Fiber-reinforcement silicon dioxide aerogel continuous felt and preparation method thereof

A technology of airgel continuous felt and silica, which is applied in the field of airgel materials and its preparation, can solve the difficulty of meeting the needs of the preparation and use of general heat insulation materials, the inability to efficiently prepare airgel material continuous felt, Airgel is used as a material for high production costs to achieve the effect of preventing solid heat transfer and air convection heat transfer, low cost, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

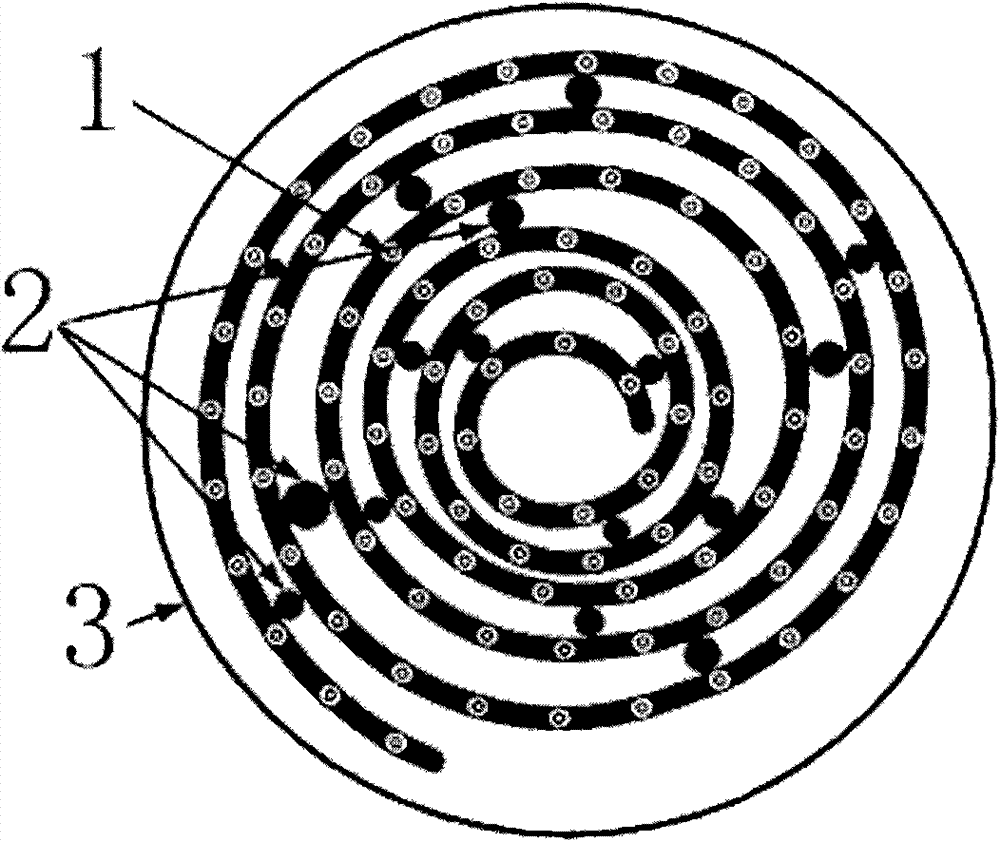

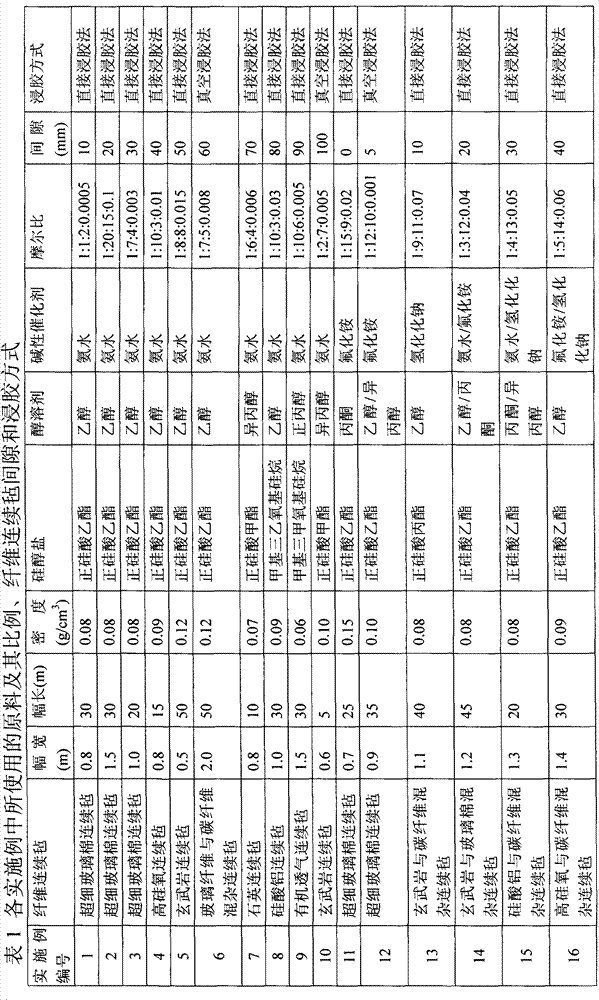

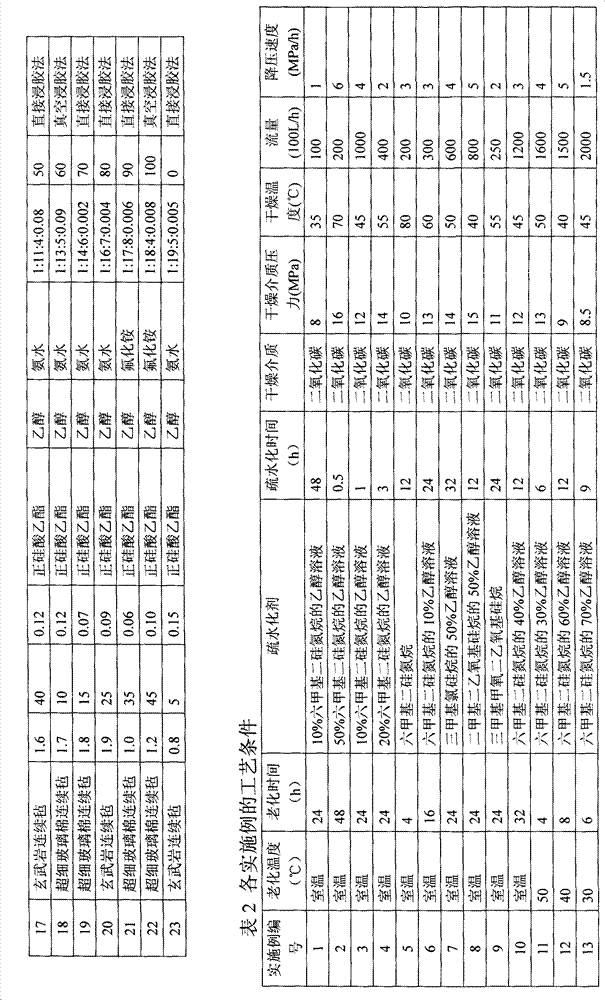

Embodiment 1

[0078] First, the ultra-fine glass wool continuous mat with a width of 0.8 meters, a width of 30 meters, and a density of 0.08 g / cubic centimeter (the fiber material involved in this article comes from Shandong Luyang Co., Ltd.) in the winding process equipment (see figure 1 ) into a winding unit, the gap between the continuous mats is 10mm; then tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water are prepared in a molar ratio of 1:1:2:0.0005 silica sol (all the chemical reagents involved in this article are the reagents produced by Beijing Chemical Reagent Factory, the same below); and then adopt the direct dipping method (that is, adding the silica sol into the container that is placed with the winding unit, relying on diffusion to realize Immersion of silica sol, hereinafter the same) The prepared silica sol is immersed in the coiling unit; then aged at room temperature for 24 hours; then 10% ethanol solution of hexamethyldisilazane is used for surf...

Embodiment 2

