Method for refining LA141 magnesium-lithium alloy grains

A magnesium-lithium alloy and crystal grain technology is applied in the field of adding Al-5Ti-1B master alloy to refine magnesium-lithium alloy crystal grains, which can solve the problems of high cost and low value for industrialization and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

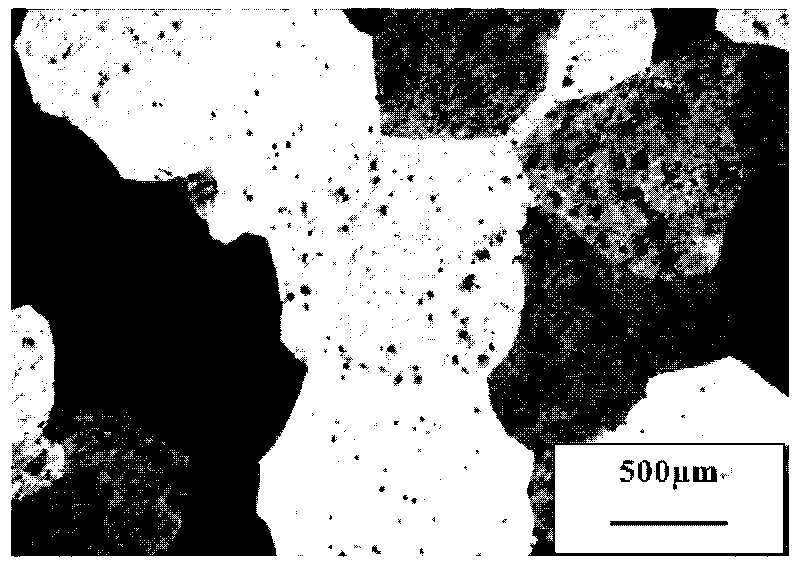

[0025] Adopt the following formula (mass percentage): Mg: 83.95%; Li: 14.0%; Al: 1.25%; Al-5Ti-1B: 0.50%; wherein Mn, Fe, Si, Ni, Cu, Na are less than 0.30%, and the melting It is carried out in a vacuum induction melting furnace, and the above-mentioned various components are put into a stainless steel crucible. Before smelting, evacuate the furnace to a vacuum state, then introduce argon, and then start smelting. After the alloy is completely melted, keep it at 700°C for 15 minutes. After the alloy is completely solidified, take out the crucible to obtain the cast alloy. The whole melting process is under the protection of argon.

[0026] The grain size of the obtained magnesium-lithium alloy was measured by the intercept method, and the average grain size was 800 μm.

Embodiment 2

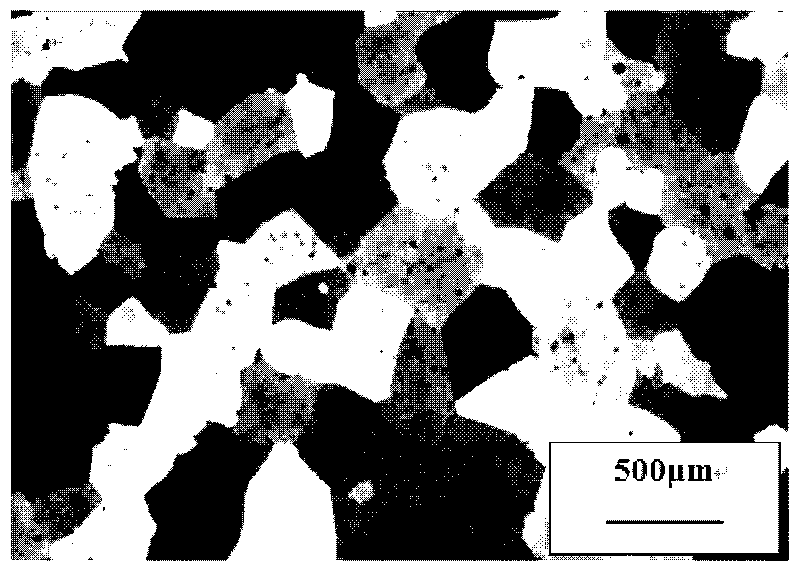

[0028] The following formula (mass percentage) Mg: 83.45%; Li: 14.0%; Al: 1.25%; Al-5Ti-1B: 1.0%; Mn, Fe, Si, Ni, Cu, Na less than 0.30%, smelting in vacuum Carried out in an induction melting furnace, the various components are placed in stainless steel crucibles. Before smelting, evacuate the furnace to a vacuum state, then introduce argon, and then start smelting. After the alloy is completely melted, keep it at 700°C for 15 minutes. After the alloy is completely solidified, take out the crucible to obtain the cast alloy. The whole melting process is under the protection of argon.

[0029] The grain size of the obtained magnesium-lithium alloy was measured by the intercept method, and the average grain size was 750 μm.

Embodiment 3

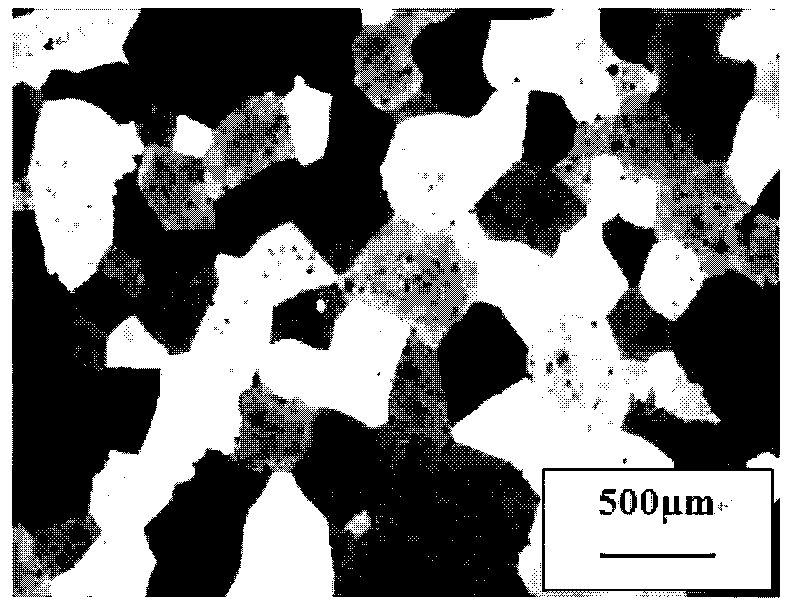

[0031] Adopt the following formula (mass percentage): Mg: 83.20%; Li: 14.0%; Al: 1.25%; Al-5Ti-1B: 1.25%; Mn, Fe, Si, Ni, Cu, Na are less than 0.30%, melting in vacuum It is carried out in an induction melting furnace, and the above-mentioned various components are put into a stainless steel crucible. Before smelting, evacuate the furnace to a vacuum state, then introduce argon, and then start smelting. After the alloy is completely melted, keep it at 700°C for 15 minutes. After the alloy is completely solidified, take out the crucible to obtain the cast alloy. The whole melting process is under the protection of argon.

[0032] The grain size of the obtained magnesium-lithium alloy was measured by the intercept method, and the average grain size was 550 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com