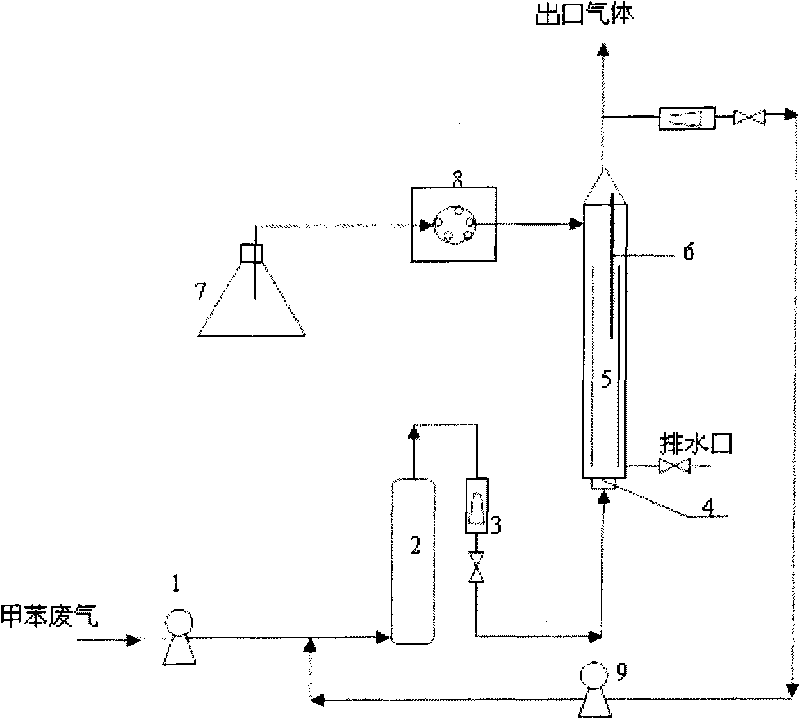

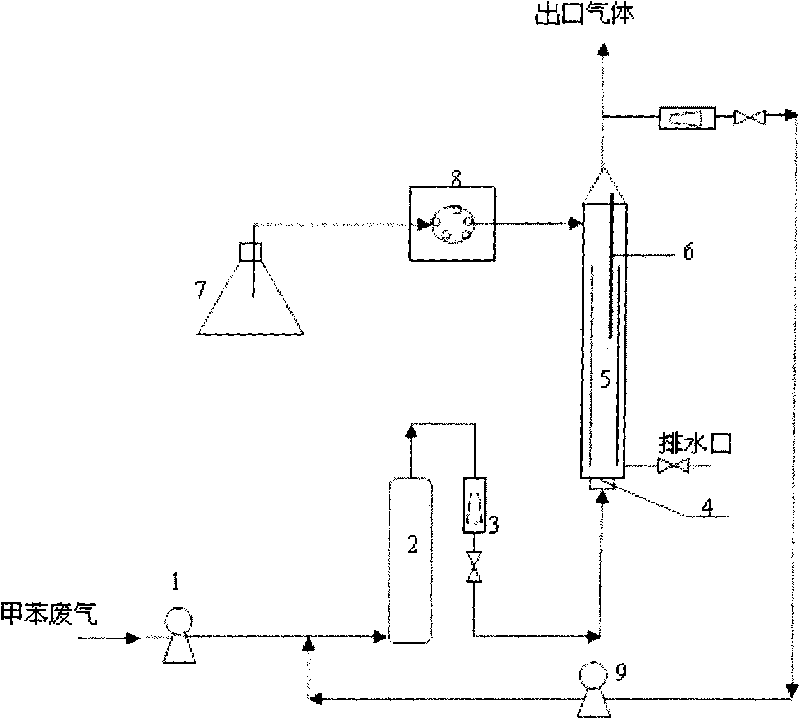

Apparatus and method of airlift three-phase loop bio-reactor for purifying toluene waste gas

A bioreactor, airlift technology, applied in the field of airlift three-phase loop bioreactor purification devices, can solve the problems of rise, bed clogging pressure drop, complex structure and operation of biological trickling filter, etc. Simple structure, stable purification process, and the effect of enhancing the flexibility of equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

