Metal oxide-loaded molecular sieve catalyst and preparation method thereof

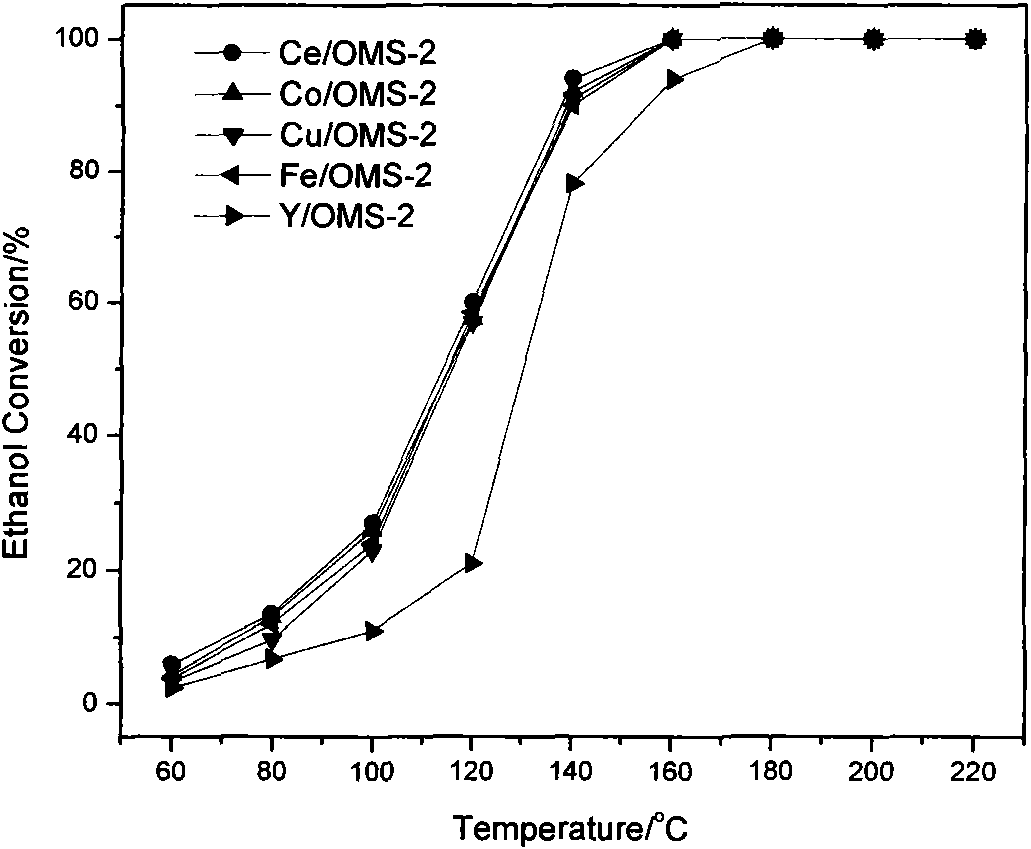

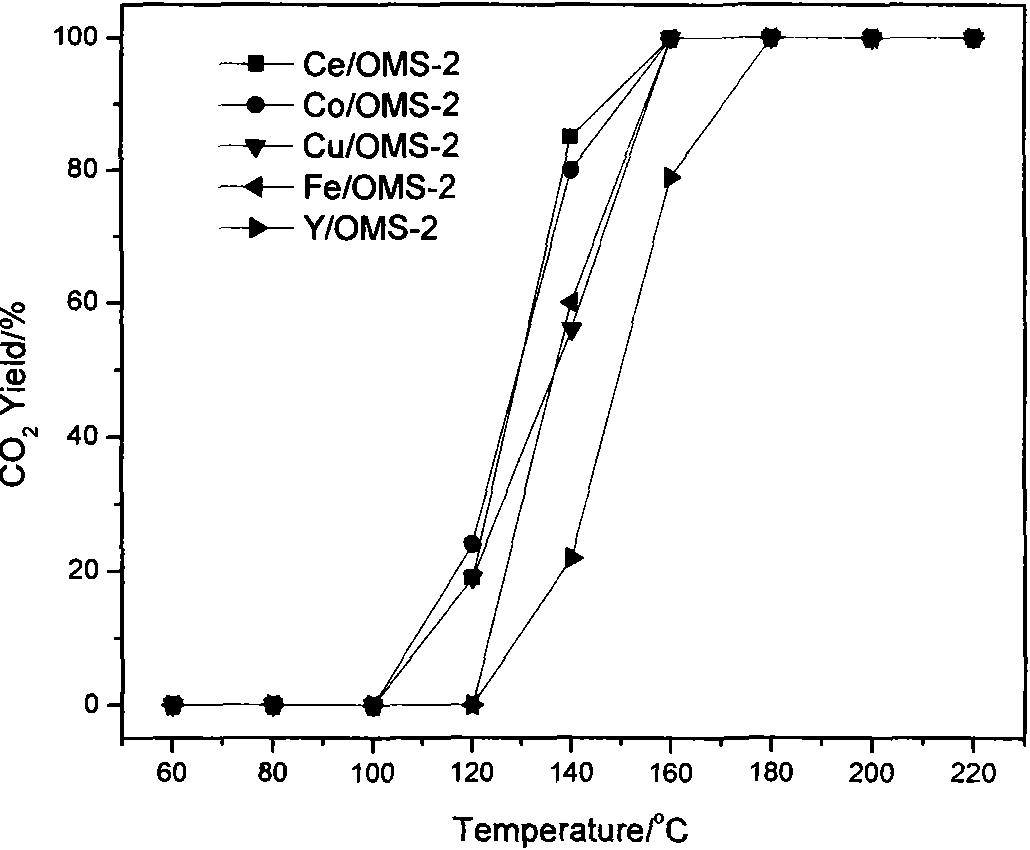

A technology of supporting metals and catalysts, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve the problems of poor oxidation effect of ethanol acetaldehyde and unsatisfactory purification effect, and achieve excellent low-temperature removal performance of ethanol acetaldehyde , Outstanding oxidation ability, good low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A molecular sieve catalyst loaded with metal oxides, comprising the following components:

[0025] Pure cryptopotassium manganese dioxide is the active component, accounting for 94% of the total mass of the catalyst, and the doped transition metal Ce component accounts for 6% of the total mass of the catalyst, and the active component passes through Mn 7+ and Mn 2+ The reaction generates, and the molar ratio of the two is 0.72.

[0026] A method for preparing a metal oxide-loaded molecular sieve catalyst, which is prepared by a reflux method, specifically comprises the following steps:

[0027] 1. Prepare 280mL of potassium permanganate solution with a concentration of 0.38mol / L, heat and stir at 56°C to form a solution;

[0028] 2. Configure 288mL of manganese acetate solution with a concentration of 0.54mol / L, heat and stir at 58°C to form a solution;

[0029] 3. Slowly add the solution obtained in step 1 into a 1000mL three-necked flask, heat in an oil bath at 108...

Embodiment 2

[0038] An octahedral manganese oxide molecular sieve catalyst comprises the following components:

