Ultra-high molecular weight polyethylene/polyvinyl chloride composite pipe and its manufacturing method

An ultra-high molecular weight, polyvinyl chloride technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve problems that are difficult to meet sanitary technical standards, wear resistance, anti-adhesion, solvent resistance, etc. Problems such as high production costs are achieved to solve complex composite processes and low composite strength, highlighting substantive features, and simple manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

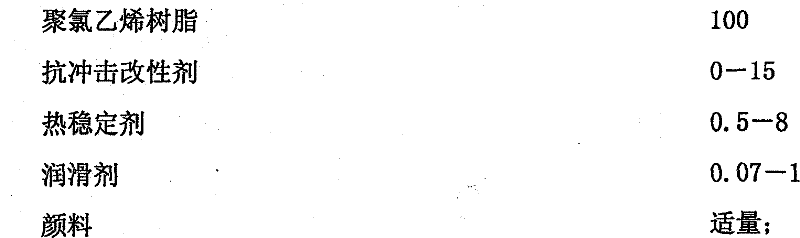

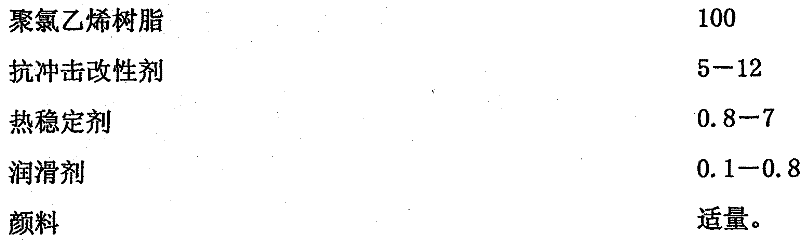

Method used

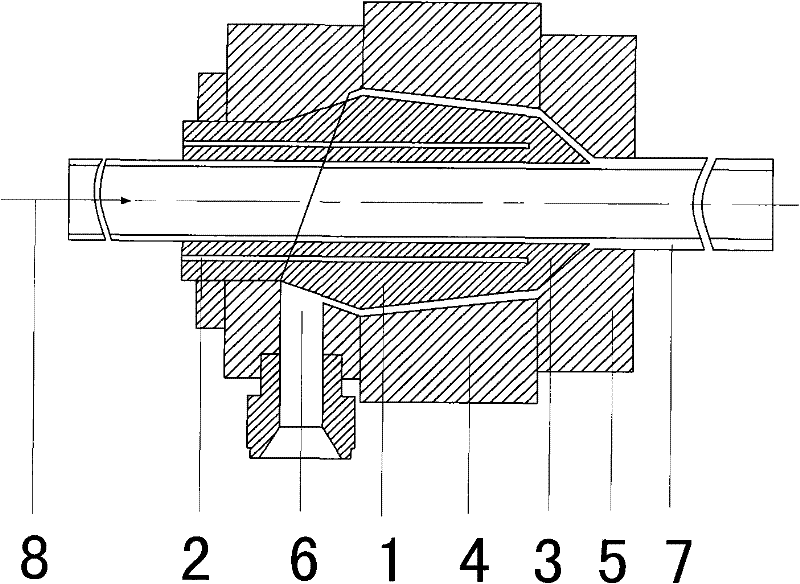

Image

Examples

Embodiment 1

[0061] Example 1 Manufacture of an ultra-high molecular weight polyethylene modified polyvinyl chloride composite pipe with an outer diameter of 110 mm and an inner diameter of 96 mm

[0062] It is characterized in that comprising the steps of:

[0063] a. Manufacture of UHMWPE inner tube

[0064] ① Ingredients

[0065] Accurately weigh 50 kilograms of ultra-high molecular weight polyethylene (UHMWPE) with a viscosity-average molecular weight of 2,500,000, 2.5 kilograms of polyethylene wax with a molecular weight of 3000-5000 and mix well, for subsequent use;

[0066] ②Extrusion molding

[0067] Send the ultra-high molecular weight polyethylene and polyethylene wax mixture uniformly mixed in step ① into the screw extruder, and extrude through a pipe die. The main operating conditions are:

[0068] Cylinder temperature, ℃

[0069] District 1 120, District 2 160, District 3 150, District 4 190;

[0070] mold temperature, ℃

[0071] District 1 160, District 2 190, District ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com