Molding roller of thin-wall titanium welding pipe

A technology of titanium welded pipes and rollers, which is applied in the production field of thin-walled titanium welded pipes, can solve the problems of scratching thin-walled titanium welded pipes, build-up, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

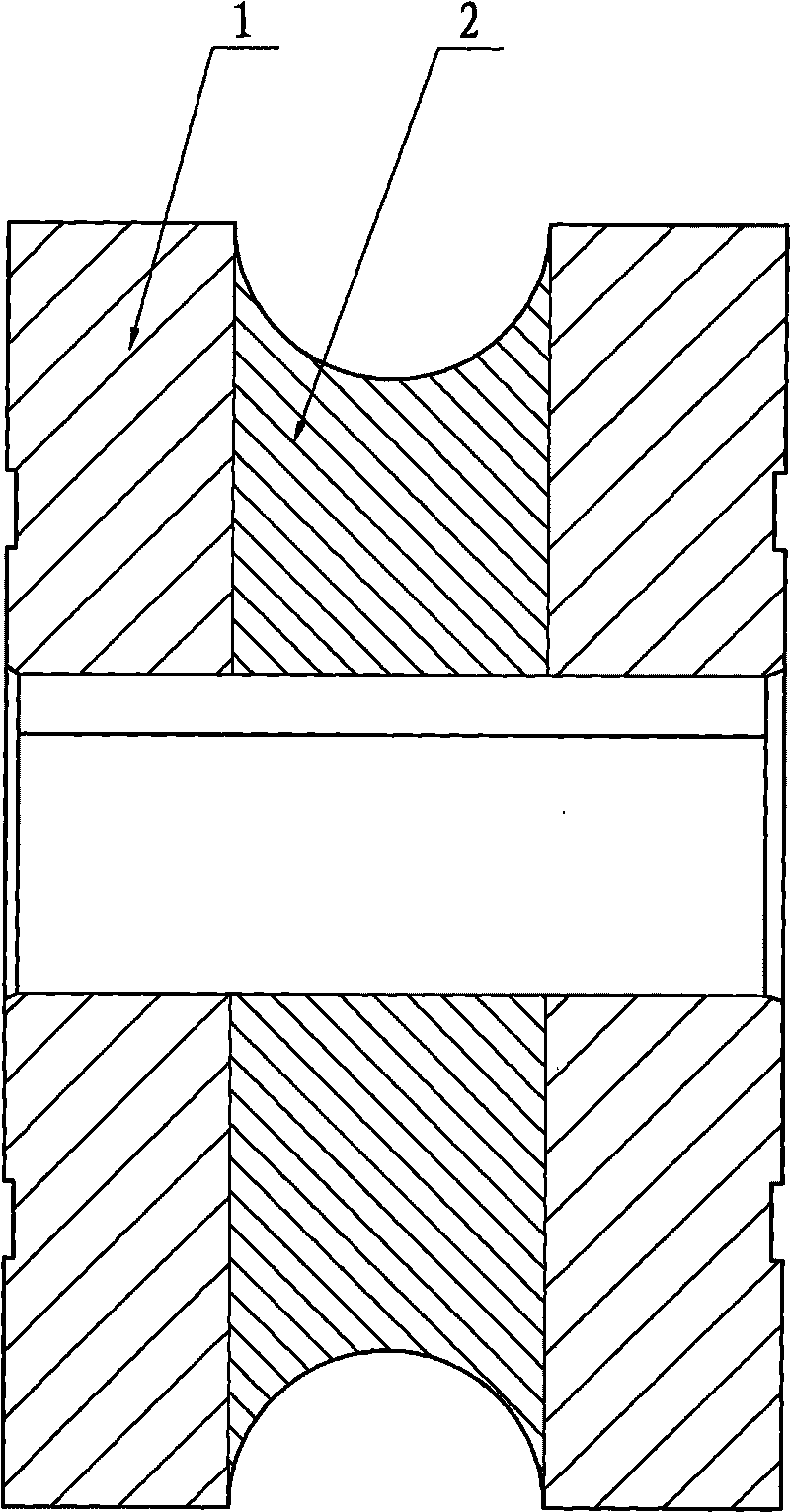

[0012] Depend on figure 1 It can be seen that a thin-walled titanium welded pipe forming roll includes a fine forming roll pair and a sizing roll pair made of a copper alloy material, and a forming roll 1 corresponding to the weld seam in the fine forming roll pair and the sizing roll pair. Part 2 is a wear-resistant material that is incompatible with titanium.

