Adhesion-free automatic vermicelli production line and production process thereof

A production line and fan technology, applied in the field of conveyor belts, can solve the problems of occupying workshop space, increasing process steps, and consuming more time, and achieving the effect of saving occupied area, reducing production processes, and reducing production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] Such as figure 1 The non-adhesive automatic vermicelli production line shown includes extruder 1, pre-dryer 2, transition conveyor 3, cutting conveyor 4, pre-drying and setting machine 5, dryer 6, and air cooler 7 according to material transmission And packaging conveyor 8.

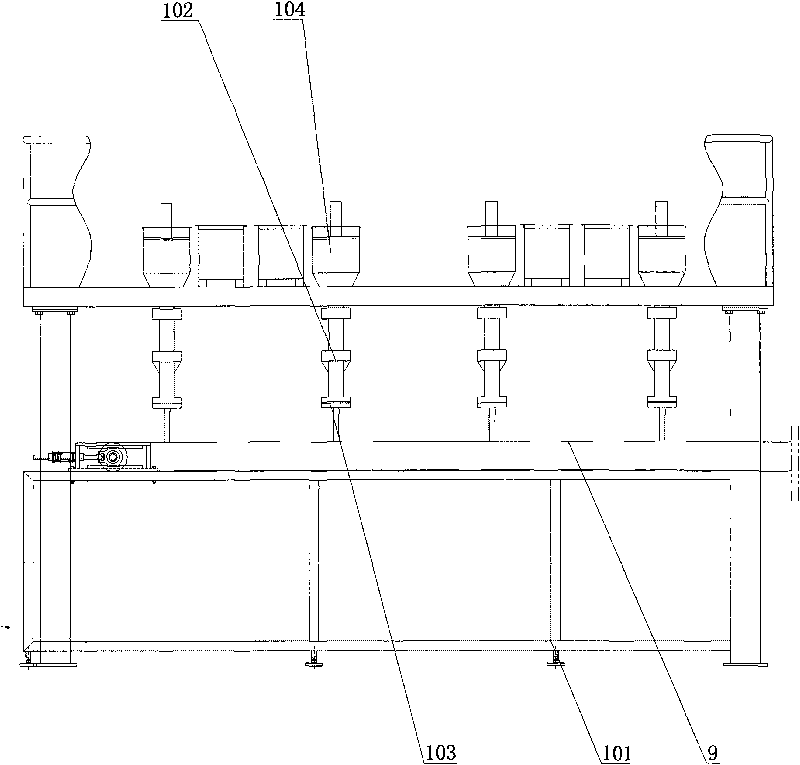

[0038] Such as image 3 As shown, the wire extrusion machine 1 is composed of a wire extrusion frame 101 and a wire extrusion device. The wire extrusion device includes a wire extrusion cylinder 102, a wire extrusion head 103 connected with the wire outlet end of the extrusion cylinder 102, and is located on the extrusion wire The extruding screw (not shown) in the barrel 102, the hopper 104 connected to the powder inlet end of the extruding barrel 102, the extruding motor (not shown) connected to the extruding screw; the extruding frame 101 The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com