Grounding method for composite insulating pole tower of power transmission line and pole tower thereof

A technology of composite materials and transmission lines, applied in the configuration of grounding wires, connecting contact materials, etc., can solve the problem that the lightning protection line has no direct grounding path, and achieve the effect of less possibility of being stolen, lower cost, and save width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

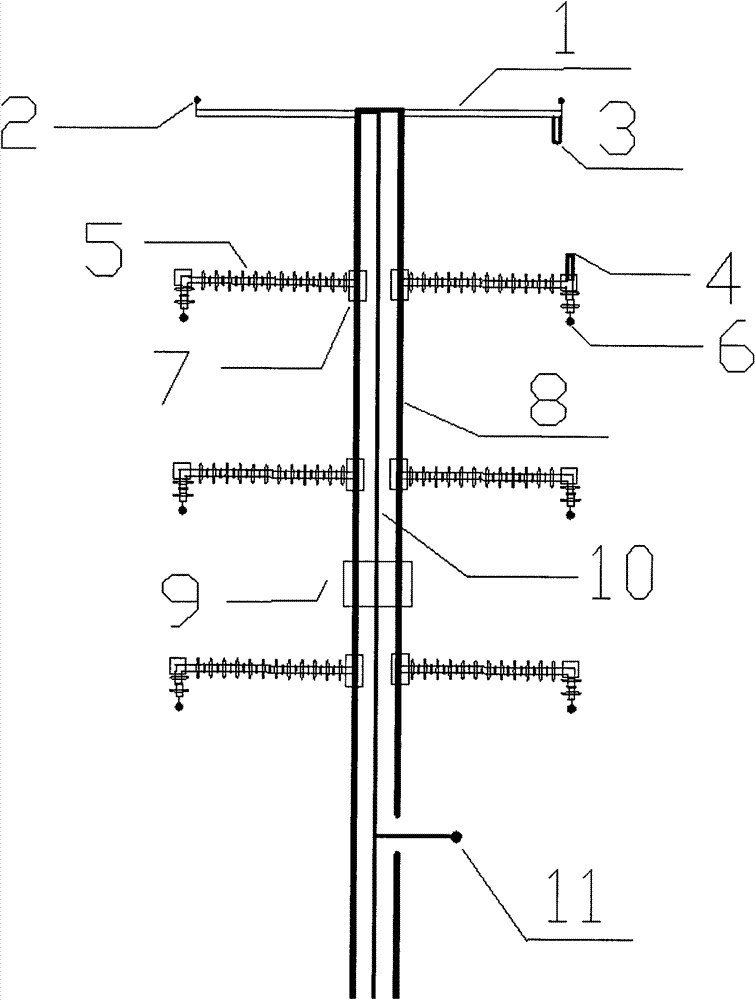

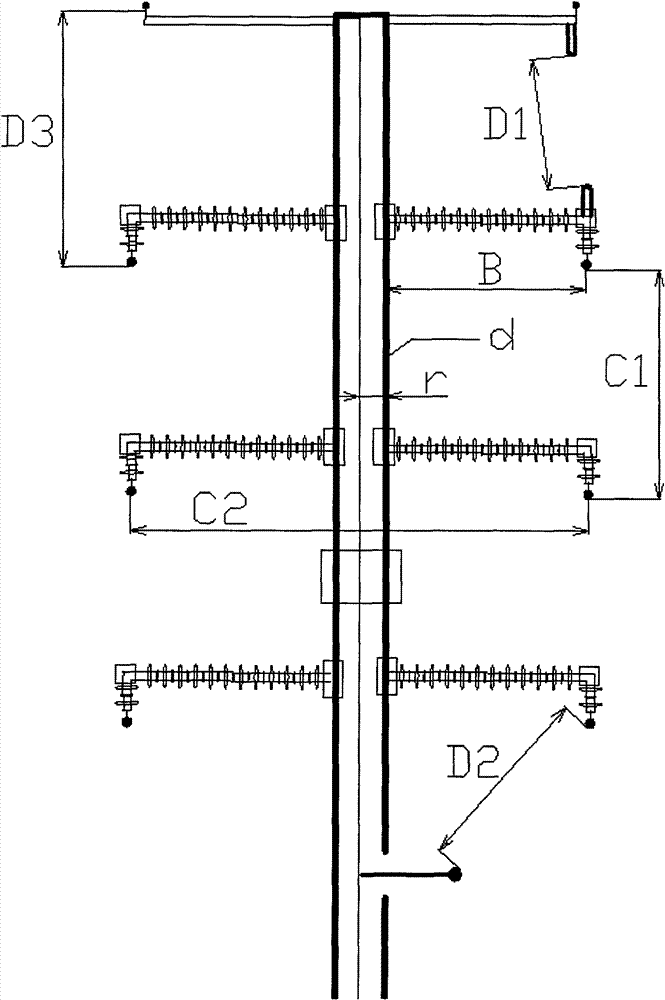

[0024] 110kV transmission line composite tower, can adopt the above grounding method. like figure 2 As shown, the main technical parameters of the tower can take the following values: C1=3.5m, C2=3.0m, r≈0.2m, B≈1.5m, d=10mm, D1=1.5m, D3=3.0m, cancel D2, that is Do not drill holes in the shaft to install down-conductor electrodes. With this scheme, firstly, the gap distance between towers meets the design requirements of 110kV line, and can meet the operation requirements of 110kV line in terms of electrical performance; secondly, it also has the following advantages:

[0025] (1) Using this grounding method effectively utilizes the insulation of the shaft and provides lightning overvoltage flashover clearance;

[0026] The 110kV phase-to-ground insulation distance is mainly controlled by lightning overvoltage, and it is dominated by lightning strikes. The phase-to-ground insulation of composite rods mainly includes: air gap insulation with a distance of D1 (1.5m), and com...

Embodiment 2

[0038] 220kV transmission line composite tower, can adopt the above grounding method. like figure 2 As shown, the main technical parameters of the tower can take the following values: C1=5.5m, C2=5.0m, r≈0.3m, B≈2.4m, d=15mm, D1=2.5m, D3=5.0m, D2=2.7m . Firstly, the gap distance between towers meets the design requirements of 110kV line, and can meet the operation requirements of 220kV line in terms of electrical performance; secondly, it also has the following advantages:

[0039] (1) Using this grounding method effectively utilizes the insulation of the shaft and provides lightning overvoltage flashover clearance;

[0040] The 220kV phase-to-ground insulation distance is mainly controlled by lightning overvoltage. The phase-to-ground insulation of composite material rods mainly includes: air gap insulation with a distance of D1 (2.5m), air gap insulation with a distance of D2 (2.7m), and air gap and thickness with a distance of (r+B) (2.7m) Combination insulation of ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com