Special stainless steel electrode for deep refrigerating project

A stainless steel and engineering technology, applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of poor welding processability, reducing the ferrite content of the weld, affecting the thermal cracking resistance of the weld, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

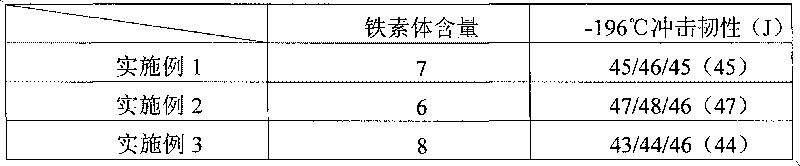

[0022] Embodiment 1, get rutile 38kg; Marble 13kg; Titanium dioxide 3kg; Quartz 1kg; Mica 5kg; Ferrosilicon 6kg; and calcium oxide, the remaining ingredients are a small amount of other oxides, used to improve the pressure coating of the electrode) 1kg; sodium carbonate 3kg; cryolite 5kg; Mix evenly in the medium, press-coat it on the H00Cr21Ni10 stainless steel welding core with a hydraulic machine, let the electrode dry naturally for 24 hours, and then dry it. The ferrite content and impact toughness test values of the deposited metal are shown in Table 2.

Embodiment 2

[0023] Embodiment 2, get rutile 46kg; Marble 14kg; Titanium dioxide 2kg; Quartz 3kg; Mica 4kg; Ferrosilicon 5kg; and calcium oxide, the rest of the ingredients are a small amount of other oxides, used to improve the pressure coating of the electrode) 2kg; sodium carbonate 1kg; cryolite 7kg; Mix evenly in the medium, press-coat it on the H00Cr21Ni10 stainless steel welding core with a hydraulic machine, let the electrode dry naturally for 24 hours, and then dry it. The ferrite content and impact toughness test values of the deposited metal are shown in Table 2.

Embodiment 3

[0024] Embodiment 3, get rutile 43kg; Marble 15kg; Titanium dioxide 1kg; Quartz 2kg; Mica 6kg; Ferrosilicon 4kg; and calcium oxide, the rest of the ingredients are a small amount of other oxides, used to improve the pressure coating of the electrode) 3kg; sodium carbonate 2kg; cryolite 4kg; Mix evenly in the medium, press-coat it on the H00Cr21Ni10 stainless steel welding core with a hydraulic machine, let the electrode dry naturally for 24 hours, and then dry it. The ferrite content and impact toughness test values of the deposited metal are shown in Table 2.

[0025] Table 2 The ferrite content and impact toughness of the deposited metal in the embodiment

[0026]

[0027] Note: In the impact toughness, the average value of the three values is in the brackets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com