Compound bottom sheet of magnetic induction heating cooker

A magnetic induction and cooking utensil technology, applied in the mechanical field, can solve problems such as deformation, expansion and deformation of the bottom of the metal sheet, etc., and achieve the effects of stable structure, reduced thermal deformation, and avoiding abnormal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

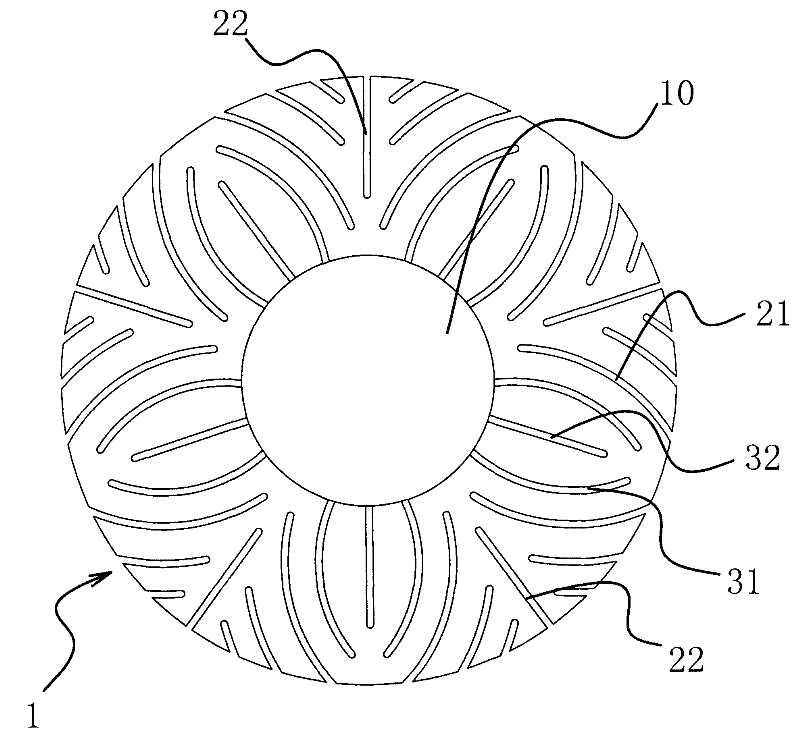

[0024] Such as figure 1 As shown, the complex bottom sheet of the magnetic induction heating cooker is arranged at the bottom of the cooker, and includes a sheet body 1 made of a magnetically conductive material. In this embodiment, the sheet body 1 is made of stainless steel. The sheet body 1 is made of a sheet material, and a central hole 10 is hollowed out in the center of the sheet material, and the entire sheet body 1 is circular. The outer edge of the sheet body 1 is provided with a plurality of outer through holes opening toward the outside and extending inward, and the inner edge of the sheet body 1 is provided with a plurality of inner through holes opening toward the inner side and extending outward.

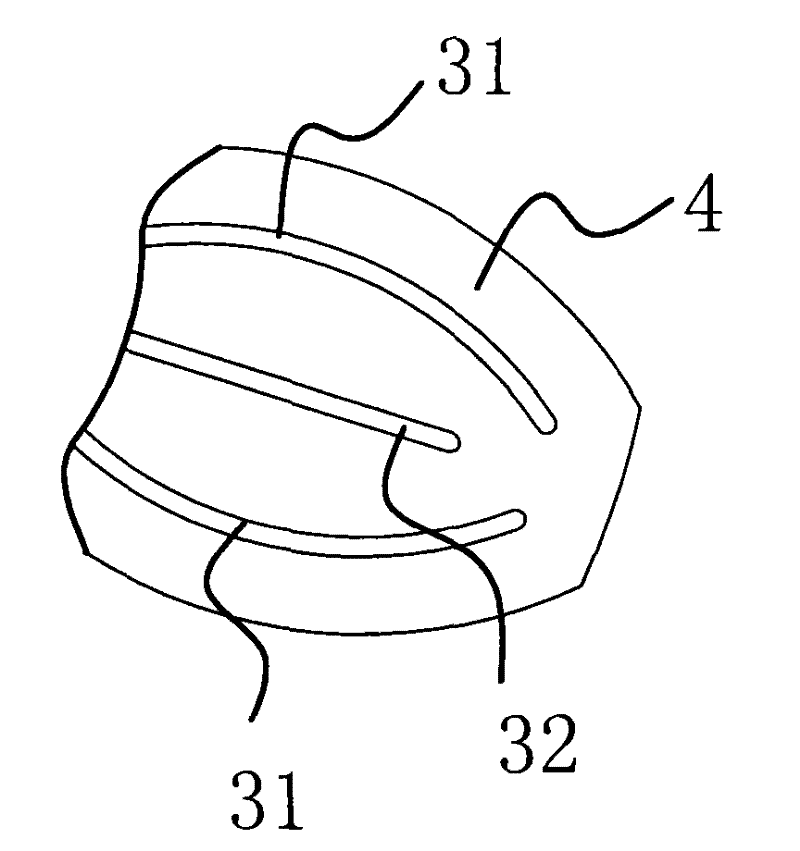

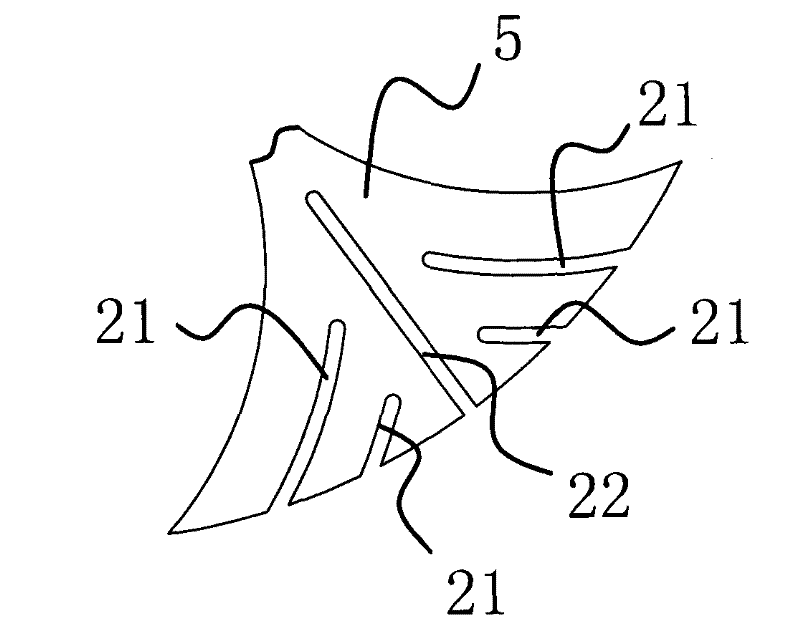

[0025] Such as Figure 1-3 As shown, the outer through-holes include several arc-shaped outer through-holes 21, and the above-mentioned arc-shaped outer through-holes 21 divide the entire sheet 1 into several lotus petal-shaped regions 4 and ginkgo leaf-shaped region...

Embodiment 2

[0028] Such as Figure 4 As shown, in this embodiment, the outer through holes include several straight outer through holes 22 uniformly distributed in the circumferential direction, and the inner through holes include several straight inner through holes 32 evenly distributed in the circumferential direction. Each straight outer through hole 22 and each straight inner through hole 32 are arranged alternately. The lengths of the straight outer through holes 22 are equal, the lengths of the straight inner through holes 32 are equal, and the sum of the lengths of a straight outer through hole 22 and a straight inner through hole 32 is equal to the width of the sheet body 1 . The rest are similar to those in Example 1, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com