Method for separating metal or semiconductive carbon nanotubes

A technology of carbon nanotubes and separation methods, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] [Preparation of CNT dispersion]

[0076] Weigh 1.2 mg of HiPco-CNT (Lot number P0276, Carbon Nanotechnologies. Inc. TX, diameter 1.0±0.3 nm) sample, and add 3.2 ml of 1.2% SDS-0.8% SC mixed aqueous solution. Place the above solution in a circulating tap water bath, use a drill-type ultrasonic breaker (Misonix XL2000) to sonicate continuously for 2 hours (level 6), centrifuge for 4 hours, and take the supernatant. This solution contains many isolated and monodisperse CNTs. Sucrose (50% aqueous solution) with a final concentration of 10% was added to the supernatant to prepare a sample for electrophoresis.

[0077] [Gel electrophoresis]

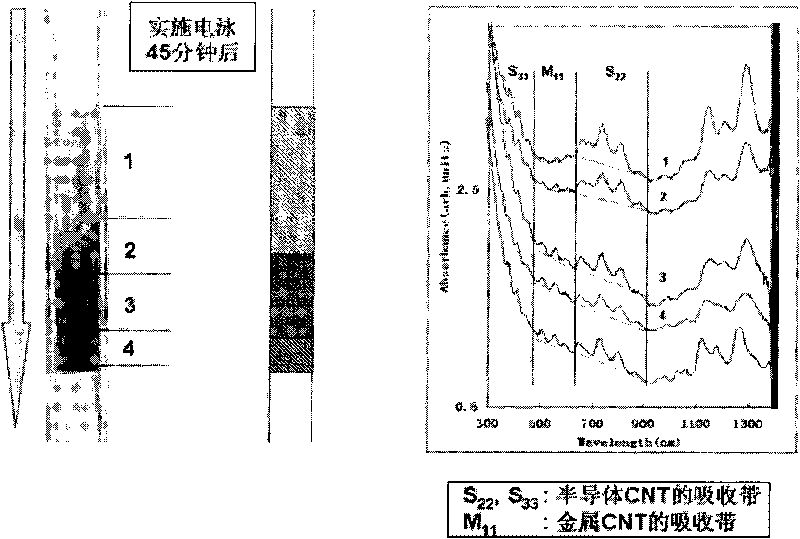

[0078] The gel for electrophoresis (0.4% low melting point agarose added with 1 / 10 of the amount of surfactant when ultrasonic dispersion is added, in this case 0.12% SDS and 0.08% SC; and TB buffer) are prepared in In a quartz tube with a length of 10 cm, an outer diameter of 7 cm, and an inner diameter of 6 cm. The TB buffer containing 1 / 1...

Embodiment 2

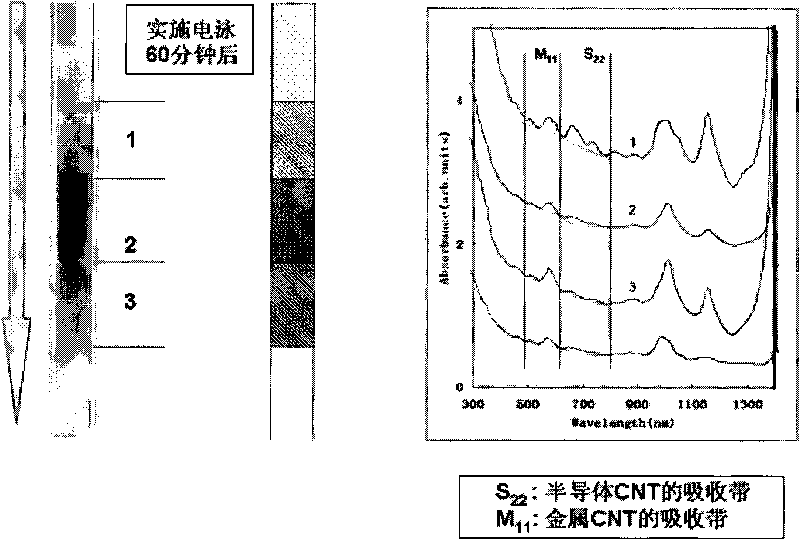

[0084] The difference from Example 1 is:

[0085] For carbon nanotubes, CoMoCAT-CNT (SouthWest NanoTechnologies Inc) is used instead of HiPco-CNT, and the surfactant is a mixture of 2% SDS instead of 1.2% SDS-0.8% SC. The running buffer uses TAE instead of TB, and no surfactant is added. figure 2 Shows the gel condition photos, pattern diagrams, and absorption spectrum test results after 60 minutes of electrophoresis. Compared with the absorption spectrum of the CNT dispersion before electrophoretic separation, it is visually confirmed that the light green part (1) has an increase in the proportion of semiconducting CNTs, while the light gray pre-electrophoresis part (4) An increase in the ratio of metallic CNTs occurred. The ratio of the semiconducting and metallic CNTs in the middle part is almost unchanged from the sample before separation. This result shows that, like HiPco-CNT, metallic and semiconducting CNTs can also be separated when using CoMoCAT-CNT.

[0086] In addit...

Embodiment 3

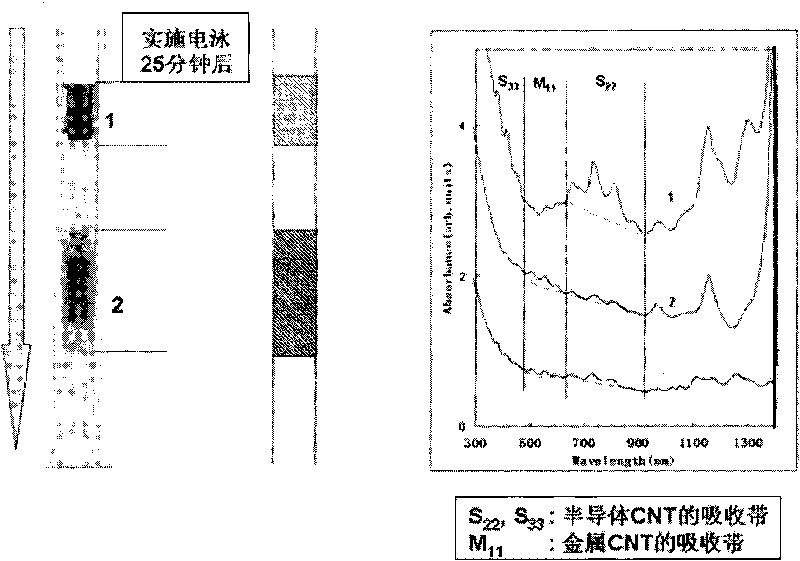

[0088] The difference from Example 1 is:

[0089] After heating and dissolving the 0.8% agarose gel added with × 2TB buffer, it is mixed with 1:1 equal volume of HiPco-CNT dispersion in a molten state and cooled at room temperature to form a carbon nanotube package. As a sample for electrophoresis. The surfactant uses 2% SDS instead of 1.2% SDS-0.8% SC mixture, and the electrophoresis time is 25 minutes. image 3 Shows the photo of the gel condition at the end of the electrophoresis, its pattern diagram and the results of the absorption spectrum test. The difference from the result of Example 1 is that green (1) semiconducting CNTs that are located in the carbon nanotube package and do not move with the electrophoresis and are stationary are separated and swim out of the carbon nanotube package. , The metallic CNT in light brown red (2) at the front of electrophoresis. There are almost no carbon nanotubes in the middle part. The results show that this method overcomes the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com