Laser welding clamp with double-sided inert gas protection

A laser welding fixture, inert gas technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problem of poor shielding gas protection, only contact with the back of the weld, and unable to achieve shielding gas protection, etc. Achieve the effect of improving the shielding effect of the shielding gas, realizing high-quality welding, and enhancing the protective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

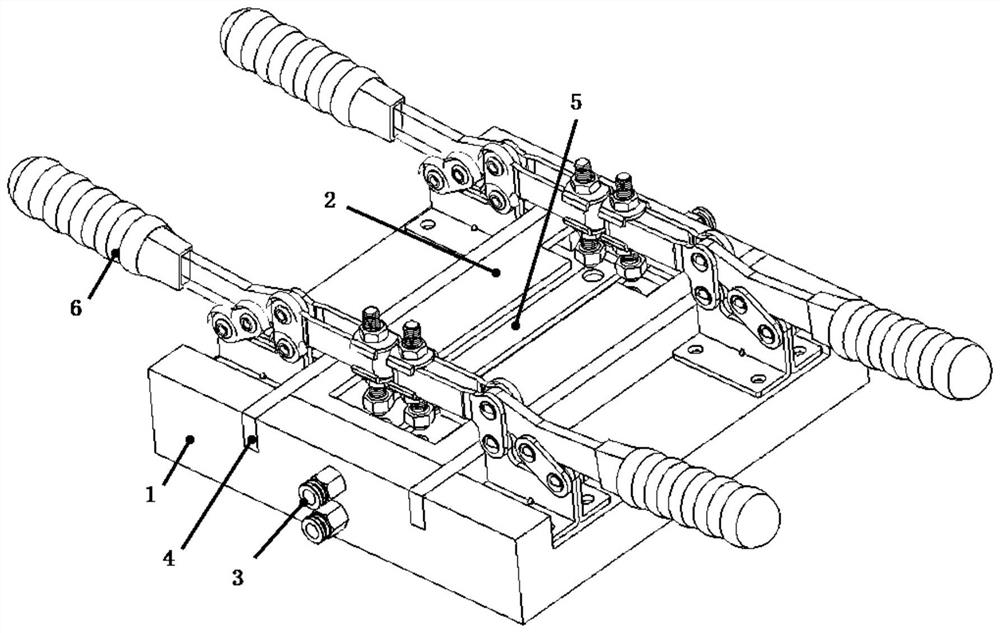

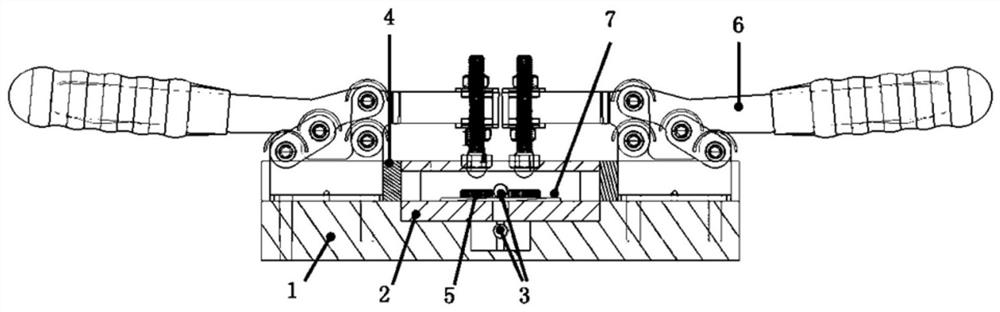

[0028] Such as Figure 1-2 As shown, a special fixture for laser welding with inert gas protection is provided with a ventilating base 1, a stage 2 arranged in the groove above the ventilating base 1, arranged on both sides of the stage 2 and passing through the ventilating base 1 The baffle plates 4 of the small grooves on both sides have a protective air groove at the center of the ventilation base 1, and two air holes are arranged in the protective air groove and above the protective air groove and are connected with the air nozzle 3. When in use, at first the quick clamp 6 is fixed on the ventilation base 1 by screws, the loading platform 2 is placed inside the ventilation base 1, the two pressing blocks 5 are placed in the loading platform 2, and the test plate 7 to be welded is butted on the The stage 2 is placed on the groove and pressed under the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com