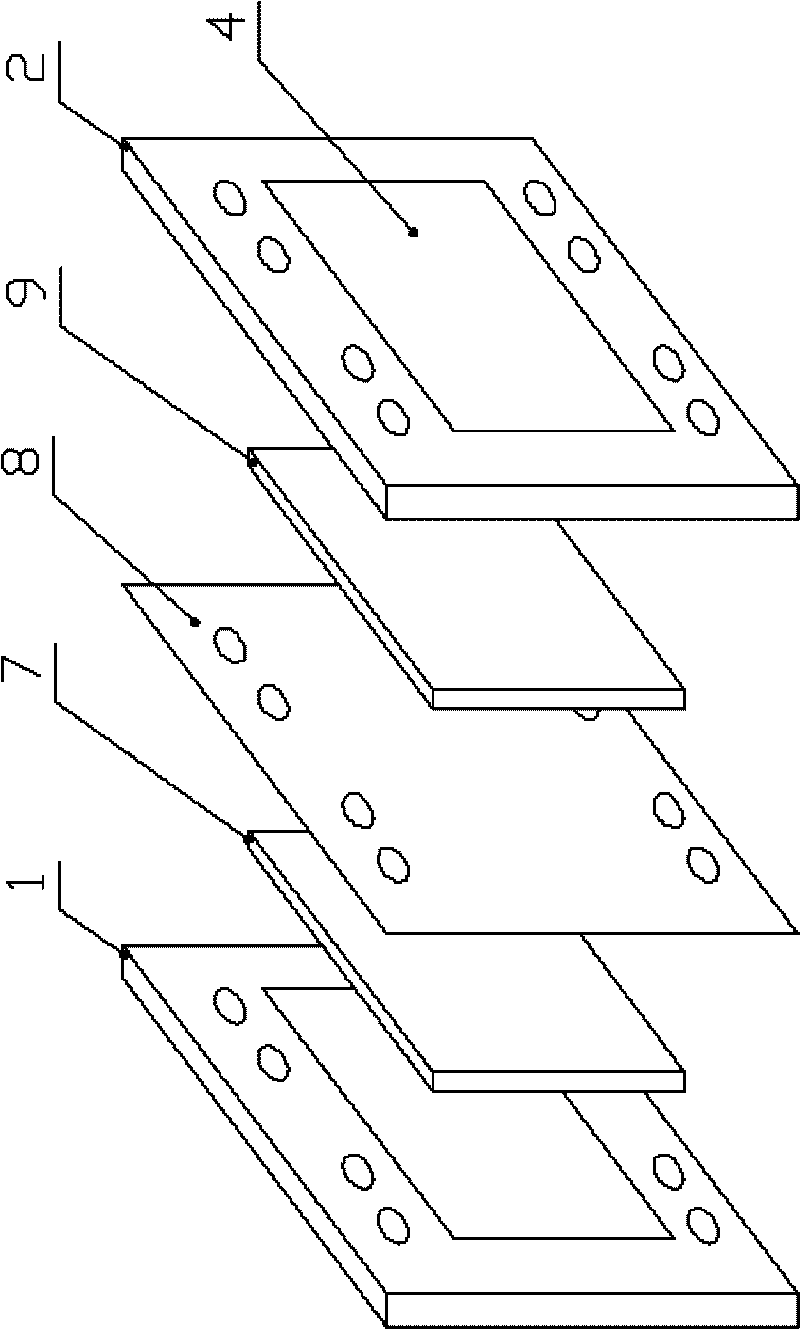

Pile structure of redox flow battery

A technology of liquid flow batteries and battery stacks, which is applied to battery electrodes, fuel cell components, fuel cells, etc., can solve the problems of polarization voltage hydrogen and oxygen evolution, slow diffusion, electrode reaction dead zone, etc., to increase the interface Effect of area, flow uniformity, speed promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The electrode active material of the vanadium redox battery is vanadium-containing sulfuric acid solution, and the positive electrode electrolyte is V-containing 4+ / V 5+ The sulfuric acid solution of the redox pair, the negative electrode electrolyte is containing V 2+ / V 3+ Redox couple in sulfuric acid solution.

