Manufacturing method of base fabric of non-woven cleaning fabric

A wiping cloth and non-woven technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of different water absorption, wear resistance, difficulty in control, and product proportion reduction, and achieve wear resistance and dimensional stability Good, easy to operate and control, stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the non-woven wiping cloth base cloth of the present invention mainly comprises: (1) selection and mixing of raw materials; (2) carding into a web; (3) web laying; (4) acupuncture process; (5) heat setting process .

[0019] The preparation method of the present invention involves the raw material mixing and opening process, mainly to uniformly mix and fully open fiber raw materials of different specifications, and to avoid fiber damage during the specific implementation process, especially to select fibers of different fineness and length , it is necessary to configure reasonable process parameters. Mixing and opening good fiber raw materials is an important prerequisite for high-speed and high-quality production in the downstream.

[0020] The carding process is a key process in the production of non-woven materials. It mainly disperses the fibers into a single fiber state, which can further mix and improve the parallelism and straightness o...

Embodiment 1

[0035] (1) Use viscose / polyester mixture, the length is 38mm, the fineness is 2.2dtex, and the mixing ratio is 70 / 30. The raw materials are opened, mixed, combed into a web and laid into a multi-layer fiber web that meets certain specifications.

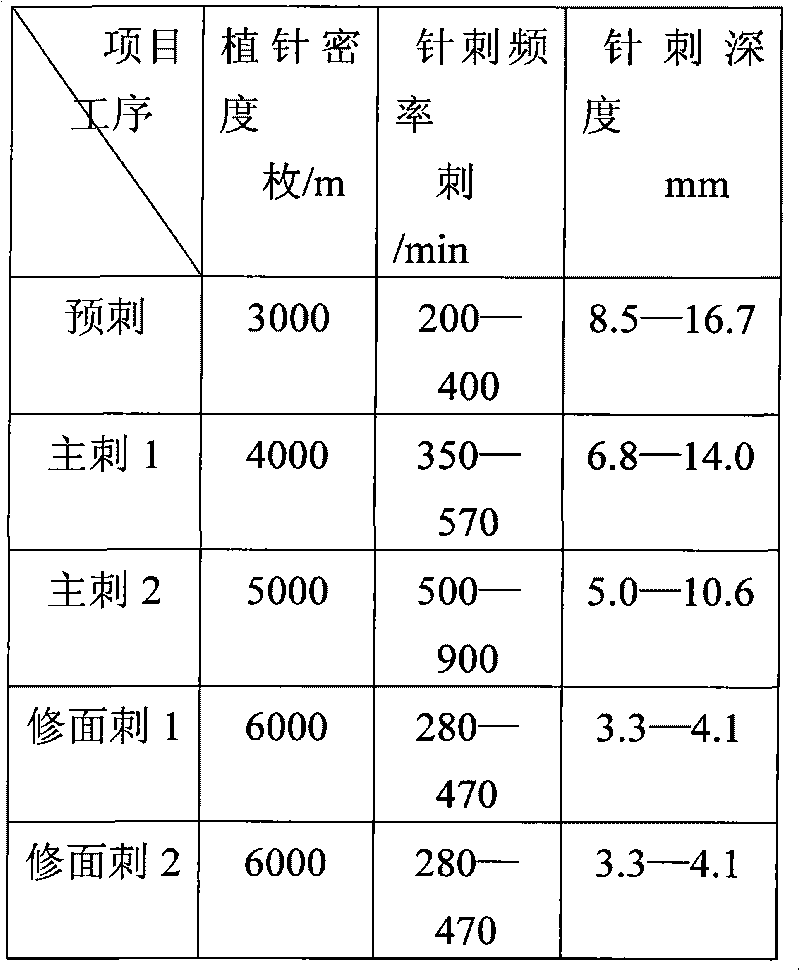

[0036] (2) The selection of acupuncture technology is shown in Table 3.

[0037] Table 3. Fabric acupuncture process parameters (1)

[0038]

[0039]

[0040] (3) The heat setting temperature is 170°C, and the setting time is 3.0min.

Embodiment 2

[0042] (1) Use viscose / polyester mixture with a mixing ratio of 50 / 50. Viscose length 38mm, fineness 4.0dtex; polyester length 72mm, fineness 2.2dtex. The raw materials are opened, mixed, combed into a web and laid into a multi-layer fiber web that meets certain specifications.

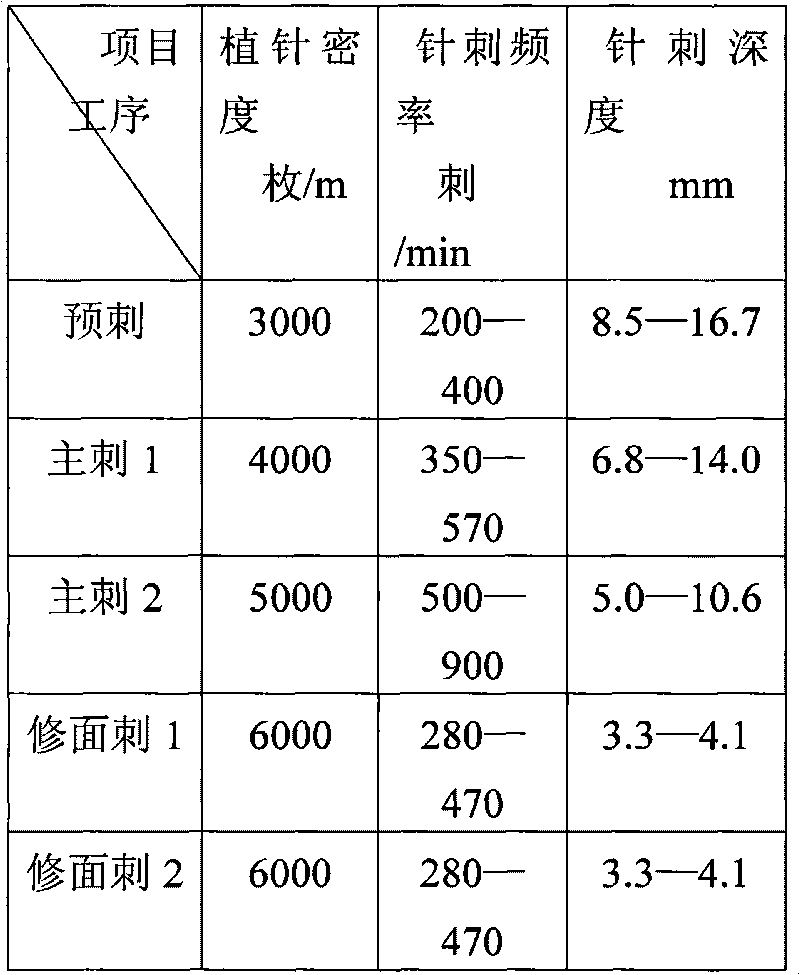

[0043] (2) The selection of acupuncture process is shown in Table 4.

[0044] Table 4. Fabric acupuncture process parameters (2)

[0045]

[0046] (3) The heat setting temperature is 185°C, and the setting time is 2.0min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com