Air wall sealing type double positive pressure purification workbench

A hermetically sealed, bench-top technology for chemical instruments and methods, laboratory benches/benches, enclosures or chambers, which can solve problems such as maintaining positive pressure, discharge to operators, large dust particles, etc. To achieve the effect of reducing dust particles and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

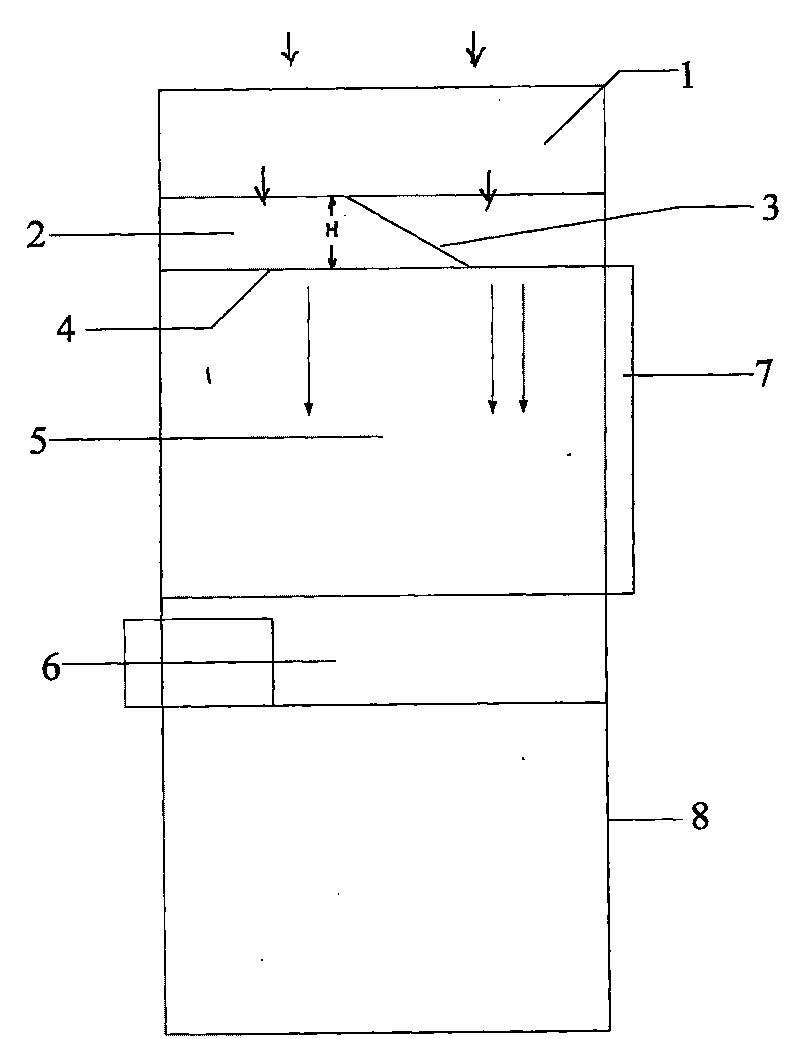

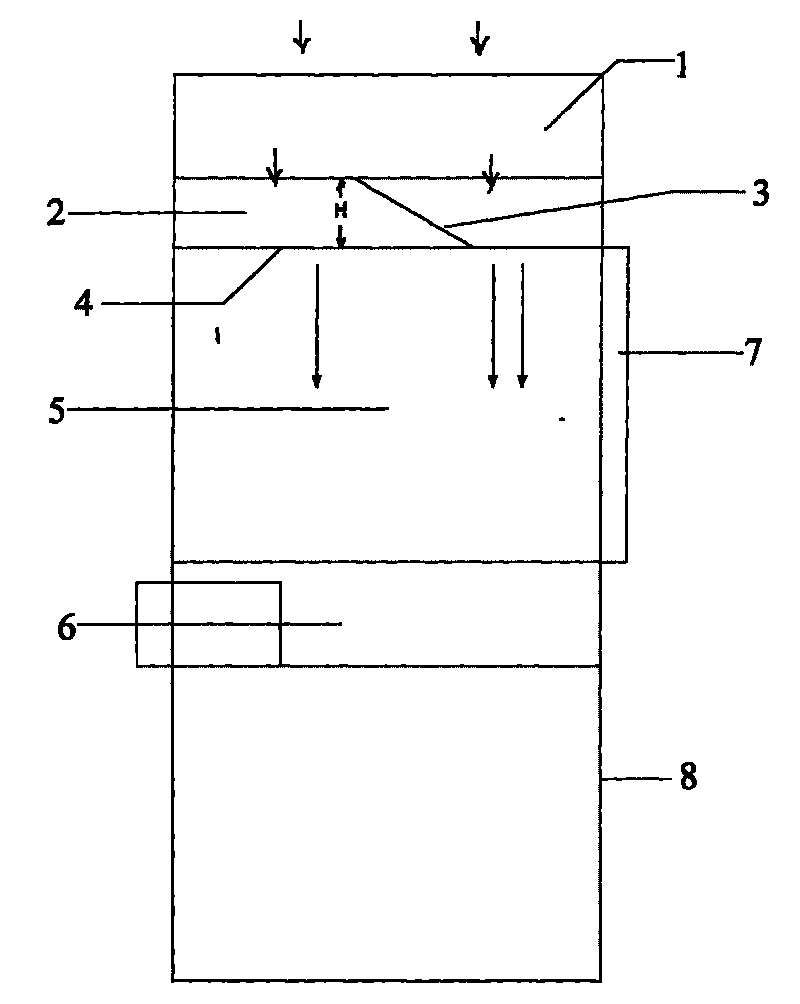

[0011] An air wall-sealed double positive pressure purification workbench, comprising an air intake system 1, a diversion and pressure division area 2 is set under the intake system, a diffuser plate 4 is located at the bottom of the diversion pressure division area, and a working chamber is arranged under the diffuser plate body 5, the working cavity communicates with the air extraction system 6, the height H of the diversion pressure division area is 40-60 mm, and the diversion pressure division plate 3 is set in the diversion pressure division area, and the diversion pressure division plate is arranged obliquely on the guide In the flow partial pressure area, the diversion partial pressure area is divided into two trapezoidal cross-section areas at the front and rear, and the trapezoidal cross-sectional area at the front (that is, near the operator side) is in the form of a large inlet end and a small air outlet end. , at the back (that is, on the side away from the operator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com