Waste water evaporating device and method using same

A treatment device and wastewater technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unfavorable desulfurization wastewater reuse, adverse environmental impact, complex process, etc. The effect of small area, space saving and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

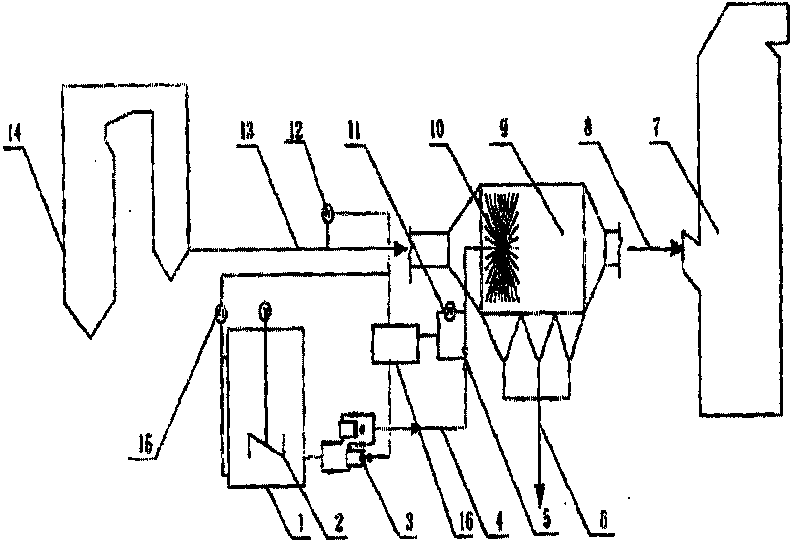

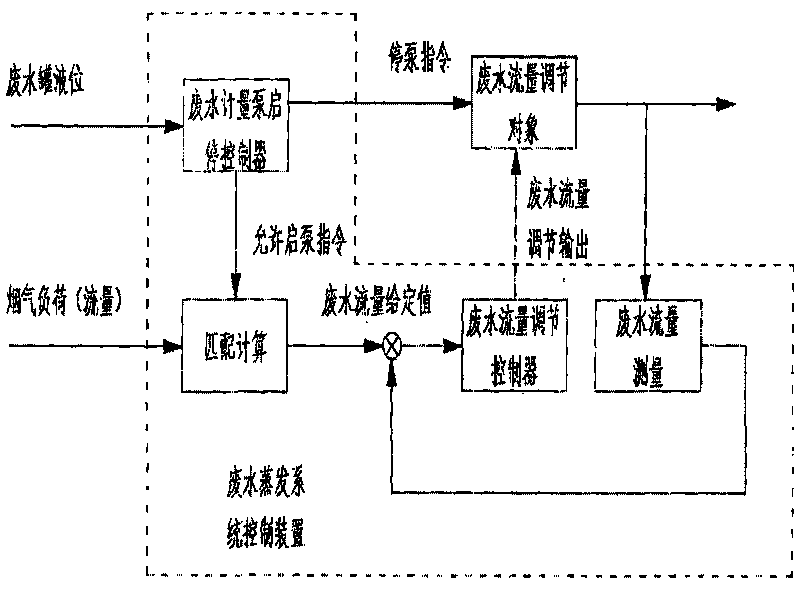

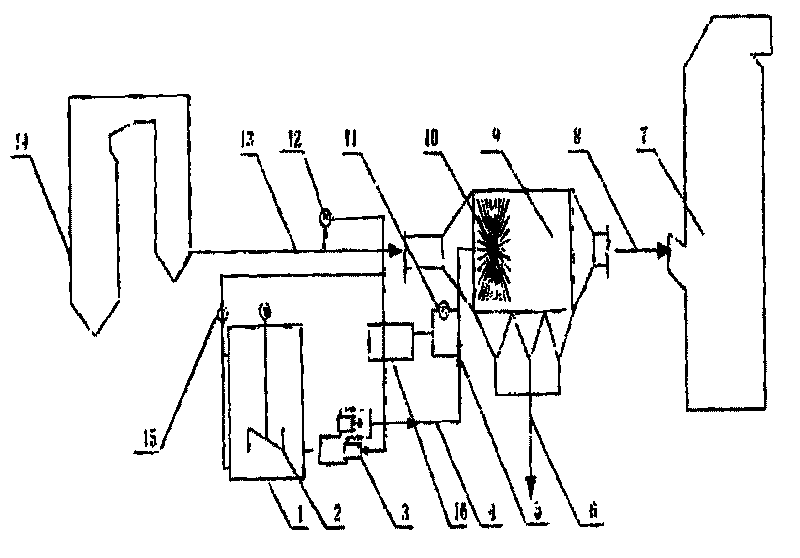

[0013] Please refer to figure 1 As shown, the waste water evaporation treatment device of the present invention includes a waste water tank 1, a waste water metering pump 3 connected to the waste water tank 1, a waste water conveying pipeline 4 drawn from the waste water metering pump 3, and an atomizing atomizer connected to the waste water conveying pipeline 4. The nozzle 10, the electrostatic precipitator 9 containing the atomizing nozzle 10, the raw flue gas channel 13 connected to one end of the electrostatic precipitator 9 for inputting raw flue gas, the desulfurization absorption tower 7 connected to the other end of the electrostatic precipitator 9 and the connection The precipitated solid conveying pipeline 6 of the electrostatic precipitator 9 , and the raw flue gas is provided by the boiler 14 .

[0014] The waste water delivery pipeline 4 is provided with a nozzle regulating valve 5 . The wastewater evaporation treatment device of the present invention is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com