[0013] Both ends of the forming roll 1 of the present invention are made of copper alloy material, and the forming part 2 is made of a wear-resistant material incompatible with titanium (the alloy tool steel Cr12Mov alloy material in this embodiment). The Cr12Mov material is quenched, and the hardness is HRC60. After the two grinding surfaces are finely ground, they are clamped with copper alloy materials on both sides and processed as a whole to form the forming roll 1 . Since the hardness and rigidity of Cr12Mov alloy material is better than that of copper alloy material, the service life of forming roll 1 is impro...

Embodiment 2

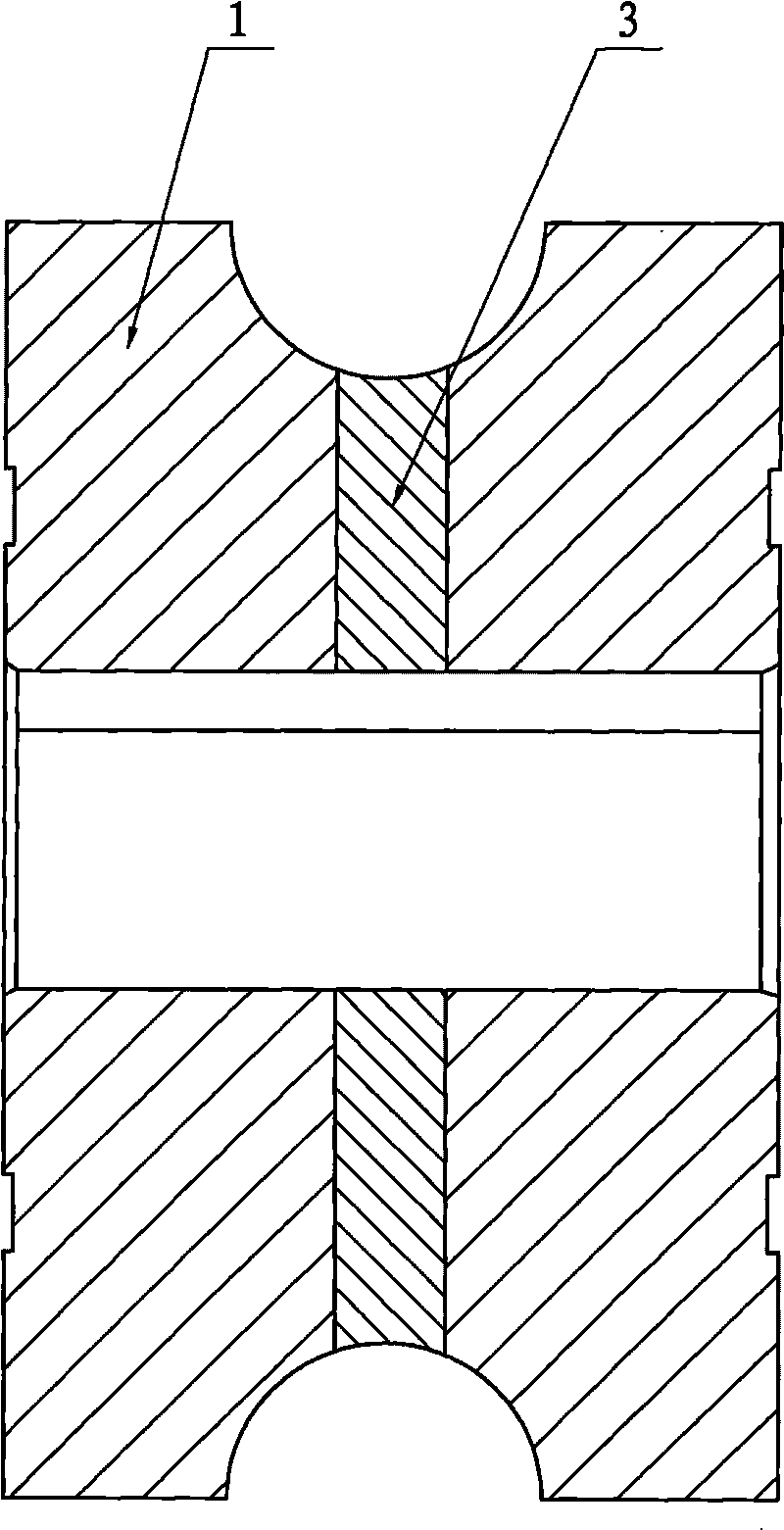

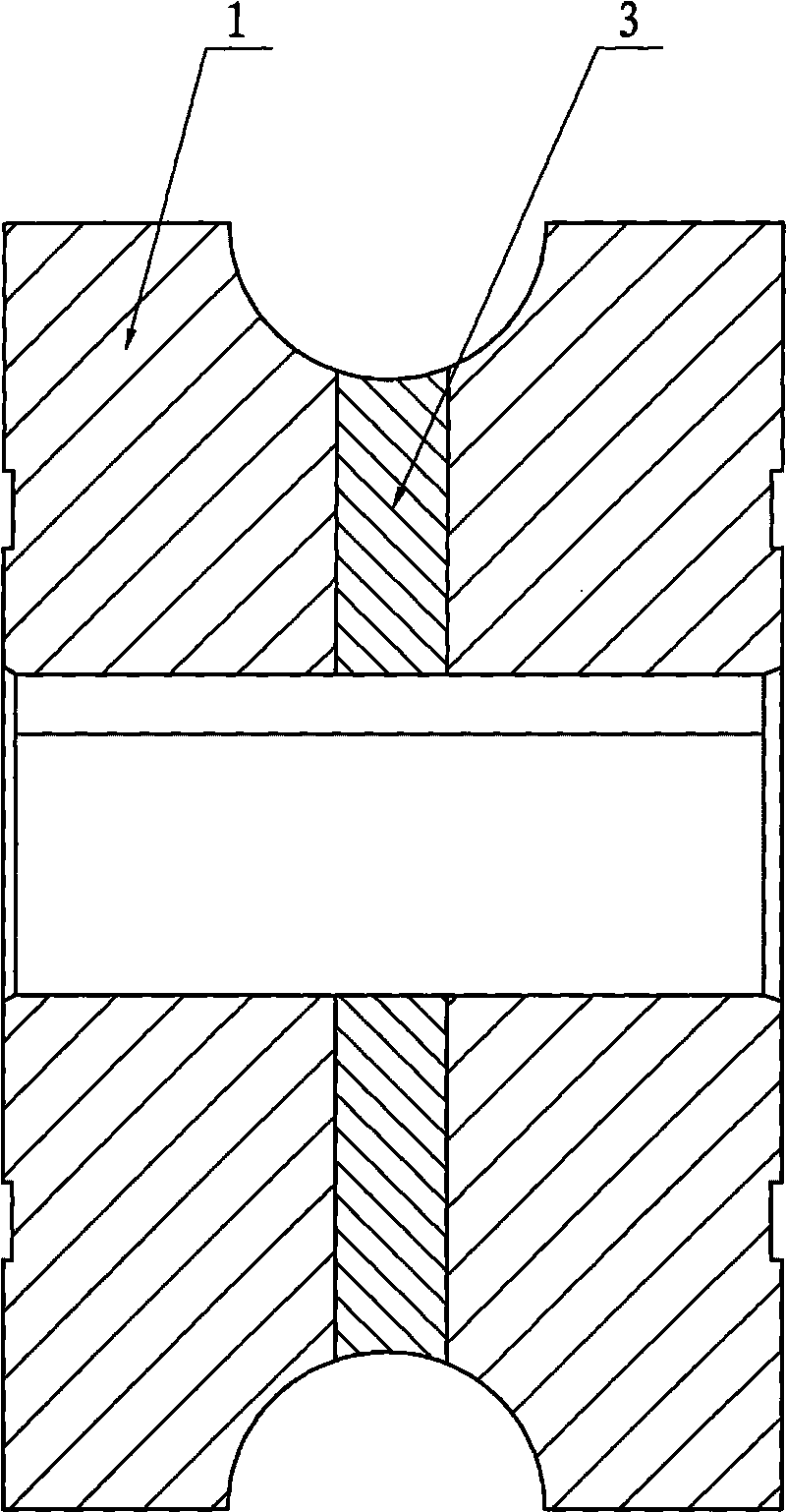

[0015] Because buildup generally occurs in the area corresponding to the weld seam of the titanium welded pipe in the forming part 2, that is, the buildup part 3, therefore, the buildup part 3 in the forming part 2 of the present invention is a wear-resistant material that is incompatible with titanium ( This embodiment is chrome-nickel steel material). The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com