Anti-adhesive shoulder fixture for improving efficiency of endurance test

A long-lasting test and anti-adhesion technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of reduced strength of connecting threads and fixture buckles, low connection strength, and fixture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

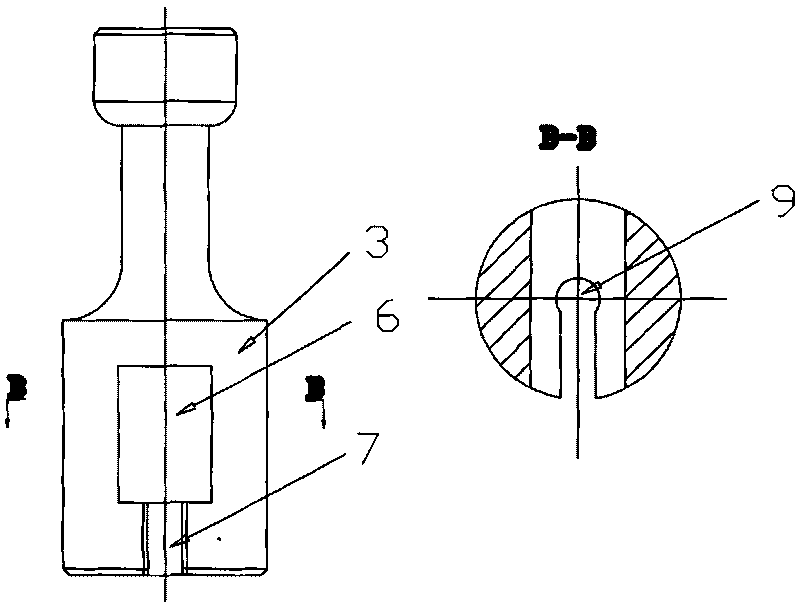

[0015] See attached Figure 1~5 As shown, this kind of anti-adhesion shoulder fixture that improves the efficiency of the durable test includes two large sliders 2 and two shoulder fixtures 3, wherein the external thread structure at one end of the large slider 2 is connected to the pull rod 1 of the testing machine, and its The other end is connected to the shoulder clamp 3, and the other end of the shoulder clamp 3 is connected to one end of the bar sample 5, the lower end of the large slider 2 and the shoulder clamp 3 is a cylindrical body, and it is characterized in that: 2 and the middle part of the lower end of the shoulder fixture 3 has a rectangular parallelepiped through hole 6 perpendicular to the axial direction, and a connecting bottom surface and rectangular parallelepiped through hole 6 is opened at the lower end of the large slider 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com