Method for producing insoluble sulfur by using liquid phase method

A liquid phase method, sulfur technology, applied in the preparation/purification of sulfur, etc., can solve the problems of poor thermal stability and dispersion, high production cost, high polymerization conversion rate, etc., to improve melting point and dispersion, and ensure high thermal stability , the effect of high insoluble sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

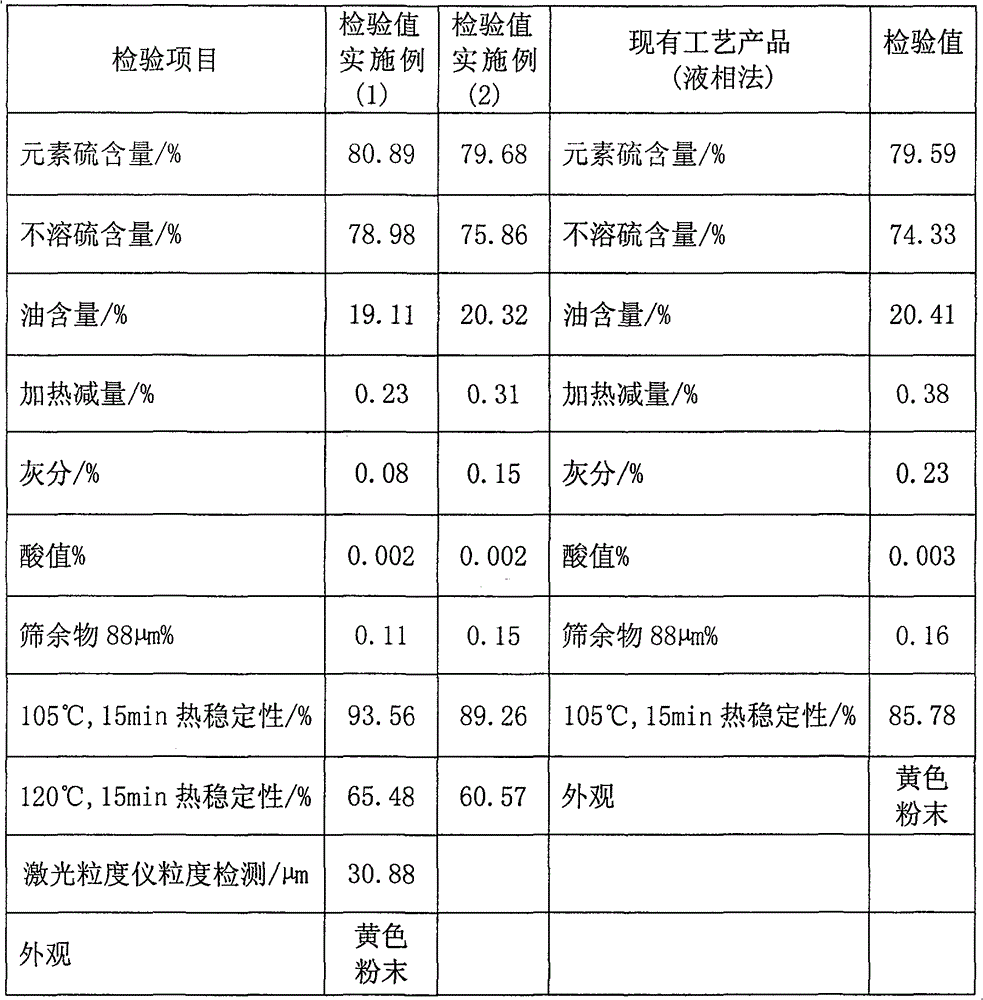

Examples

Embodiment 1

[0018] 1) Melting aging: Add industrial sulfur with a purity ≥ 99.9% to a melting kettle with a capacity of 8T and melt it. When the temperature in the kettle reaches 340-350°C, keep it at a constant temperature for 30 minutes, and then spray FeCl 3 +HNO 3 +H 2 O quenching liquid for quenching treatment, FeCl 3 with HNO 3 The weight percentages in the quenching liquid are 2% and 0.4% respectively, and then dried at 70-75°C for 8-9 hours to obtain 60 pieces with a weight percentage of insoluble sulfur of 40% and a weight content of soluble sulfur of 60%;

[0019] 2) Extraction: put 60 aged strips in the extraction tank with pure CS 2 Solvent extraction 3 times, each time 50min, so that the weight percentage of insoluble sulfur after extraction is ≥ 95%, that is, 90 strips with insoluble sulfur content of more than 90% and soluble sulfur content of about 10% are obtained. The used CS2 solvent can be recycling through distillation;

[0020] 3) Stabilization treatment: 0.75 k...

Embodiment 2

[0025] 1) Melting aging: Add industrial sulfur with a purity ≥ 99.9% to a melting kettle with a capacity of 8T and melt it. When the temperature in the kettle reaches 340-350°C, keep it at a constant temperature for 30 minutes, and then spray FeCl 3 +HNO 3 +H 2 O quenching liquid for quenching treatment, FeCl 3 with HNO 3 The weight percentages in the quenching liquid are 2% and 0.4% respectively, and then dried at 70-75°C for 8-9 hours to obtain 60 pieces with a weight percentage of insoluble sulfur of 40% and a weight content of soluble sulfur of 60%;

[0026] 2) Extraction: put 60 aged strips in the extraction tank with pure CS 2 Solvent extraction 3 times, each time 40min, so that the weight percentage of insoluble sulfur after extraction is ≥ 95%, that is, 90 strips with an insoluble sulfur content of more than 90% and a soluble sulfur content of about 10% are obtained. The used CS2 solvent can be recycling through distillation;

[0027] 3) Stabilization treatment: 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com