Continuously variable transmission of snowmobile

A continuously variable transmission and snowmobile technology, applied in portable lifting devices, components with teeth, belts/chains/gears, etc., can solve the problem of small centrifugal force of driving wheel rollers, inability to effectively transmit torque, and small thrust of moving discs and other problems, to achieve the effect of large inclination angle, reliable and effective automatic adjustment, slow and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

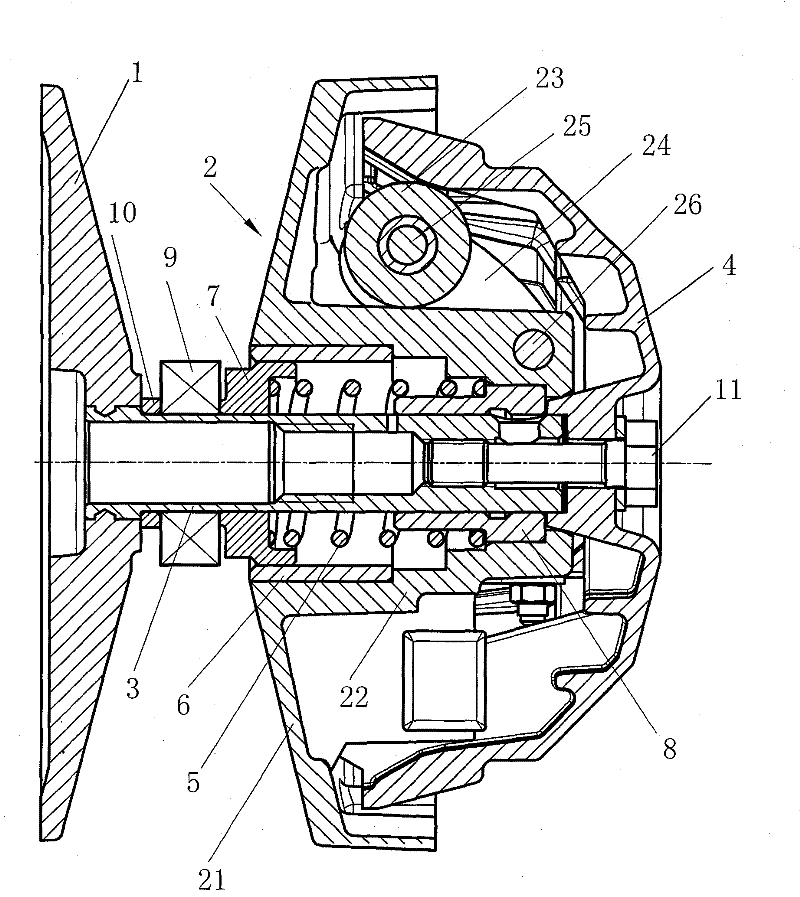

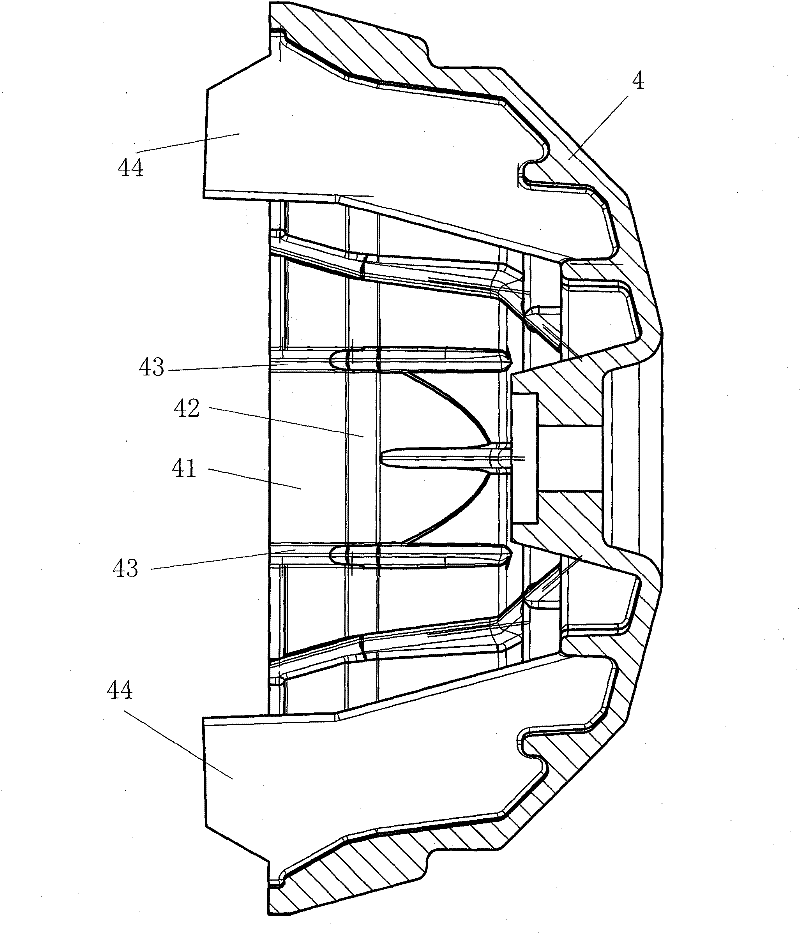

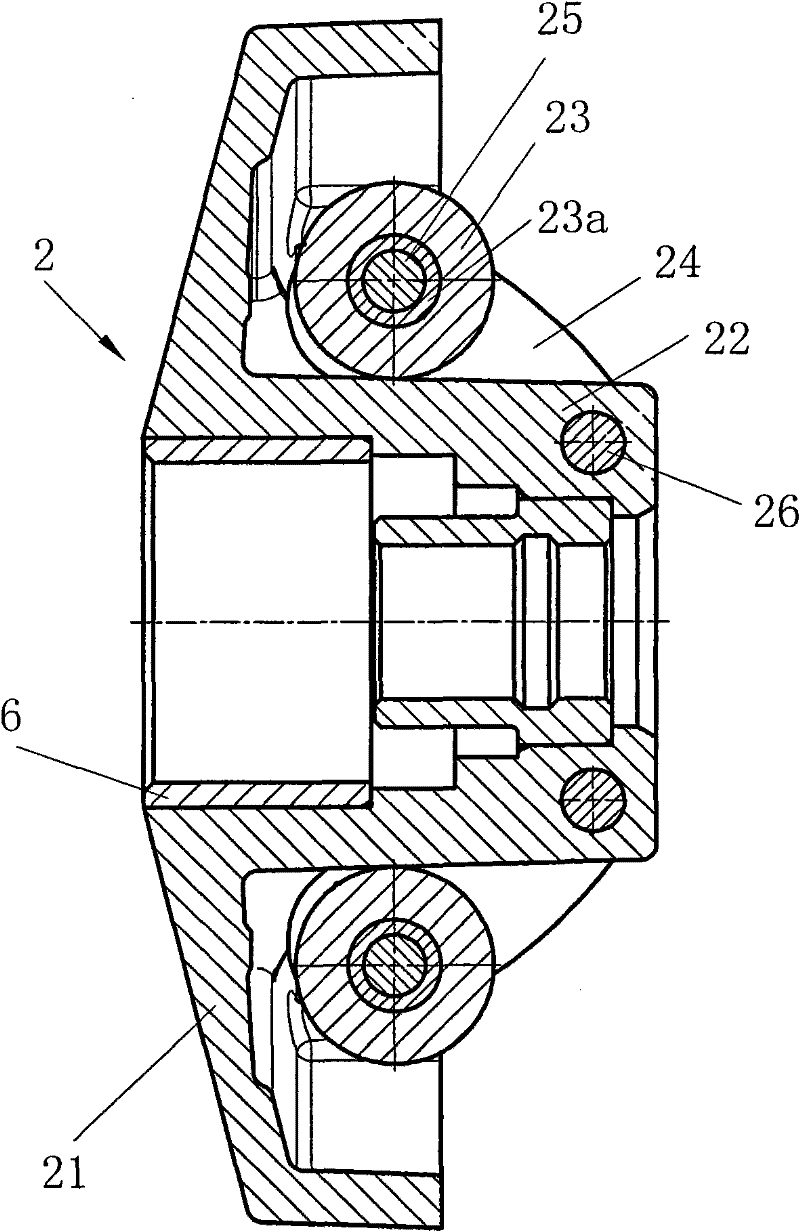

[0022] The present invention is a snowmobile continuously variable transmission, which comprises a driving wheel, a driven wheel and a transmission belt connecting the driving wheel and the driven wheel. The structure of the driven wheel is basically the same as that of the driven wheel of the motorcycle continuously variable transmission. It is a spring compression type. After the diameter of the wheel groove of the driving wheel becomes larger, the spring force of the driven wheel is overcome by the movement of the transmission belt to the outer circle of the driving wheel (because the length of the transmission belt remains unchanged), so that the driven plate of the driven wheel moves. Thereby, the diameter of the wheel groove of the driven wheel becomes smaller, and the speed change is realized. Such as figure 1 As shown, the driving wheel is mainly com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com