High oil-resistant rubber anti-corrosive lining and preparation method thereof

An oil-resistant rubber and anti-corrosion lining technology, applied in the field of chemical anti-corrosion material manufacturing, can solve the problems of poor acid resistance, poor alkali corrosion, shortened service life, and insufficient anti-corrosion safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

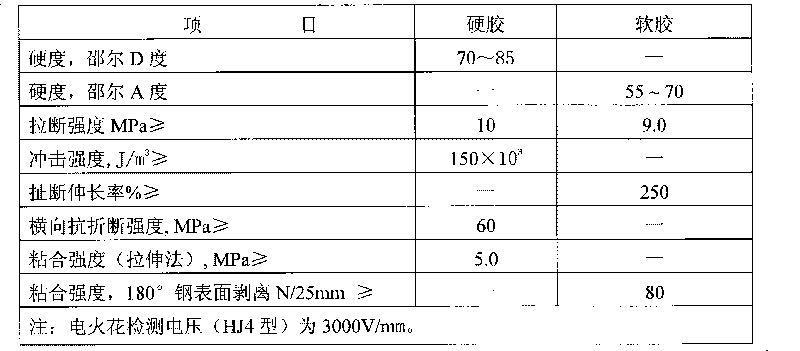

[0013] Embodiment 1: High oil-resistant rubber anti-corrosion lining, unit weight: 80-120 for high oil-resistant rubber, 8-12 for modified tackifier, 5-40 for vulcanizing agent, 40-60 for carbon black N550, and 40-60 for white Carbon black is 8-12, anti-aging agent 4020 is 1.5-2.5, anti-aging agent RD is 1-2, accelerator DM is 1-2. The tackifier refers to the condensation product of unsaturated alkylphenol and formaldehyde, such as phenolic resins. The vulcanizing agent refers to sulfur and sulfur-containing donor compounds.

Embodiment 2

[0014] Embodiment 2: On the basis of embodiment 1, the high oil-resistant rubber is 120, the modified tackifier is 12, the vulcanizing agent is 40, other materials are carbon black N550 is 60, white carbon black is 12, and the anti-aging agent 4020 is 2.5. The anti-aging agent RD is 2, and the accelerator DM is 2.

Embodiment 3

[0015] Embodiment 3: On the basis of embodiment 1, high oil-resistant rubber anticorrosion lining, high oil-resistant rubber is 80, modified tackifier is 8, vulcanizing agent is 5, other materials are carbon black N550 is 40, white carbon black is 8. The anti-aging agent 4020 is 1.5, the anti-aging agent RD is 1, and the accelerator DM is 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com