Method for improving properties of H13 die steel by adding nitrogen

A technology of mold steel and high performance, which is applied in the field of H13 mold steel, can solve problems such as not meeting the requirements of use, and achieve the effect of no reduction in toughness, high hardness, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

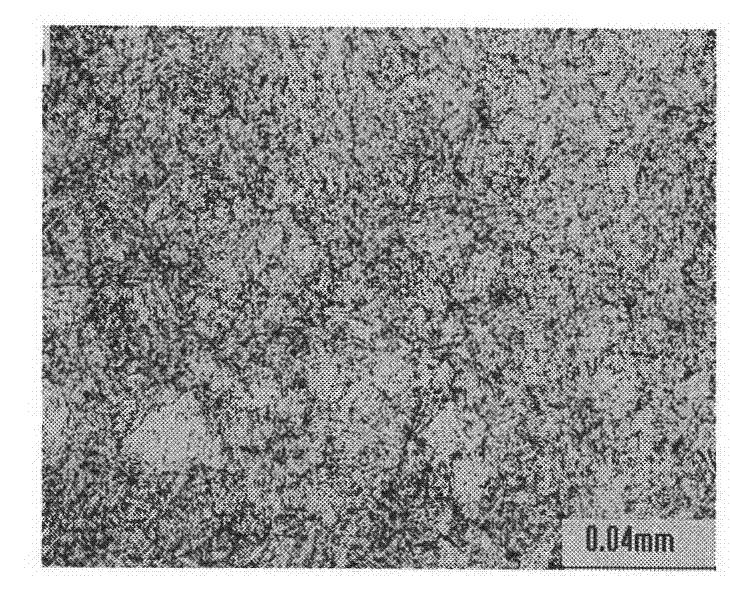

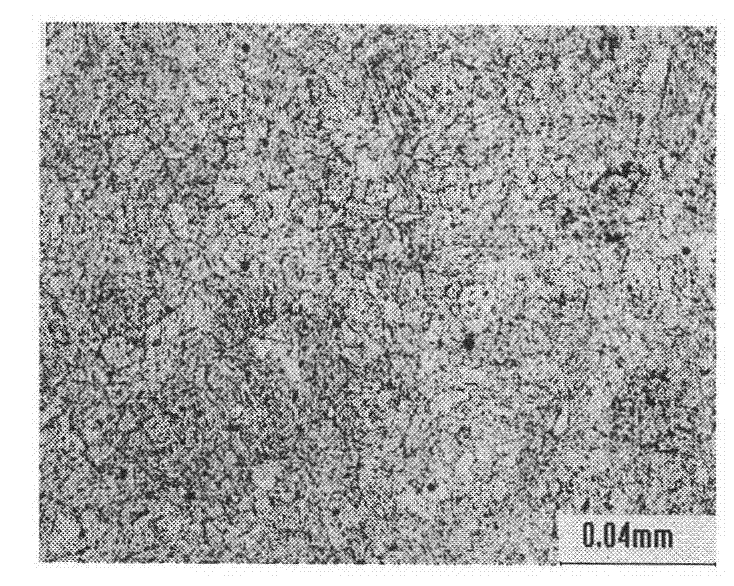

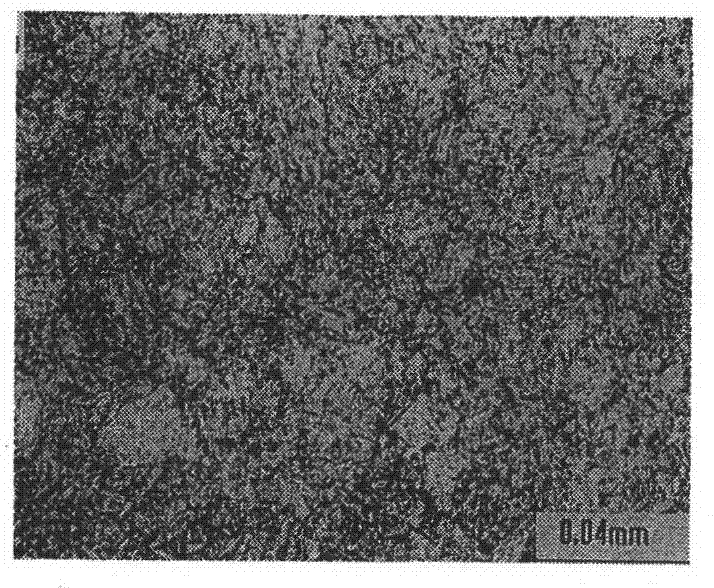

Image

Examples

Embodiment 1

[0019] Embodiment 1: Adopt the induction melting method described in the present invention, smelting the H13 die steel that adds nitrogen, chemical composition is as follows (%)

[0020] C

Embodiment 2

[0021] Embodiment 2: Adopt the induction melting method described in the present invention, smelting the H13 die steel that adds nitrogen, chemical composition is as follows (%)

[0022] C

Si

mn

Cr

Mo

V

P

S

N

0.29

0.96

0.30

5.03

1.27

0.92

0.0050

0.0049

0.021

[0023] Electroslag remelting, multi-directional forging and heat treatment were performed on the ingots in the above embodiments in the same process. When forging, the total forging ratio is ≥4, and the upsetting ratio of each process is ≥2. Immediately after forging, carry out isothermal spheroidizing annealing. The process is: (840-890°C) × (3h) + furnace cooling to (710-740°C) and holding for 3.5h, then furnace cooling to 500°C and air cooling. After annealing, the sample is preheated in stages at 680-720°C and 820-850°C, and finally heated to 1020°C and 1080°C respectively for 2 hours and then oil-que...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com