Method for preventing cavities from generating in deep groove insulation technology

A process and void technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as reducing insulation performance, and achieve the effect of ensuring insulation performance, eliminating sharp corners, and avoiding voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

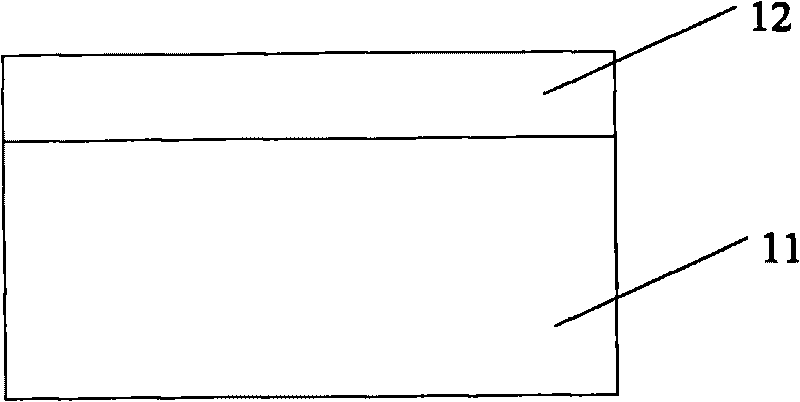

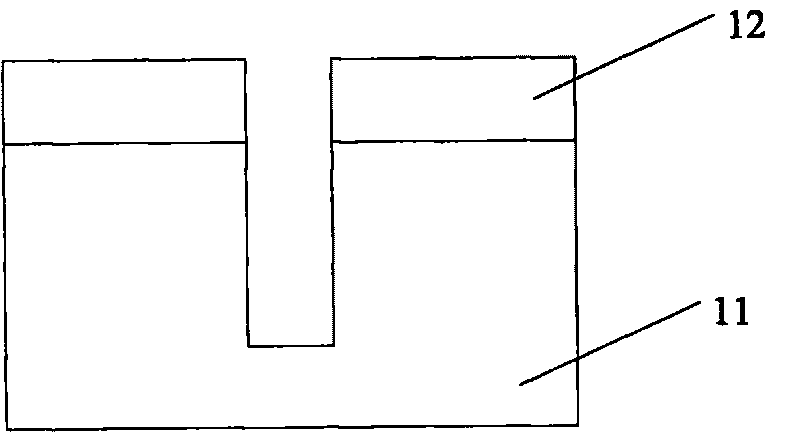

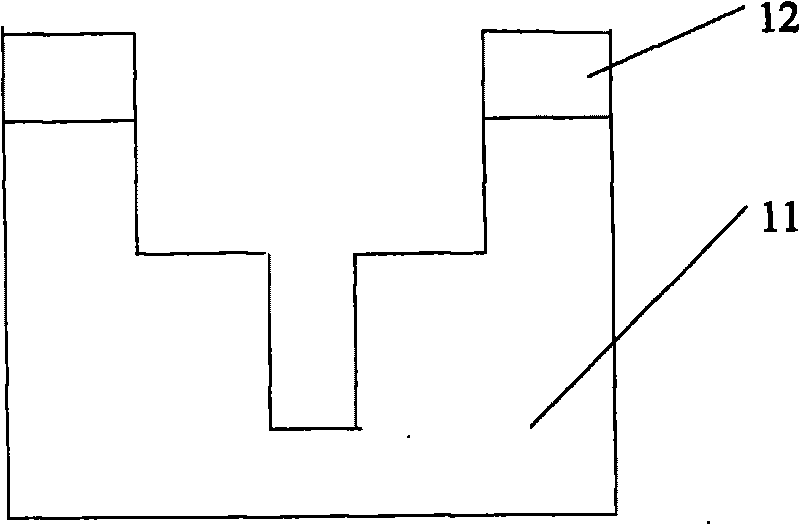

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] First, please refer to Figure 7 , Figure 7 It is a process flow diagram of a method for preventing voids in the deep trench insulation process of the present invention. As shown in the figure, the present invention includes the following steps:

[0017] Step 31: Form an active region protection layer on the semiconductor substrate. In actual operation, an oxide layer, such as a silicon oxide layer, is deposited on the substrate silicon first, and then a silicon nitride layer is deposited on the oxide layer. The substrate described in the invention is a substrate on which an oxide layer has been deposited on a silicon wafer;

[0018] Step 32: Etching the active region protection layer and the semiconductor substrate to form deep trenches, generally using silicon nitride as a hard mask, and defining steep grooves on the semiconduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com