Method for stockpiling tailings from beneficiated bauxite

A bauxite and tailings technology, applied in bauxite washing, metal beneficiation tailings or non-metal beneficiation tailings storage, beneficiation tailings storage field, can only reach 25%- 30%, high operating cost, high paste concentration, to achieve the effect of easy implementation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

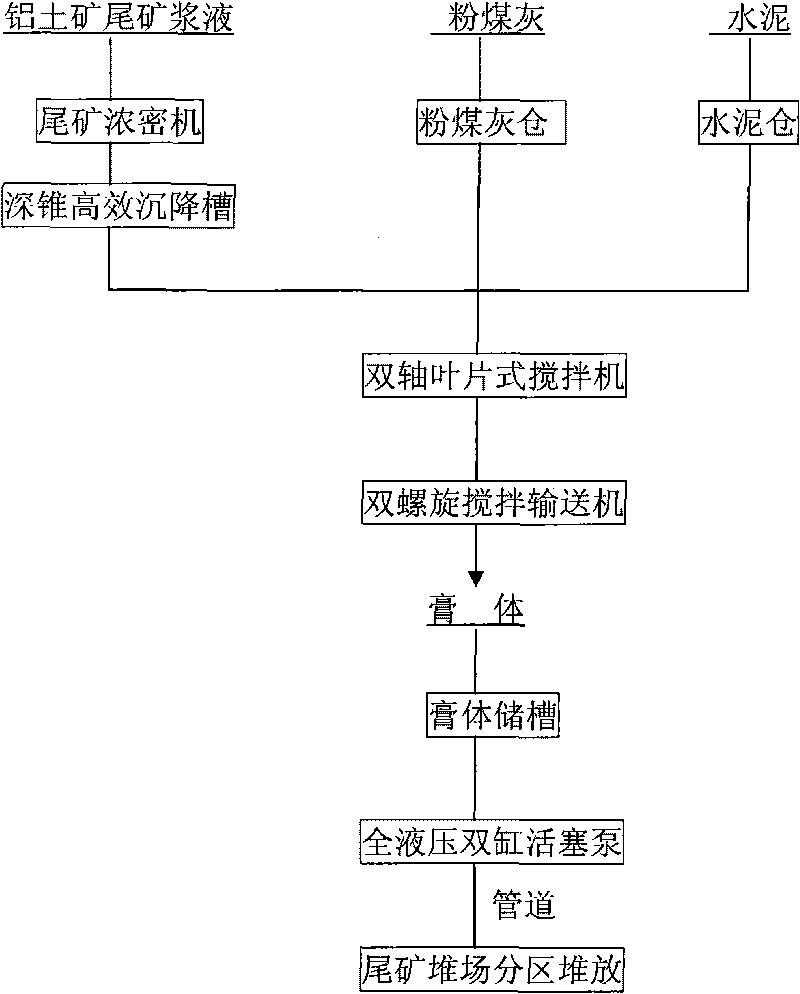

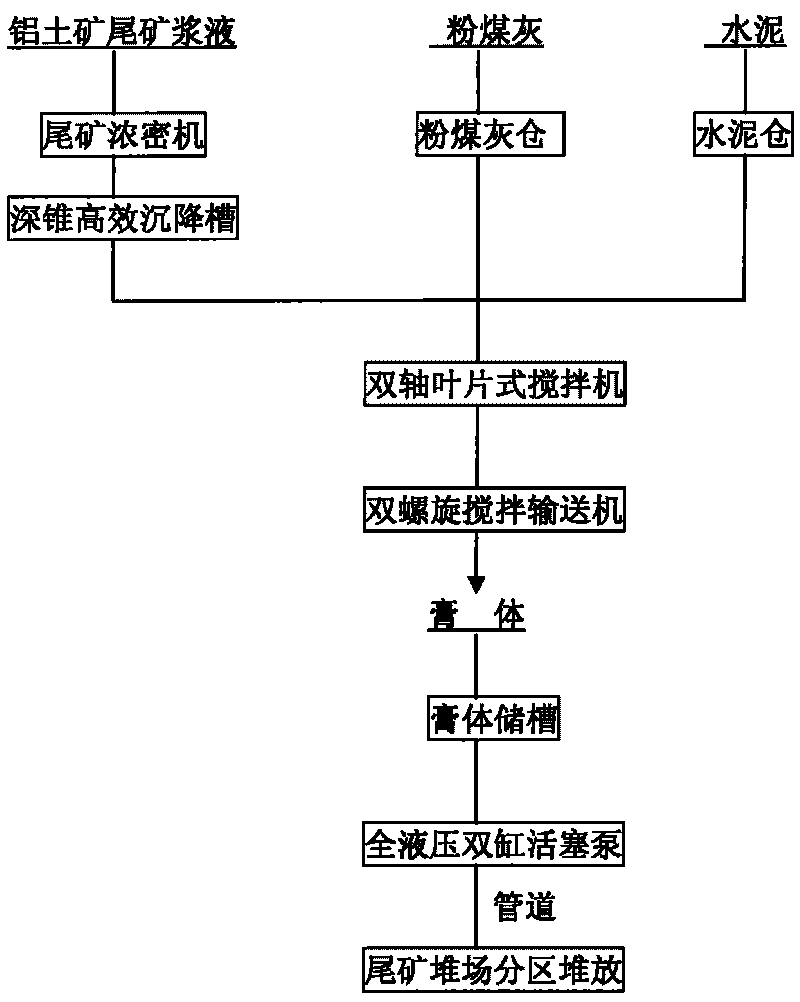

Image

Examples

Embodiment 1

[0034] After the bauxite tailings slurry is concentrated to a solid weight concentration of 40% by using a two-stage concentration process of a thickener and a deep cone high-efficiency settling tank, base material powder with pozzolanic activity or potential hydraulicity is added Coal ash, granulated blast furnace cinder, coal gangue, red mud, silica fume, volcanic ash, pumice, any one and / or mixture of several kinds, the addition amount is 10% of the weight of dry tailings; gelling activator cement, lime , gypsum, water glass and / or several mixtures, the addition amount is 1% of the weight of the dry tailings, and the two-stage agitation of the combination of the twin-shaft blade mixer and the double-screw agitation conveyor is used to prepare the mixture. The uniform paste with a solid weight concentration of 40% 0% and a slump of 20 cm cm is transported to the storage yard by the paste, and is condensed to form a hardened accumulation body for stacking.

Embodiment 2

