Processing method of asparagus and peach wine

A processing method and technology of asparagus, applied in the processing field of asparagus peach wine, can solve the problems of easy softening and rot, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Embodiment 1, a kind of processing method of asparagus peach wine comprises the following steps:

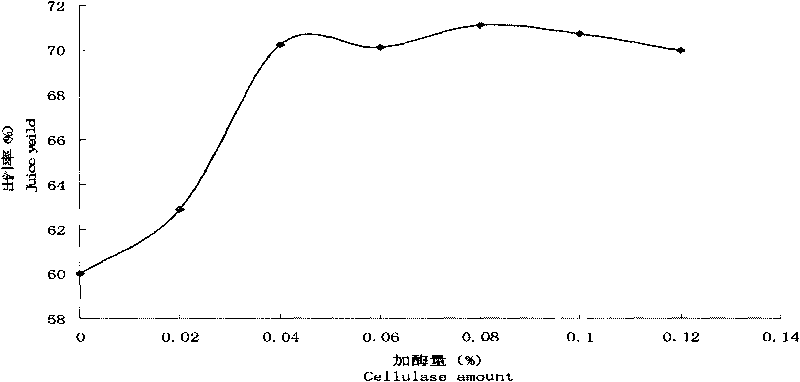

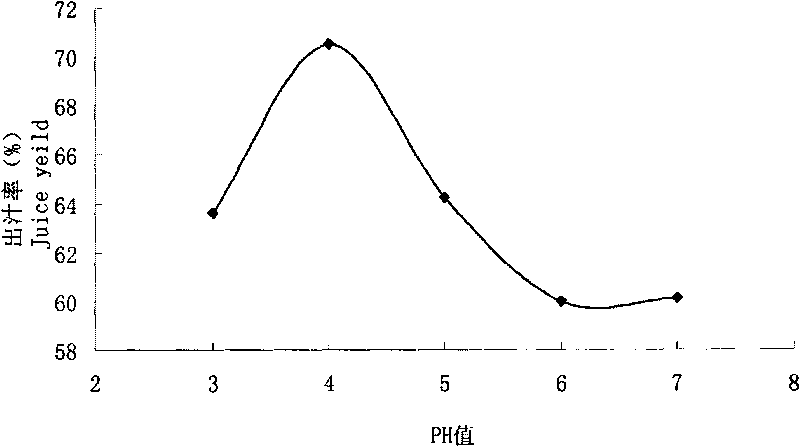

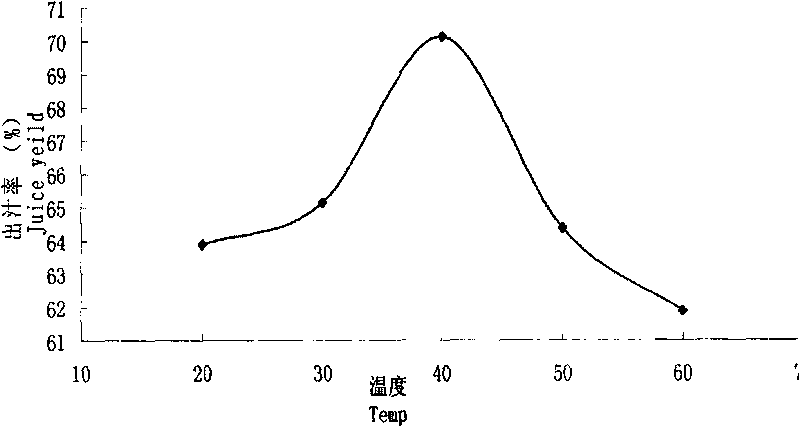

[0124] (1) Preparation of asparagus juice: Weigh a certain amount of asparagus leftovers, put them into a high-speed tissue masher at a material-to-water ratio of 1:1, beat for 3 minutes, add cellulose enzyme liquid with a mass fraction of 0.08% to the asparagus and evenly slurry, the enzymolysis time is 40min under the conditions of pH value 3 and temperature 45°C in a water bath, and finally the enzymolysis asparagus slurry is filtered with a 200-mesh filter cloth to obtain asparagus juice.

[0125] (2) Preparation of peach juice: Weigh a certain amount of peaches, put them into a high-speed tissue masher at a material-to-water ratio of 1:1, beat for 2 minutes, and add pectin enzyme solution to the peaches at a mass fraction of 0.5%. In the slurry, under the conditions of pH value 4 and temperature 50°C, keep it in a constant temperature water bath for 35 minutes, and fi...

Embodiment 2

[0133] Embodiment 2, a kind of processing method of asparagus peach wine, comprises the following steps:

[0134] (1) Preparation of asparagus juice: Weigh a certain amount of asparagus leftovers, put them into a high-speed tissue masher at a material-to-water ratio of 1:1, beat for 3 minutes, add cellulose enzyme liquid with a mass fraction of 0.04% to the asparagus and evenly In the slurry, the enzymolysis time is 50min under the conditions of pH value 5 and temperature 35°C in a water bath, and finally the enzymolysis asparagus slurry is filtered with a 200-mesh filter cloth to obtain asparagus juice.

[0135] (2) Preparation of peach juice: Weigh a certain amount of peaches, put them into a high-speed tissue masher at a material-to-water ratio of 1:1, beat for 2 minutes, and add pectin enzyme solution to the peaches at a mass fraction of 0.2%. In the slurry, under the conditions of pH value 6 and temperature 35°C, keep it in a constant temperature water bath for 50 minutes...

Embodiment 3

[0143] A kind of processing method of embodiment 3 asparagus peach wine, comprises the following steps:

[0144] (1) Preparation of asparagus juice: Weigh a certain amount of asparagus leftovers, put them into a high-speed tissue masher at a material-to-water ratio of 1:1, beat for 3 minutes, add cellulose enzyme liquid with a mass fraction of 0.06% to asparagus and evenly slurry, under the condition of pH value 4.5, temperature 40 ℃ water bath condition, enzymolysis time 45min, finally filter the asparagus slurry after enzymolysis with 200 mesh filter cloth to obtain asparagus juice.

[0145] (2) Preparation of peach juice: Weigh a certain amount of peaches, put them into a high-speed tissue masher at a material-to-water ratio of 1:1, beat for 2 minutes, and add pectin enzyme solution to the peaches in a ratio of 0.45% by mass fraction. In the slurry, under the conditions of pH value 5.5 and temperature 45°C, keep it in a constant temperature water bath for 40 minutes, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com