Magnesite micro powder-assisting flame-resistant expanded halogen-free flame-resistant electronic wire-coated material and preparation method thereof

A technology of auxiliary flame retardant and auxiliary flame retardant, applied in the field of wire material, can solve the problems of low physical properties, high price, poor water resistance, etc., and achieve the effect of excellent physical properties and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

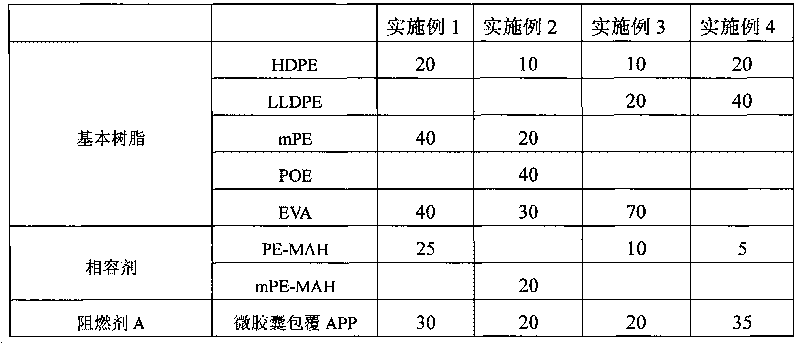

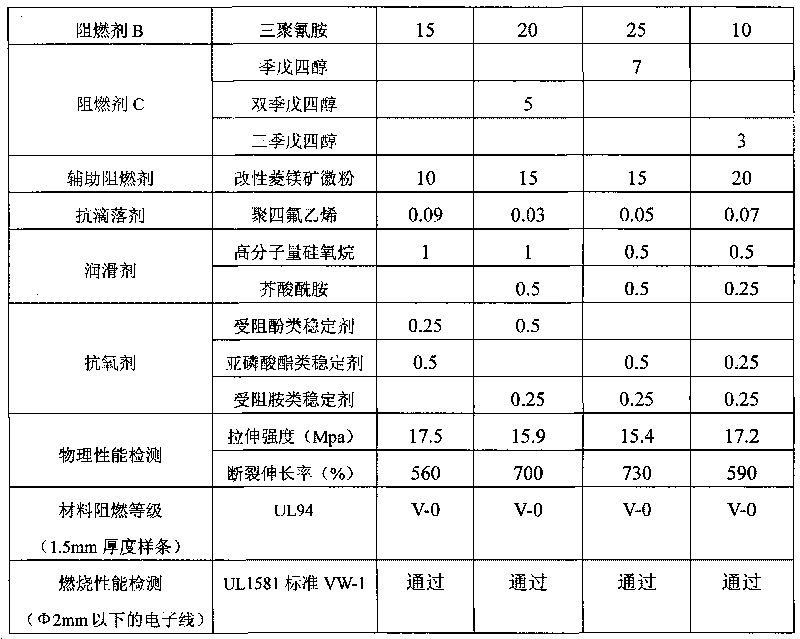

[0021] Magnesite micropowder auxiliary flame retardant expanded halogen-free flame retardant electronic wire outer quilt contains basic resin, compatibilizer, flame retardant, auxiliary flame retardant, lubricant, antioxidant; the basic resin is high-density poly One or more mixtures of ethylene, low density linear polyethylene, metallocene polyethylene, POE, EVA; the compatibilizer is one or more mixtures of PE-g-MAH and mPE-g-MAH ; The anti-drip agent is polytetrafluoroethylene, the antioxidant is at least one of hindered phenols, phosphites, and hindered amine antioxidants, and the flame retardant A is a phenolic resin The microcapsules of the capsule wall are coated with ammonium polyphosphate, the flame retardant B is melamine, and the flame retardant C is one or more mixtures of pentaerythritol, dipentaerythritol, and tripentaerythritol; the auxiliary flame retardant The agent is a modified micron-level magnesite powder, and the fractions of the described raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com