[0036] After the bauxite tailings slurry is concentrated to a solid weight concentration of 55% by using a two-stage concentration process of a thickener and a deep cone high-efficiency settling tank, base material powder with pozzolanic activity or potential hydraulicity is added Coal ash, granulated blast furnace cinder, coal gangue, red mud, silica fume, volcanic ash, pumice, any one and / or mixture of several kinds, the addition amount is 50% of the weight of dry tailings; gelling activator cement, lime , gypsum, water glass, any one and / or a mixture of several kinds, the addition amount is 10% of the weight of dry tailings, and it is prepared by two-stage stirring with a combination of a twin-shaft blade mixer and a double-screw mixing conveyor. A uniform paste with a solid weight concentration of 60% and a slump of 28 cm is produced, and the paste is transported to the stockyard for condensation to form a hardened accumulation body for stacking.

Embodiment 3

[0038] The bauxite tailings slurry with a weight concentration of 12% is concentrated by a thickener to a weight concentration of 25%, and then concentrated through a deep cone high-efficiency settling tank to obtain a high-concentration bauxite tailings slurry with a weight concentration of 45%. The high-concentration bauxite tailings slurry, fly ash and cement from the silo are sent to the double-shaft blade mixer for primary mixing, and then enter the double-screw mixing conveyor for secondary strong mixing to prepare the weight concentration 51%, a uniform paste with a slump of 23cm. The amount of fly ash added is 35% of the weight of the dry tailings, and the amount of cement added is 2% of the weight of the dry tailings. The paste is sent into the paste storage tank, and the paste is pressed into the pipeline by the full hydraulic double-cylinder piston pump to be transported to the storage yard. The paste is piled up in four areas in the stockyard, and condenses to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com