Method for sensing automotive oil level and sensor

An oil level sensor and oil level sensing technology, which is applied in the field of sensing the oil level of automobile fuel tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The content of the present invention will be further described below in conjunction with the drawings:

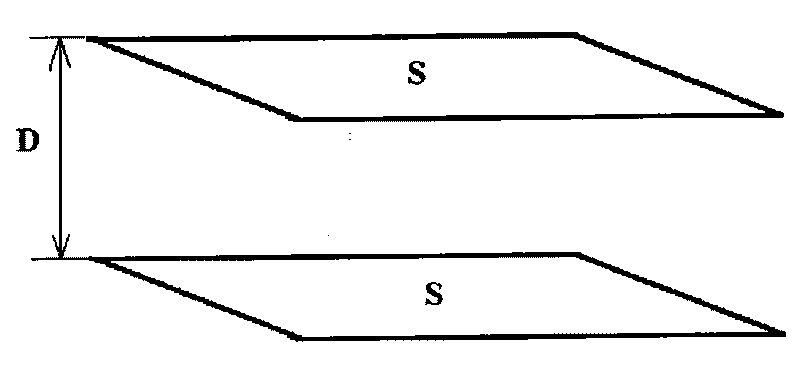

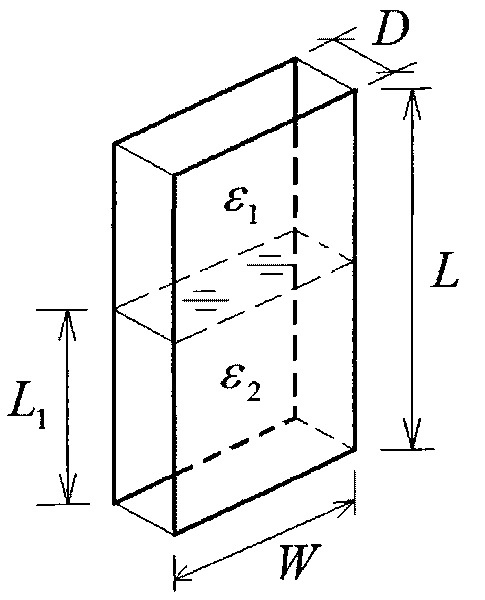

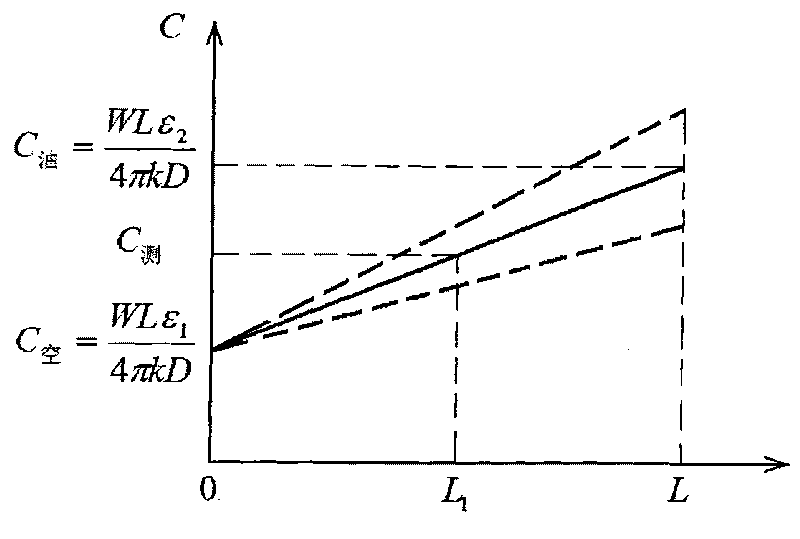

[0052] See Figure 4 , The automobile oil level sensor is composed of a measuring capacitor 1, a reference compensation capacitor 2, and a processing circuit. The measuring capacitor 1 is a parallel plate capacitor. The plates are not sealed and communicate with the oil space in the oil tank 3. Its length is close to or equal to the height of the oil tank 3. It is installed vertically on the inner side of the oil tank 3. The oil 4 Can enter between the two polar plates. The reference compensation capacitor 2 is a parallel plate capacitor whose capacitance value does not change during normal operation. Its capacitance value is equal to or proportional to the maximum capacitance value of the measurement capacitor 1. The reference compensation capacitor 2 and the measurement capacitor 1 are installed in the same fuel tank. In 3, the reference compensation capacitor 2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com