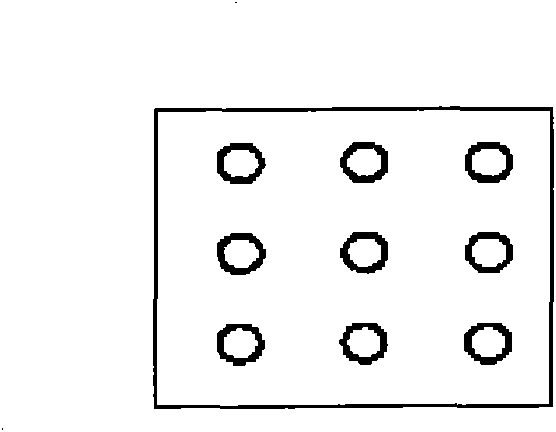

[0023] The concentration of toluene is 200mg / m 3 , the flow rate is 0.52m 3 The toluene exhaust gas per hour is passed into the air-lift three-phase circulation bioreactor with a height-to-diameter ratio of 10:1, a cross-sectional square side length of 0.12m, a draft tube with a height-to-diameter ratio of 10:1, and a cross-sectional square side length of 0.08m. Among them, the aperture of the gas distribution plate is 0.5mm, the amount of immobilized bacteria is 30% of the working volume of the three-phase bioreactor of the bubble tower, and the amount of the inorganic salt medium is 70% of the working volume of the three-phase bioreactor of the bubble tower , the pH value of the inorganic salt medium is 7.2, and the NH in the inorganic salt medium 4 Cl, KH 2 PO 4 , MgSO 4 ·7H 2 O, CaCl 2 , FeSO 4 ·7H 2 O concentrations were 7.5, 1.5, 0.4, 0.18, 0.07mmol / L, MnSO 4 ·H 2 O, ZnSO 4 、Na 2 MoO 4 ·7H 2 O, CuSO 4 ·5H 2 O, CoCl 2 ·6H 2 O is a trace amount, the inorg...

Embodiment 2

[0025] The concentration of toluene is 400mg / m 3 , the flow rate is 0.78m 3 The toluene waste gas per hour is passed into the air-lift three-phase circulation bioreactor with a height-to-diameter ratio of 11:1, a cross-sectional square side length of 0.15m, a draft tube with a height-to-diameter ratio of 11:1, and a cross-sectional square side length of 0.11m. Among them, the aperture of the gas distribution plate is 3mm, the amount of immobilized bacteria is 35% of the working volume of the three-phase bioreactor of the bubble tower, and the amount of the inorganic salt medium is 65% of the working volume of the three-phase bioreactor of the bubble tower. In inorganic salt medium (NH 4 ) 2 SO 4 、K 2 HPO 4 , MgCl 2 , CaCl 2 , FeCl 2 4H 2 O concentrations were 8, 3, 0.8, 0.3, 0.15mmol / L, MnSO 4 ·H 2 O, ZnCl 2 、Na 2 MoO 4 ·7H 2 O, CuCl 2 2H 2 O. CoSO 4 ·7H 2 O is a trace amount, and the temperature in the airlift three-phase circulation bioreactor is maintaine...

Embodiment 3

[0027] The concentration of toluene is 800mg / m 3 , the flow rate is 1.04m 3 The waste gas of toluene / h enters the air-lift three-phase circulation bioreactor with a height-to-diameter ratio of 12:1, a cross-sectional square side length of 0.2m, a draft tube with a height-to-diameter ratio of 12:1, and a cross-sectional square side length of 0.15m. Among them, the aperture of the air distribution plate is 4.5mm, the amount of immobilized bacteria is 40% of the working volume of the three-phase bioreactor of the bubble tower, and the amount of the inorganic salt medium is 60% of the working volume of the three-phase bioreactor of the bubble tower , NH in inorganic salt medium 4 Cl, (NH 4 ) 2 SO 4 、KH 2 PO 4 、K 2 HPO 4 , MgSO 4 ·7H 2 O, MgCl 2 , CaCl 2 , FeCl 2 4H 2 O, FeSO 4 ·7H 2 O concentrations were 16.5, 3, 3, 1.5, 0.6, 0.4, 0.5, 0.1, 0.1mmol / L, MnSO 4 ·H 2 O, ZnSO 4 、Na 2 MoO 4 ·7H 2 O, CuSO 4 ·5H 2 O, CoCl 2 ·6H 2 O is a trace amount, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com