Method for testing tensile mechanical performance of TiAl-base alloy

A test method and alloy-based technology, which is applied in the test field of tensile mechanical properties of TiAl-based alloys, can solve the problems of stress concentration and uneven force at the loading position of fixed samples, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The SEM in-situ tensile repeated loading and unloading test was performed on the TiAl-based alloy Ti-48Al-2Cr-2Nb with full-lamellar morphology after casting.

[0041] The first step: Ti-48Al-2Cr-2Nb alloy undergoes pretreatment, 175MPa, 1280℃, holding time of 4h hot isostatic pressing, and then annealing treatment at 800℃ for 12h.

[0042] Step 2: Design the sample size for processing and cutting.

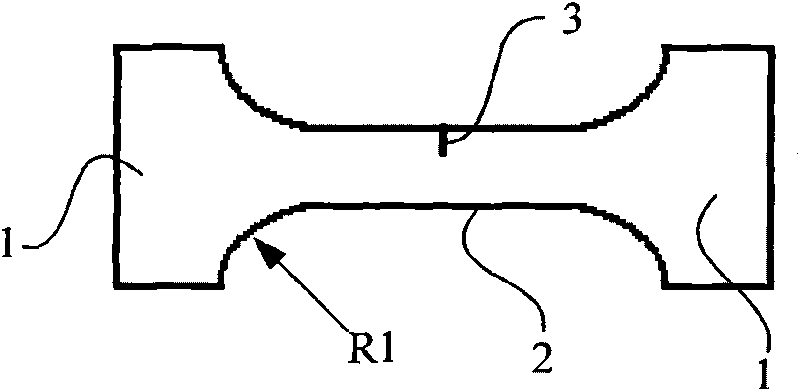

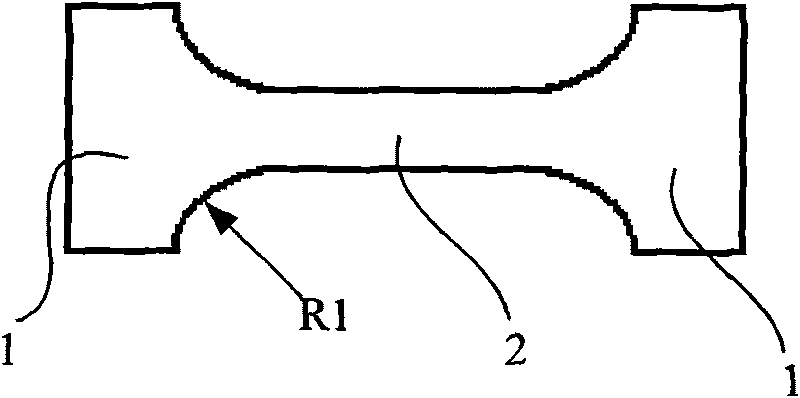

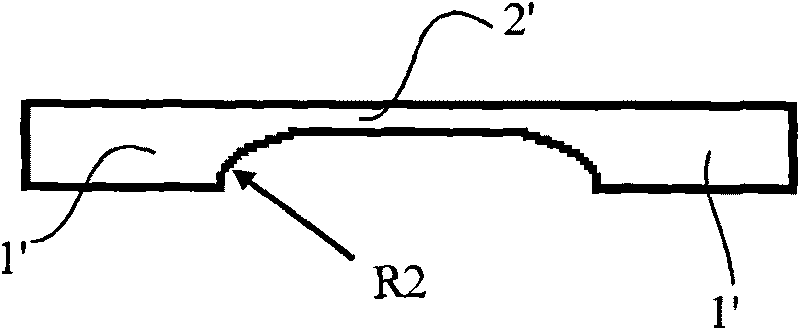

[0043] SEM of unnotched specimen Figure 1B As shown, the side thickness dimension Figure 1C Shown. The overall length of the sample is designed to be 35mm, the width of the clamping section 1 is 14mm, the length of the working section 2 is 17mm, and the width is 4mm. The fillet transition between the working section 2 and the clamping section 1 is 2mm at the R1 position. The thickness dimension is modified from the traditional in-situ tensile specimen dimension. One side of the 1'position of the clamping section at both ends is thickened, and the length of the clamping section ...

Embodiment 2

[0052] The Ti-47Al-2Cr-2Nb-1B alloy with full lamella structure was subjected to SEM in-situ tensile repeated loading and unloading tests.

[0053] The first step: First, the TiAl-based alloy ingot is pretreated. The pretreatment includes hot isostatic pressing and post-homogenization annealing. The hot isostatic pressing treatment temperature is 1280℃, the pressure is 175MPa, and the holding time is 4h. The annealing temperature is 800℃, and the holding time is 12h.

[0054] Step 2: Design the sample size for processing and cutting.

[0055] SEM of the notched specimen Figure 1B As shown, the side thickness dimension Figure 1C Shown. The overall length of the sample is designed to be 35mm, the width of the clamping section 1 is 14mm, the length of the working section 2 is 17mm, and the width is 4mm. The fillet transition between the working section 2 and the clamping section 1 is 2mm at the R1 position. The thickness dimension is modified from the traditional in-situ tensile spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com