[0039] Pure cryptopotassium manganese dioxide is the active component, accounting for 90% of the total mass of the catalyst, and the doped transition metal Co component accounts for 10% of the total mass of the catalyst, and the active component passes through Mn 7+ and Mn 2+ The reaction generates, and the molar ratio of the two is 0.72.

[0040] A method for preparing a metal oxide-loaded molecular sieve catalyst, which is prepared by a reflux method, specifically comprises the following steps:

[0041] 1. Prepare 150mL of potassium permanganate solution with a concentration of 0.30mol / L, heat and stir at 40°C to form a solution;

[0042] 2. Configure 150mL of manganese acetate solution with a concentration of 0.45mol / L, heat and stir at 40°C to form a solution;

[0043] 3. Slowly add the solution obtained in step 1 into a 1000mL three-necked flask, heat in an oil bath at 8...

Embodiment 3

[0052] An octahedral manganese oxide molecular sieve catalyst comprises the following components:

[0053] Pure cryptopotassium manganese dioxide is the active component, accounting for 95% of the total mass of the catalyst, and the doped transition metal Cu component accounts for 5% of the total mass of the catalyst, and the active component passes through Mn 7+ and Mn 2+ The reaction generates, and the molar ratio of the two is 0.72.

[0054] A method for preparing a metal oxide-loaded molecular sieve catalyst, which is prepared by a reflux method, specifically comprises the following steps:

[0055] 1. Prepare 300mL of potassium permanganate solution with a concentration of 0.40mol / L, heat and stir at 60°C to form a solution;

[0056] 2. Configure 300mL of manganese acetate solution with a concentration of 0.55mol / L, heat and stir at 60°C to form a solution;

[0057] 3. Slowly add the solution obtained in step 1 into a 1000mL three-necked flask, heat in an oil bath at 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com