Electric spark and electrolysis combined milling machining method of micro three-dimensional structure

A technology of milling processing and three-dimensional structure, which is applied in the direction of processing working media, etc., can solve the problems of reducing processing efficiency and achieve the effect of reducing control difficulty, good surface quality, high efficiency and high precision three-dimensional micromachining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is achieved through the following technical solutions:

[0026] 1) First use CAD / CAM software for micro-3D structure modeling, process allowance allocation, trajectory planning, and finally generate

[0027] into the machining codes of micro-EDM and micro-electrolytic machining processes;

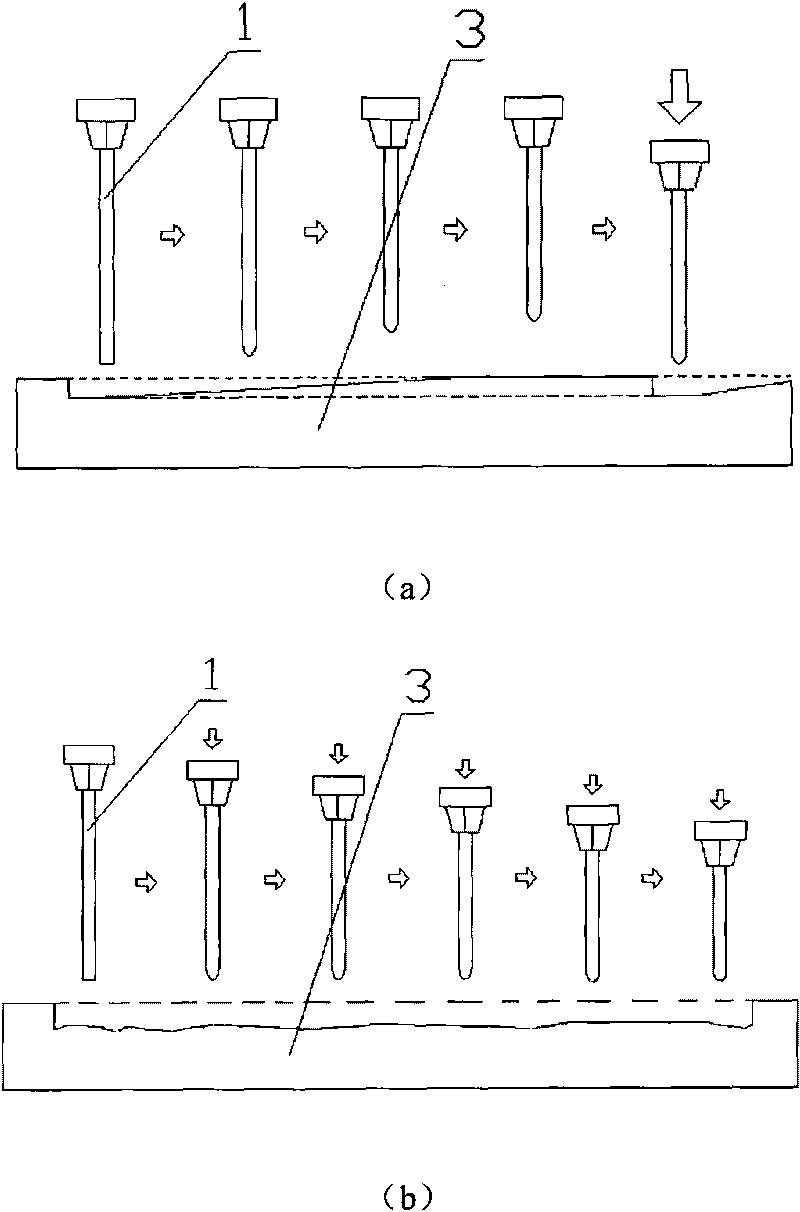

[0028] 2) Then adopt the closed-loop control method of gap servo scanning, in the pure water machining medium, according to the predetermined machining trajectory, adopt larger electric discharge machining parameters, continuously and quickly complete the micro electric spark milling with large process margin;

[0029] 3) Replace the processing fluid with a low-concentration electrolyte, replace the processing electrodes with side wall insulation electrodes, complete layer-by-layer electrolytic milling according to the predetermined processing trajectory and scanning speed, adopt an open-loop control method, and do not close the loop for current and voltage gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com