cellulose 4

[0078]Gastric-soluble film coating premix appropriate amount

[0079] 1) Pass clopidogrel bisulfate through a 40-mesh sieve for later use.

[0080] 2) Pass the microcrystalline cellulose, low-substituted hydroxypropyl cellulose and micropowder silica gel through a 60-mesh sieve respectively, and dry at 105°C for 2 hours for later use.

[0081] 3) The polyethylene glycol 6000 is jet-pulverized for later use.

[0082] 4) Mix the prescription amount of clopidogrel hydrogen sulfate, microcrystalline cellulose, and low-substituted hydroxypropyl cellulose evenly, pass through a dry granulator, and granulate with a 20-mesh sieve.

[0083] 5) Pass the dry granules through a 18-mesh sieve for gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com