Method for improving dispersity of insoluble sulfur

A dispersive and sulphur technology, applied in grain processing and other directions, can solve the problems of difficult implementation, poor conductivity, complex process, etc., and achieve the effect of improving production efficiency, excellent dispersibility and increasing investment.

Inactive Publication Date: 2010-05-26

JIANGSU HONGTAI RUBBER AUX

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the poor electrical conductivity of IS, when its particle size is small, the specific surface area is large, so static electricity is easily generated during the preparation of IS and the rubber mixing process in tire factories. IS has poor dispersion in the rubber compound and accumulates into small particles. Soybean-like particles lead to waste of rubber compound and tires. Therefore, improving the dispersion of IS is an urgent problem to be solved

FLEXSYS company in the United States adopts the powder surface coating rubber treatment method to improve IS dispersion, but the process is complicated, the efficiency is low, and the cost is high, so it is difficult to implement in China

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

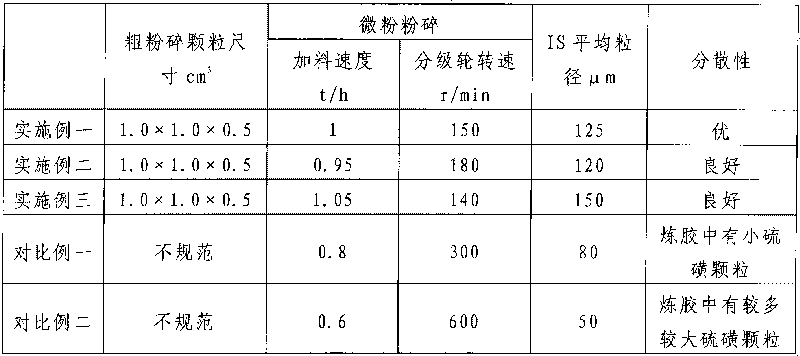

[0007] The present invention is further illustrated below by examples and comparative examples.

[0008]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for improving the dispersity of insoluble sulfur (IS), which comprises the following steps of: firstly, crushing a solidified and dried IS-60 blocky material into particles in a boulder crusher; and secondly, crushing the particles into powder with the particle size of 120 to 150 mu m in a micro powder crusher, wherein in the micro powder crushing process, the feed rate is 0.95 to 1.05 t / h, and the grading wheel speed is 140 to 180 r / min. The method improves the conventional crushing process, performs adjustment and optimized matching on the feed rate and the grading wheel speed, controls the IS particle size to be 120 to 150 mu m, breaks through the traditional mistaken idea that the particle size of less than 150 mum is qualified, and ensures that the prepared IS powder has no electrostatic accumulation during production, the dispersity is good, and the product is favorable for well-known tire companies; besides, the method is simple and convenient to operate, needs no investment increase, and is suitable for industrial production.

Description

technical field [0001] The invention relates to a method for improving product dispersibility in the production of insoluble sulfur. Background technique [0002] Insoluble sulfur is also called homogeneous polymeric sulfur, or IS for short. It is currently widely used as a vulcanizing agent for radial tires. The production of IS is usually to polymerize molten liquid sulfur by high temperature vaporization, solidify and dry into IS-60 block material (IS-60 is polymerized sulfur containing about 40% soluble sulfur), and then crush it into IS-60 powder, and then Then extract it into IS-90 powder. Among them, the crushing process directly affects the dispersibility of IS products, and affects the quality of rubber materials and tires. In the existing production process, the bulk material is made into powder through coarse crushing and micro-powdering. It is generally believed that the particle size of the powder should be controlled below 100 μm. And the rotating speed of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C23/00

Inventor 张志诚

Owner JIANGSU HONGTAI RUBBER AUX

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com