Method for preparing two-phase catalytic micro-reactor

A microreactor, oil phase technology, applied in chemical instruments and methods, microsphere preparation, microcapsule preparations, etc., can solve problems such as application limitations, catalyst recycling difficulties, etc., to achieve simple operation, easy recovery and reuse, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

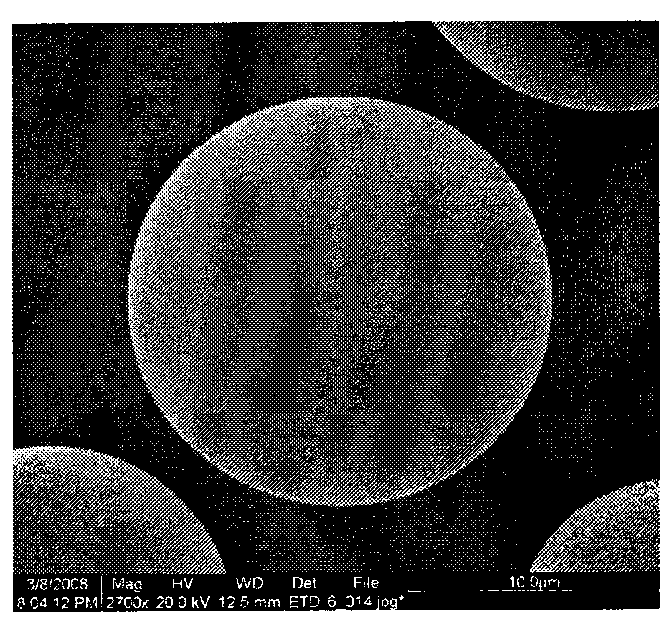

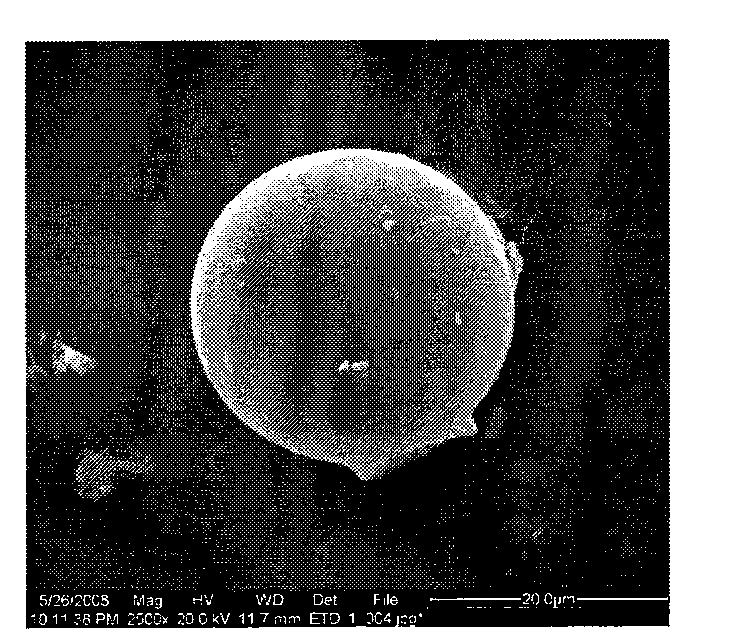

Image

Examples

Embodiment 1

[0036] (1) Preparation of synthetic template oil phase

[0037] Surfactant Span-80 was added into a beaker filled with cyclohexane, and the surfactant Span-80 and cyclohexane were mixed at a weight ratio of 1:90 to prepare an oil phase.

[0038] (2) Preparation of emulsion

[0039] Put the synthetic template oil phase prepared in step (1) into a three-necked flask, stir with a stirrer at a stirring speed of 800 rpm, and inject N at a flow rate of 2 to 3 mL / min. 2 , emulsified at 36°C for 40 minutes to make an emulsion;

[0040] (3) Preparation of water phase

[0041] Methacrylic acid MAA is a monomer, and the dosage is 22% of the weight of cyclohexane, neutralized with an aqueous solution of sodium hydroxide with a mass concentration of 30%, and the degree of neutralization is 60%, to make an aqueous solution A; agent, the dosage is 9.1% of the monomer weight; N, N'-methylenebisacrylamide is the crosslinking agent, the dosage is 13% of the monomer weight, and the ratio of a...

Embodiment 2

[0049] Same as the preparation method in Example 1, other conditions are as described in Example 1, in the preparation of synthetic template oil phase process step (1), surfactant Span-80 and cyclohexane are mixed with 1: 85 by weight Formulated as an oil phase. In the process step (2) of preparing the emulsion, under the condition of 20° C., the stirring speed is 400 rpm, and the emulsion is emulsified for 40 minutes to prepare the emulsion. In the preparation of the aqueous phase process step (3), the amount of N,N'-methylenebisacrylamide is 5% of the monomer weight. In the process step (4) of preparing the microgel, the stirring speed is 400 rpm. In the process step (5) of preparing PMAA / AEM composite microspheres, the microgel synthesized in step (4) is used as a template, and the microgel is mixed with 3v% AEM ethanol solution at a weight ratio of 1:3.0. In the process step (6) of preparing the PMAA / AEM / W2 microreactor, the PMAA / AEM composite microspheres were mixed wit...

Embodiment 3

[0051] The same as the preparation method in Example 1, other conditions are as described in Example 1, in the preparation of synthetic template oil phase process step (1), surfactant Span-80 and cyclohexane are mixed with 1:94 by weight Formulated as an oil phase. In the process step (2) of preparing the emulsion, under the condition of 40° C., the stirring speed is 1000 rpm, and the emulsification is carried out for 40 minutes to prepare the emulsion. In the preparation of the aqueous phase process step (3), the amount of N,N'-methylenebisacrylamide is 20% of the monomer weight. In the process step (4) of preparing the microgel, the stirring speed is 1000 rpm. In the process step (5) of preparing PMAA / AEM composite microspheres, the microgel synthesized in step (4) is used as a template, and the microgel is mixed with the ethanol solution of 3v% AEM in a weight ratio of 1: 3.4 . In the process step (6) of preparing the PMAA / AEM / W2 microreactor, the PMAA / AEM composite micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com