[0080] First, a continuous mat of ultra-fine glass wool with a width of 1.5 meters, a length of 30 meters and a density of 0.08 g / cubic centimeter is wound into a winding unit on the winding process equipment, and the gap between the continuous mats is 20 mm; Then prepare silica sol with tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water in a molar ratio of 1:20:15:0.1; then use the direct dipping method to immerse the prepared silica sol into the winding unit; then in Aging at room temperature for 48 hours; then use 50% hexamethyldisilazane ethanol solution for 0.5 hours of surface treatment; then put it into an autoclave, inject 16 MPa carbon dioxide gas, at 70 ° C at 2000 liters / hour The flow rate of the ethanol will bring the ethanol into the separation tank for separation. After the ethanol is completely separated, the pressure will be released slowly at a rate of 6 MPa / hour until it is balanced with the external atmospheric pressure. Finally, ...

Embodiment 3

[0082] Firstly, a continuous mat of ultra-fine glass wool with a width of 1.0 meters, a length of 20 meters and a density of 0.08 g / cubic centimeter is wound into a winding unit on the winding process equipment, and the gap between the continuous mats is 30mm ; Then prepare silica sol with tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia in a molar ratio of 1:7:4:0.003; then use the direct dipping method to immerse the prepared silica sol into the winding unit; then Aging at room temperature for 24 hours; then use 10% hexamethyldisilazane ethanol solution to carry out surface treatment for 1 hour; The hourly flow rate brings ethanol into the separation tank for separation. After the ethanol is completely separated, the pressure is slowly released at a rate of 4 MPa / hour until it is balanced with the external atmospheric pressure. Finally, the winding unit is taken out and the obtained fiber reinforced The silica airgel continuous mat is removed from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com