Tiny discharge gap bi-feedback adaptive analytic fuzzy servo control method

A discharge gap, servo control technology, applied in circuits, manufacturing tools, electric processing equipment, etc., can solve problems such as difficult control, and achieve the effect of improving performance and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

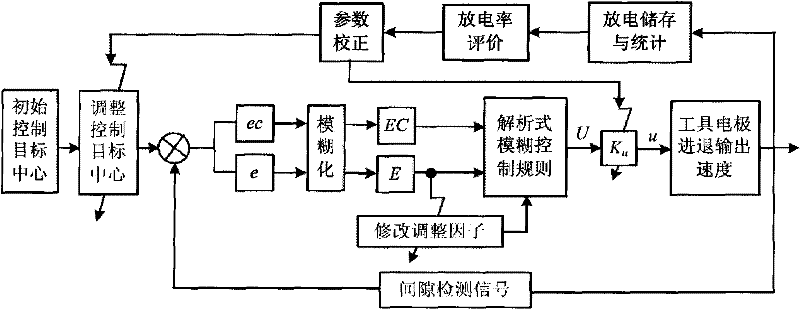

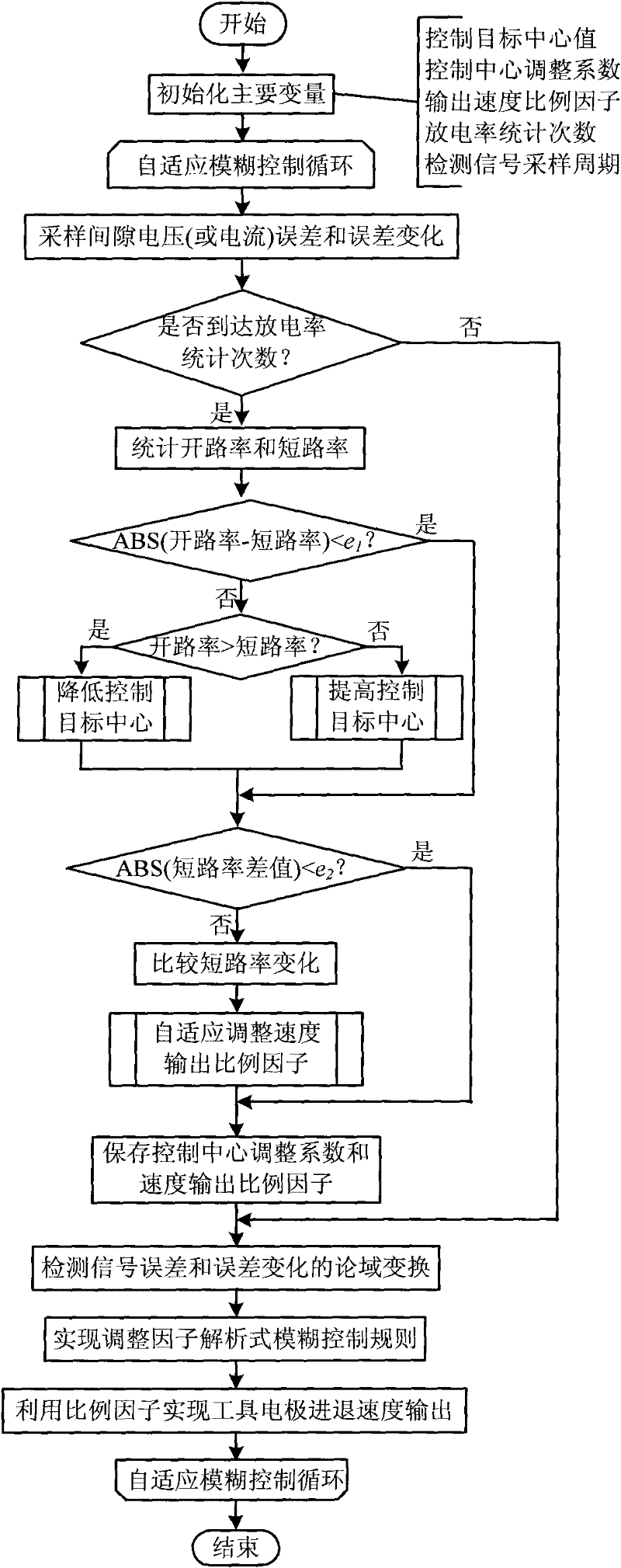

[0038]The present invention provides a dual-feedback self-adaptive analytical fuzzy servo control method for tiny discharge gaps. The present invention will be further described below through the description of drawings and specific implementation methods.

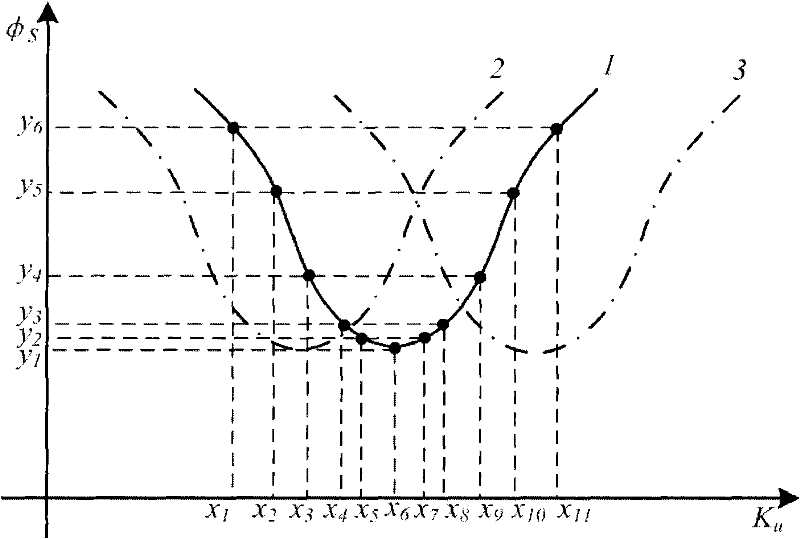

[0039] In order to illustrate the superiority and specific implementation of the control method of the present invention, the basic principle of the control method is firstly described. Then, it focuses on the design of analytical fuzzy controller, the adaptive transfer algorithm of the control target center, and the adaptive adjustment algorithm of the output speed scale factor. Finally, the specific implementation process of the double feedback adaptive analytical fuzzy servo control software is given.

[0040] 1. Explain the basic principle of double feedback adaptive analytical fuzzy servo control method

[0041] The normal discharge rate is difficult to determine and measure, but the sum of the open circuit rate, nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com