Gas-sensitive transducer with nano wall structure and preparation method thereof

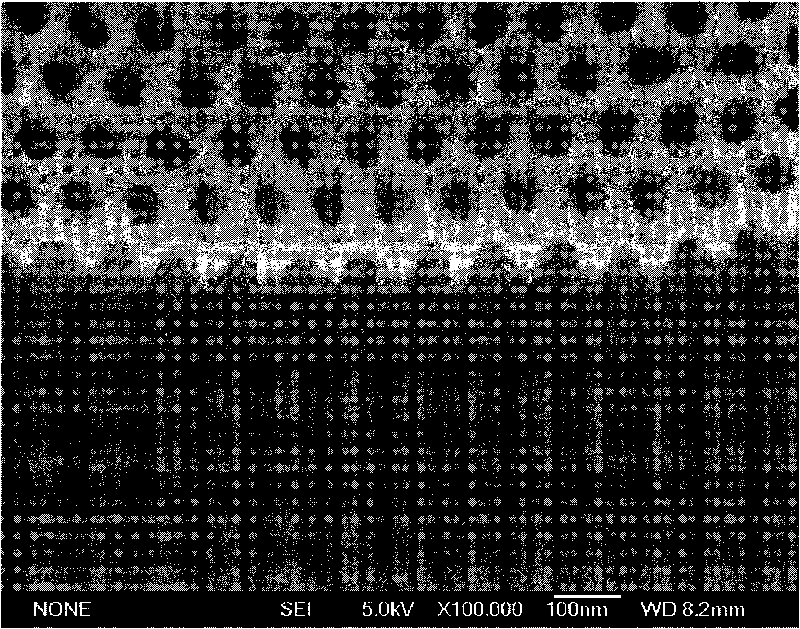

A gas-sensing sensor and nano-wall technology, applied in the field of gas-sensing sensors, can solve problems such as poor selectivity and stability, and achieve the effects of controllable structure, improved sensitivity and performance optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

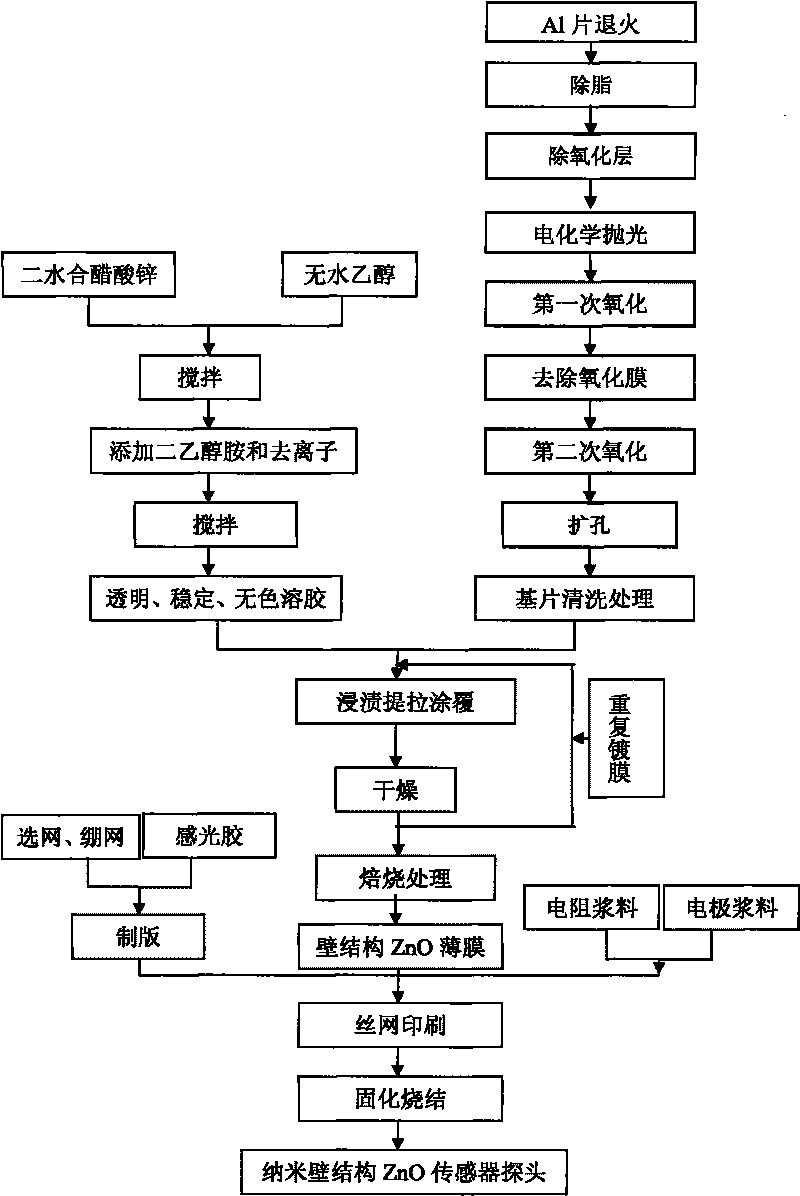

[0018] The preparation method specifically comprises the following steps:

[0019] 1) Pretreatment of the substrate made of pure aluminum:

[0020] High-temperature annealing is used to eliminate the residual stress of the aluminum sheet, and electrochemical polishing is used to eliminate scratches on the surface of the aluminum sheet, in order to avoid scratches from destroying the regularity of the oxidation growth of the aluminum sheet;

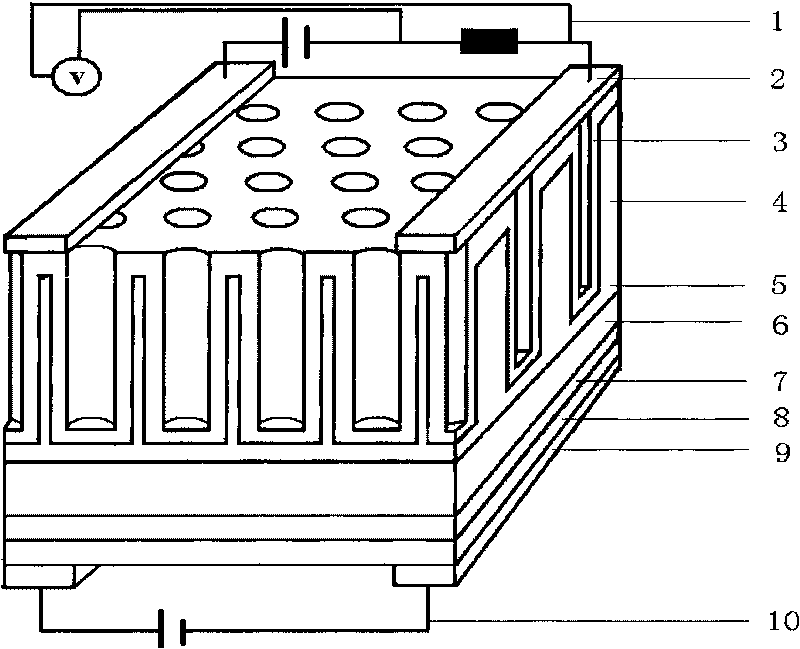

[0021] 2) Carry out anodic oxidation to step 1) gained pure aluminum substrate 6:

[0022] It is divided into three steps, that is, primary anodic oxidation, removal of the oxide film of primary oxidation and secondary anodic oxidation; finally, a porous anodic oxidation template with porous alumina 4 on the surface and dense alumina 5 on the bottom layer is formed;

[0023] 3) Reaming the porous anodized template obtained in step 2):

[0024] Etching the formed pores to increase their diameter;

[0025] 4) Sensitive material deposition...

Embodiment 1

[0062] Embodiment 1: technical solution

[0063] Aluminum base pretreatment

reason

Anodic oxidation of pure aluminum substrates

change

Plating of sensitive materials

Printed electrodes and circuits

Fire: 480°C

keep warm for 1 hour

annealing. surface

0.2mol / l

NaOH solution

Soak 2

minutes, then

at 1:4

perchloric acid and

Absolute ethanol

hybrid electric

20V in solution

Electrolytic throwing

Light for 2 minutes.

One-time anodizing: with

made of 0.5mol / l

Oxalic acid solution, at 30V,

Oxidation 4 at 10°C

Hour. remove primary oxygen

Chemical film: 6wt% phosphoric acid

solution and 1.8wt% of

chromic acid solution

Soak in mixed solution at 60°C

3 hours for oxidation

membrane. Secondary anodizing:

Secondary oxidation time 5 hours

, the parameters are the same...

Embodiment 2

[0066] Embodiment 2: technical solution

[0067] Aluminum base pretreatment

Anodic Oxidation of Pure Aluminum Substrate

Plating of sensitive materials

Printed electrodes and circuits

Same as Example 1

1.5mol / l in primary anodic oxidation

of sulfuric acid solution at 30V at 10°C

The next oxidation is 3 hours. The rest are the same

Example 1

Same as Example 1

When configuring the resistance slurry, the last stirring

Organic vehicle is 70%. Electrode paste with

Set time, final ultrasonic pulverization time 2

Hour. All the other are the same as embodiment 1

[0068] The performance of the sensor prepared by embodiment 2:

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com