Water pump parallel machine set operation mechanism and control strategy simulation test device

A technology of simulation test and control strategy, applied in pump testing, machine/engine, mechanical equipment, etc., can solve the problem that the scheduling model, control model and energy saving strategy cannot be optimized to carry out experimental research, complex and continuous change laws cannot be simulated and cannot be simulated. Problems such as the operation status of the water pump or water pump unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

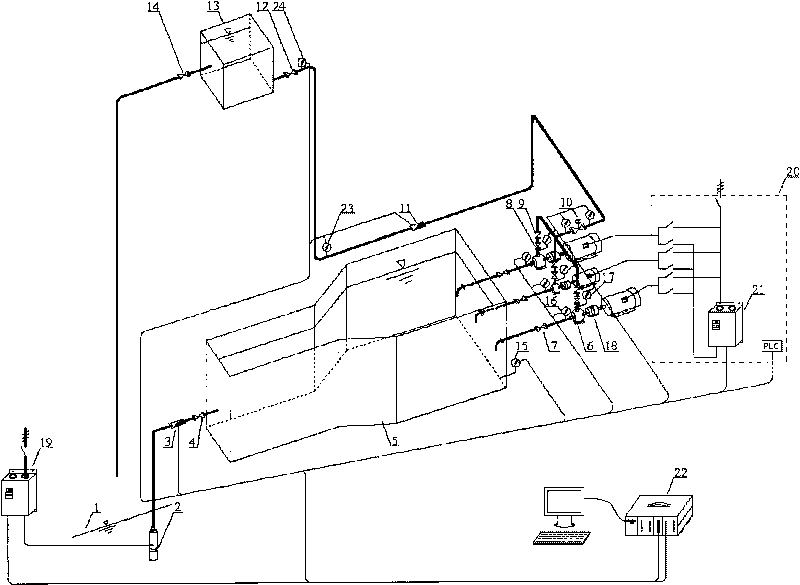

[0012] The submersible pump (2) is submerged in the pool (1), and the outlet of the submersible pump (2) is connected with the narrow end of the water inlet tank (5) through the pipeline, the water inlet flow meter (3) and the inlet valve (4) of the water inlet tank, Among the three parallel water pump units (6), two water pumps of the same size and one smaller water pump are used. The flow rate of the small pump is half of the flow rate of the large pump. Between the pumps, a butterfly valve (7) is installed between the inlet of each water pump and the wide side of the water inlet tank (5), and a butterfly valve (8) and a check valve (9) are installed at the outlet of each water pump, which are connected in parallel with the The automatic regulating valve (10) is connected, and then connected with the water outlet main pipeline, the outlet flowmeter (11) is installed in the middle of the main pipeline, and after the downstream vertically rises to a certain height, the valve (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com