Method for preparing Jiang-flavor liquor

A technology for Maotai-flavor liquor and fermented grains, which is applied in the field of winemaking, can solve the problems of large contact area and affect the yield of high-quality wine, and achieve the effect of improving the quality of wine and the yield of wine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the sauce-flavored liquor that the present embodiment enumerates may further comprise the steps:

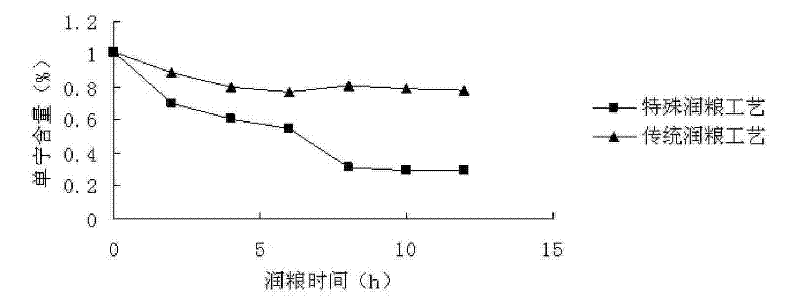

[0045] (1), under the sand:

[0046] Take 50% of the total grain sorghum and put it into a wooden barrel, add moistening water preheated to about 65°C to soak the grain for 8 hours, the water level of the added water is 10cm higher than the original grain, and the temperature in the wooden barrel is controlled during the soaking process. 40 ℃ ~ 60 ℃, change the water 3 times during soaking, moisten the grain until the water content in the raw material is 38% ~ 42%, let it dry and moisten the grain water;

[0047] Put the moistened raw grain on the retort and steam the grain for 2 hours, then take it out of the retort, let it cool to 28°C-32°C, add Daqu powder, the amount of koji added is 10% of the input amount, and the crushing specification of Daqu powder is that it does not pass through a 20-mesh sieve. 15% of the total Daqu powder, piled and ...

Embodiment 2

[0060] The preparation method of the sauce-flavored liquor that the present embodiment enumerates may further comprise the steps:

[0061] (1), under the sand:

[0062] Take 50% of the total grain sorghum and put it into a wooden barrel, add moistening water preheated to about 55°C to soak the grain for 12 hours, the water level of the added water is 30cm higher than the raw grain, and the temperature in the wooden barrel is controlled during the soaking process. 40 ℃ ~ 60 ℃, change the water once during soaking, moisten the grain until the water content in the raw material is 38% ~ 42%, let it dry and moisten the grain water;

[0063] Cook the moistened raw grain in a retort for 3 hours, take it out of the retort and let it cool to 28°C-32°C, add Daqu powder, the amount of added koji is 12% of the input amount, and the crushing specification of Daqu powder is that it does not pass the 20-mesh sieve to account for the total Daqu 20% of powder, stacked and fermented for 20 hou...

Embodiment 3

[0073] The preparation method of the sauce-flavored liquor that the present embodiment enumerates may further comprise the steps:

[0074] (1), under the sand:

[0075] Take 50% of the total grain sorghum and put it into a wooden barrel, add moistening water preheated to about 40°C to soak the grain for 12 hours, the water level of the added water is 15cm higher than the raw grain, and the temperature in the wooden barrel is controlled during the soaking process. 40 ℃ ~ 60 ℃, change the water 3 times during soaking, moisten the grain until the water content in the raw material is 38% ~ 42%, let it dry and moisten the grain water;

[0076] Steam the raw grain after moistening for 2 hours, take out the retort and let it cool to 28°C-32°C, add Daqu powder, the amount of added koji is 12% of the input amount, and the crushing specification of Daqu powder is that it does not pass the 20-mesh sieve to account for the total Daqu 15% of powder, stacked and fermented for 24 hours, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com