[0018] The reaction principle of vanadium battery is as follows:

[0019] positive electrode:

[0020] negative electrode:

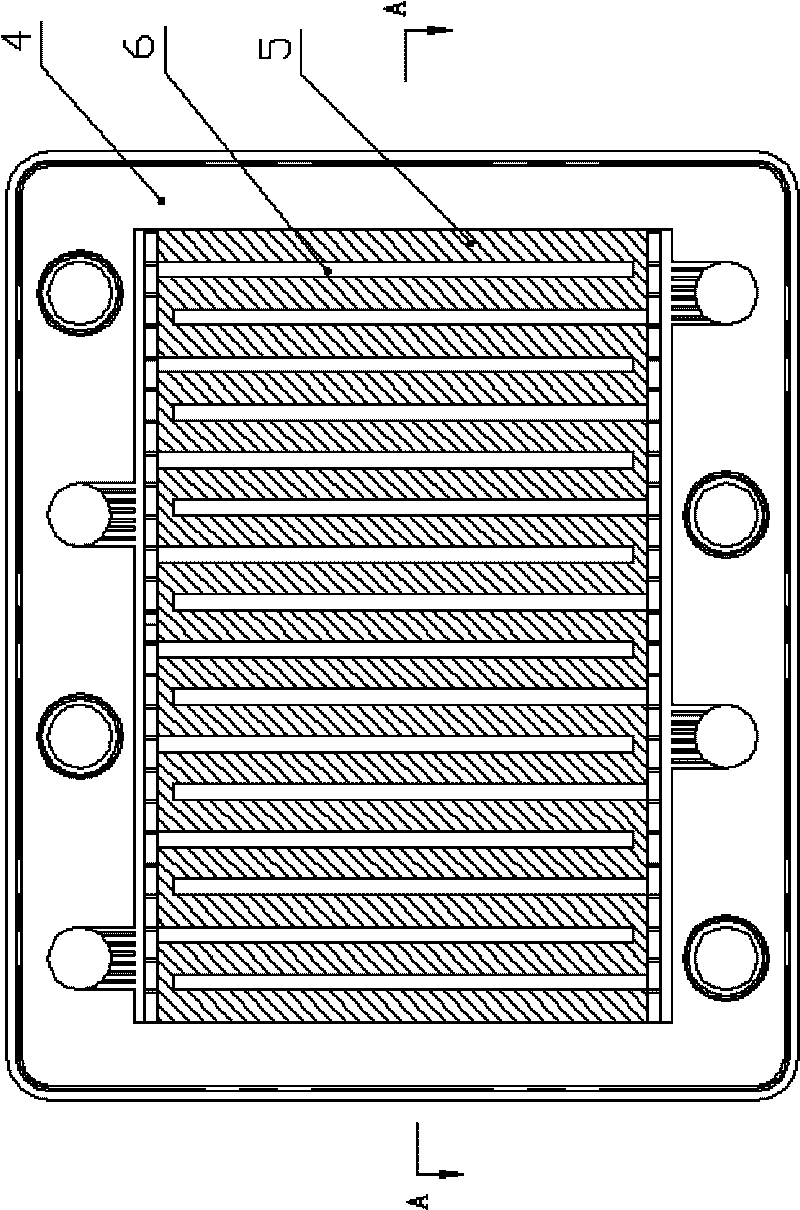

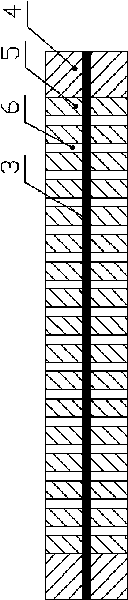

[0021] Design and assemble two batteries, the current collector plate is a 1mm conductive electrode plate, the effective electrode area is 500*300mm, a set of composite flow field plates (interdigitated flow field), the actual reaction electrode area after removing the flow field plate is 1250cm 2 , and the other group is a plate electrode without a flow field plate. The positive and negative electrolytes are 1.6mol / L V in 1000ml 4+ +3mol / L H 2 SO 4 and 1.6mol / L V in 1000ml 3+ +3mol / L H 2 SO 4 solution, the porous ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com