Method for preparing tissue engineering scaffold by pore forming of directional soluble fibres

A tissue engineering scaffold and fiber technology, applied in the field of medical materials, can solve the problems of high obturator rate, poor connection, and difficult removal of NaCl particles, etc., and achieve the effect of low obturator rate and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the tissue engineering scaffold provided by the invention is:

[0032] a) Making sucrose into sucrose fiber, the sucrose fiber can be spun with a rotary disk spinning device.

[0033] b) dissolving the biodegradable polymer in a solvent to prepare a polymer solution, wherein the weight ratio of the biodegradable polymer to the sucrose fiber is preferably 1:1 to 1:8, in the polymer solution, The weight-volume ratio of the biodegradable polymer to the solvent is preferably 1%-6%, and the unit of the weight-volume ratio is (g / mL)×100% known in the art.

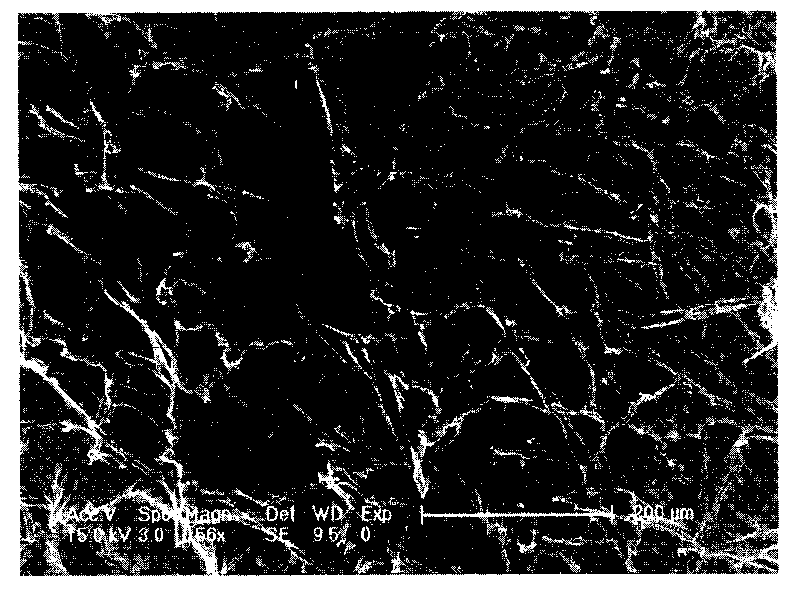

[0034] Preferably, NaCl particles can also be added to the polymer solution, the weight volume ratio of NaCl particles to the polymer solution is preferably 1%-6%, and the particle size of the NaCl particles is preferably 100 μm-450 μm. The larger particle size of NaCl particles can create larger pores to facilitate the exchange of nutrients and metabolites by cells.

[0035] Biodegradable polym...

Embodiment 1

[0043] The polymer solution is prepared, the biodegradable polymer is selected from PLA, the solvent is selected from chloroform, and the weight of PLA accounts for 6% of the volume of chloroform.

[0044] After the sucrose is made into sucrose fibers, the sucrose fibers are spread in the moulds, and the weight ratio of PLA to sucrose fibers is 1:1. Negative pressure is applied to make the polymer solution saturate the sucrose fiber to prepare the composite solution.

[0045] The obtained composite solution was placed in a fume hood to allow the solvent to evaporate naturally, and the composite of PLA and sucrose fiber was obtained after drying.

[0046] The composite of PLA and sucrose fiber is placed in ultrapure water, and the sucrose is separated out to obtain a tissue engineering scaffold.

Embodiment 2

[0048] The polymer solution is prepared, the biodegradable polymer is selected from PLGA, the solvent is selected from acetone, and the weight of PLGA accounts for 1% of the volume of the acetone.

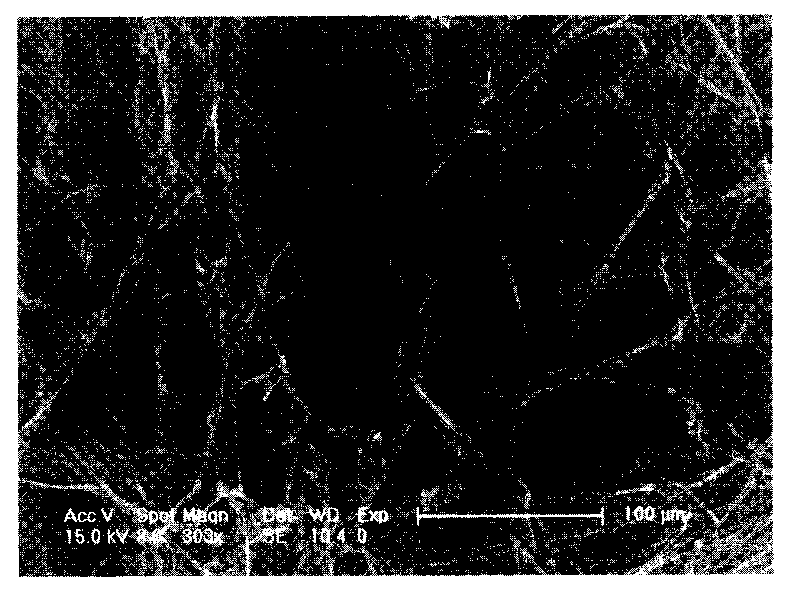

[0049] After the sucrose is made into sucrose fibers, the sucrose fibers are spread in the mold according to the longitudinal arrangement, and the weight ratio of PLGA to sucrose fibers is 1:8. Negative pressure is applied to make the polymer solution saturate the sucrose fiber to prepare the composite solution.

[0050] The obtained composite solution was placed in a fume hood to allow the solvent to evaporate naturally, and the composite of PLGA and sucrose fiber was obtained after drying.

[0051] The PLGA and sucrose fiber composite is placed in ultrapure water, and the sucrose is separated out to obtain a tissue engineering scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com